| Author |

Topic Topic  |

|

Invernahaille

|

Posted -

26/06/2006

:

04:02 Posted -

26/06/2006

:

04:02

|

Edited by - Invernahaille on 10 April 2007 04:41:19

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 05/07/2006 : 18:07 Posted - 05/07/2006 : 18:07

I liked that P. He never asked me for a rotating shaft, that would have been dead easy, just half inch rod in hangers and a threaded end in a nut on the bell crank. But he didn't and never argued with my drawings which as Peter said converted the motion to push and pull on the rod by making a double start square thread in a threaded sleeve rotated by the speed wheel. Far better arrangement as it would never wear out, no lost motion with torque on 15 feet of half inch bar and a simpler arrangement of the fulcrum points. Being double start it was a quick thread as well. Anyone who has made a threaded sleeve like that knows how much work there is in it. The bottom line was that the owner had no experience with the things he reckoned to be an expert on and didn't trust anyone else's experience unless they had a bagfull of qualifications. I never saw the replacement linkage but it was nowhere near as good as mine due to the design.

Mind you, it's amazing the number of people that I have met who run Gardners and have no idea about how they actually work and the relationship between the governor and the injection pumps (that design has a separate pump for each injector). Even more common was ignorance of the fact that the drive to the governor and the pumps incorporates a helical gear and this is rotated by the governor control. The effect is that the lower the demand setting on the governor, the more retarded the injection. The idea of this was that in road transport applications, at full revs and torque, say climbing a hill, as the engine died back you lifted your foot on the accellerator thus allowing the governor rod to come back to the speed setting that the engine was restrained to by the load. This retarded the engine and it was a very strange feeling to feel the engine pulling away up the hill as you lifted your foot. Exactly the same as pressing the brake pedal when your brakes have gone, you feel as though you have actually accellerated. There was another hidden goody on many Gardner installations. They had a clutch brake. The big problem when changing up a gear while still going uphill with a big engine and a crash or constant mesh box is that the wagon slows down quicker than the engine and you can't get the gear in. With a clutch brake, the last inch of travel on the clutch pedal applied a brake to the flywheel and this meant you could bring the engine speed down and make faster changes. The sooner you got the power back on the better you got on. We used to have an old Albion with no clutch brake and the rule when changing was ruefully described to me once as 'wait while two lamposts have gone by'. Not quite as bad as that but it felt like it!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Another

Traycle Mine Overseer

6250 Posts

|

|

Posted - 05/07/2006 : 19:44 Posted - 05/07/2006 : 19:44

Inver..lovely pictures. Keep 'em coming. Nolic

" I'm a self made man who worships his creator"   |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 06/07/2006 : 06:01 Posted - 06/07/2006 : 06:01

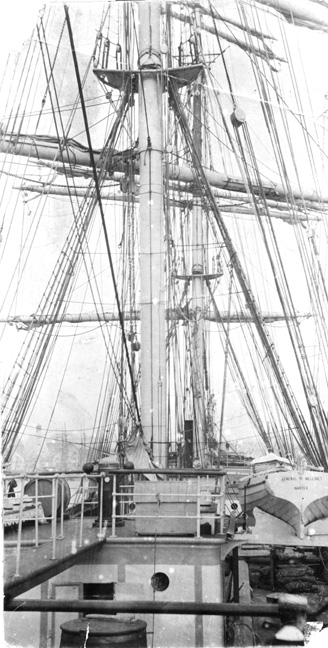

Photo found in a book, 'Stationary Engine Driving' presented to Herbert Dewhurst of 29 Clarence Street, Barnoldswick in 1917. It was second prize for regular attendance from Rainhall Road Wesleyan Sunday School. The name on the lifeboat is 'General Mellinet. Nantes.

I tried searching for details because there looks to be a small funnel behind the masts but had no success.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 06/07/2006 : 17:48 Posted - 06/07/2006 : 17:48

Right..... can we have the bottom line in English?

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Ringo

Site Administrator

3793 Posts

|

|

Posted - 06/07/2006 : 17:56 Posted - 06/07/2006 : 17:56

Le LANCEMENT du GENERAL MELLINET le samedi 15 décembre 1894, premier navire construit par les Chantiers de Normandie, est un événement considérable pour l'agglomération rouennaise. La marraine du navire est la femme de l'armateur, Mme Olivier, le parrain est Monsieur Lihoreau, notable nantais. Le capitaine Bachelier prend le commandement du navire dès sa mise en service, en 1895. Le trois-mâts effectue un premier voyage retentissant en couvrant la distance Swansea-San-Francisco en 129 jours. La meilleure traversée du voilier est effectuée en 1901 : Le GENERAL MELLINET met 118 jours pour rallier Portland, Oregon, à Dunkerque. Mais le navire est vendu en 1905 à l'armement Bröving, de Norvège. Il prend alors le nom de GUNVOR. Le 6 avril 1912, chargé de nitrate en provenance du Chili, le voilier touche les récifs à la pointe de Black-Head et sombre devant Falmouth, pointe sud-ouest de l'Angleterre. En se glissant sur le bout-dehors, la totalité de son équipage parvient cependant à atteindre la terre ferme

