| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

TOM PHILLIPS

|

Posted - 23/04/2007 : 15:27 Posted - 23/04/2007 : 15:27

Stanley if you have a saw like the one pictured ,I think cutting it with an Hacksaw is deffinately "eccentric"...Or foolish...

"Work,the curse of the drinking class"  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 24/04/2007 : 07:23 Posted - 24/04/2007 : 07:23

The Harrison mill cuts a lot straighter than I can even on a good day! I broke one of my slitting saws the other day...... if anyone has one about, up to 8" diameter, let me know. I'm a customer!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 24/04/2007 : 16:53 Posted - 24/04/2007 : 16:53

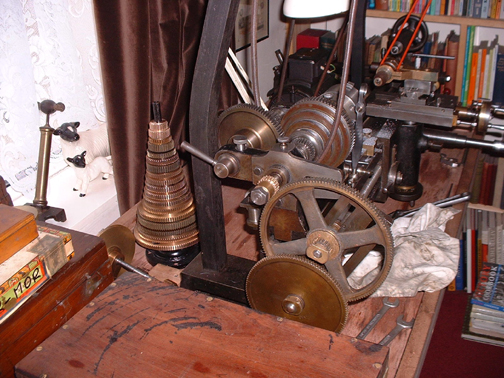

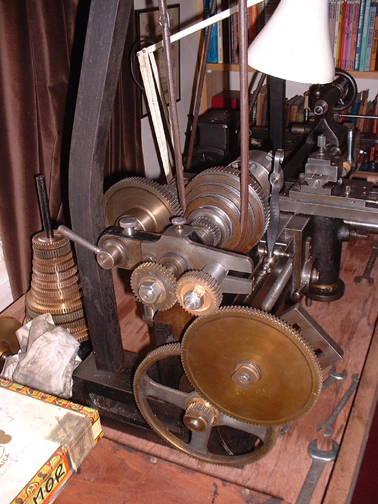

I'm happy to report we now have a set of gears for the 1927 lathe. Only two unusually large ones missing because I ran out of 6" X1/2" blanks. Funnily enough, and call me slow if you want, but I only just realised today the significance of the fact that the leadscrew on the lathe is left hand thread. There must have been an idler stud at one time to insert another gear in the train to reverse the motion so that RH threads could be cut. I suppose I knew this before but hadn't realised how strange the arrangement is. Anyway, I've measured up and I'll make an idler stud for it tomorrow.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

belle

|

Posted - 25/04/2007 : 09:43 Posted - 25/04/2007 : 09:43

As you go along discovering these things, it's almost like you are moving through the brain of the man who made it, understanding his thinking bit by bit. I think it must be very exciting for you, and as always I am dismayed at how many young people today will not have the patience for this kind of thing. We may have the capacity to fly all over the world but to explore the avenues of another mans mind has to be the greatest journey of all.

Life is what you make it |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 25/04/2007 : 17:46 Posted - 25/04/2007 : 17:46

Well done Belle! Exactly right. I know more about Johnny and the way his mind worked than I did when I started on this and no doubt I'll find more when I do the bigger 1950 lathe. It's just another form of archaeology. I found this when I was rebuilding big engines, you found all the short cuts, the mistakes and the crafty fiddles to get something right. I've always said that if you want to understand something, take it to pieces, it even applies to demolishing buildings and chimneys. Fascinates me, who needs travel. I can do time travel in the shed!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/04/2007 : 17:14 Posted - 26/04/2007 : 17:14

I now know why Johnny incorporated a bracket in the back mount of the mandrel. Apart from being handy for the tangential gear it is just right for a stud to carry and idler gear to reverse the motion to the left hand leadscrew. I've found a friendly sparks and the next job is the get the reversing switch wired up properly.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 27/04/2007 : 06:47 Posted - 27/04/2007 : 06:47

Some of you might wonder why I want to reverse the motor.... A geared screwcutting lathe is a very versatile machine because you can dut literally any thread with them, if you're short of a gear to make up the train you just make another the right size. Problem is that without a lot of chalk marks on gears etc. you have a problem when picking up the register after a cut. The easiest way round this is to leave the saddle in gear until the thread