LAUNCHING of the GENERAL MELLINET saturdays December 15, 1894, first ship built by the Building sites of Normandy, is a considerable event for the agglomeration rouennaise. The godmother of the ship is the woman of the ship-owner, Mrs. Olivier, the godfather is Mr Lihoreau, notable Nantes. The Bachelier captain takes the command of the ship as of his startup, in 1895. The three-masted ship accomplishes a first resounding voyage while covering the Swansea-San-Francisco distance in 129 days. Best crossed sailing ship is carried out in 1901: The GENERAL MELLINET spends 118 days to rejoin Portland, Oregon, in Dunkirk. But the ship is sold in 1905 with the Bröving armament, of Norway. It takes the name of GUNVOR then. 6 April 1912, charged with nitrate coming from Chile, the sailing ship touches the reefs with the point of Black-Head and dark in front of Falmouth, point south-western of England. While slipping on the boom, the totality of its crew however manages to reach the firm ground

|

Ringo

Site Administrator

3793 Posts

|

|

Posted - 06/07/2006 : 18:17 Posted - 06/07/2006 : 18:17

quote:

Invernahaille wrote:

Ringo, sou Francais est bonne.

no, i Know a good translation site

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 07/07/2006 : 07:42 Posted - 07/07/2006 : 07:42

I watched a ship going through the lock many years ago. It was a very tight fit and as it moved off after the lift the mast brought down the overhead cables, Telephone I think, no problem at all, the mast didn't even bend.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 07/07/2006 : 16:06 Posted - 07/07/2006 : 16:06

I've looked up the lock where this happened, and I think it was Latchford lock. You came down a steep hill directly towards the locks and then we turned left to get to Rigby's Dairy where we tanked milk to. I always remember it because when I first went there the instructions I was given were to turn left at the block of modern flats. It was a couple of years before I went down when there was a ship in the lock and I realised whet the block of flats was, it was the upperworks of a large ship. This was the one that brought down the overhead cable.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 07/07/2006 : 16:44 Posted - 07/07/2006 : 16:44

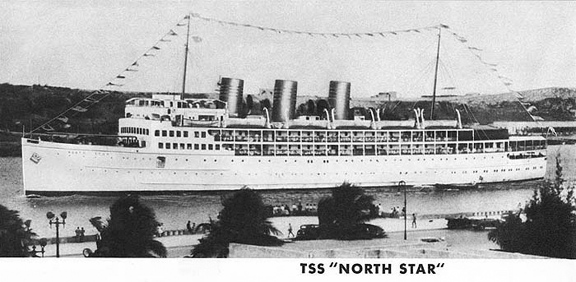

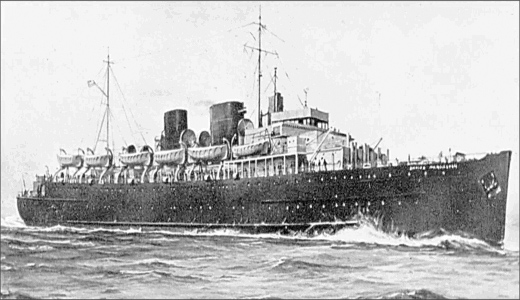

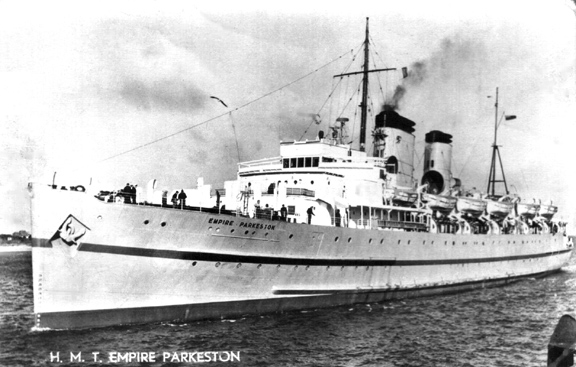

You've got my mind working on ships and I looked up an old friend of mine, the Empire Parkeston which was the troopship that took us over the the Hook of Holland and back in the days when we were holding back the Mongolian Hordes in Berlin. Here's what I found on the web: H.M.C.S. PRINCE HENRY

She was built , like her two sisters in 1930 and arrived at Vancouver on the 21st of June 1930. In 1938 she was sold to Clark Steamship Co. for $500,000 and renamed NORTH STAR. In 1939 she was requisitioned by the Admiralty and transformed into an Armed Merchant Cruiser (AMC) and renamed H.M.S. PRINCE HENRY. She was commissioned on the 4th of December 1940. In 1943 she was again taken into Dockyard hands and converted from the AMC into a Landing Ship (Infantry) LS(I) carrying 444 Troops. On the 2nd June the Canadian Troops of the 3rd Infantry Div. boarded her in Berth 37, Southampton Docks on the south coast of England as part of the assault Group J.4. This included 147 Canadian/Scottish and 128 Support Troops. On the 5th June at 21.10 hours they headed out from their anchorage in Area 18 off the town of Cowes on the Isle of Wight and slipped down the waters of the Solent and out into the English Channel bound for 'JUNO' Beach on the coast of Normandy in occupied France. After a choppy crossing with other ships of the invasion fleet she arrived and anchored off the hamlet of Courseulles and waited to launch her Landing Craft. Off shore lay rocky shoals so rather than try to find a gap through them the Canadians chose to land ten minutes after the rest, letting the higher tide take them over those shoals. After this assault all but one of the PRINCE HENRY'S Landing-Craft returned, the unlucky one had been mined on or near the beach, the others were hoisted on board while she took onboard 56 wounded that were taken below to her improvised Sick-Bay. After the war she was sold to the Ministry of Transport and renamed EMPIRE PARKESTON for service on the English Channel carrying Troops to and from Britain as part of the British Army of Occupation. She was laid-up in 1961 and scrapped in the following year.

Here are some pics I found, I think I've got them in the right order and the thing that fascinates me is how she changed over the years.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 08/07/2006 : 07:53 Posted - 08/07/2006 : 07:53

Robert, I lost one of your pics whilst editing the width, sorry....... My mate Daniel Meadows did pics at the same place and there was a TV programme about it. Daniel said that they were searched as they left the site. The wage is so bad they were stealing iron bolts. This is only the tip of the iceberg, India is where all the old lead-acid batteries go to die, imagine the heavy matal pollution involved in that. It's the west saving money on recycling at the expense of some of the most badly oppressed people in the world. One firm tried to do things properly in the North East and they are fighting to get permission to build the dry dock in which they can scrap ships like this in an environmentally sound manner. Crazy........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Invernahaille

|

Posted - 08/07/2006 : 15:13 Posted - 08/07/2006 : 15:13

Spot on Stan.

The pay in Alang for those guys was about $1.50 a day. When you consider that the whole operation buys the ships for about $500 million a year, and they sell the scrap and parts for about $700 million a year, labour cost are about $23 million a year. The guys at the top dont want too many questions being asked.

|

Invernahaille

|

Posted - 08/07/2006 : 15:22 Posted - 08/07/2006 : 15:22

Back to more appetising stuff.

Doing calibrations on A Sulzer RD8 This was a particularly hot job. I was taking about twenty salt tablets a day at this time.

(Robert, I've lost a pic again whilst editing the width of the text.)

Cleaning the scavenge ports. This was normally done through the scavenge feeds, but it was necessary to replace the insert gasket seal. So it was done from inside the cylinder.

|

TOM PHILLIPS

|

Posted - 08/07/2006 : 16:07 Posted - 08/07/2006 : 16:07

The sheet steel they are carrying as been cut for rerolling,pays more than the scrap value,I've cut lancashire boilers to a certain size to get better money.There's some great pics on this topic but some of the reading matter ties me in knots.

"Work,the curse of the drinking class"  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 09/07/2006 : 06:38 Posted - 09/07/2006 : 06:38

Robert, watch what you are doing when you put text after the pics. The reason the page is going out of shape is that you are getting spaces in at the end of a line of text that are persuading the programme that the line is longer than it is. Make sure that at the end of each line of text you hit the enter key and start a new line before inserting the pic, in other words, get the cursor where you want the top left hand corner of the pic to be. That should cure it. Sorry about losing the pic of the scavenge ports, put a cursor in, insert the pic and hit the enter key until the cursor is where it should be for the text below.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Invernahaille

|

Posted - 09/07/2006 : 13:55 Posted - 09/07/2006 : 13:55

Cleaning the scavenge ports. This is normally done through the scavenge feed, but the cylinder head needed a new gasket. So it was done inside the cylinder. If you look at the crankshaft picture above you can see an excentic cam to the left of the crankshaft. This connecting rod activated a mechanism like a pair of bellows which forced air into the cylinder through the inlet ports.

|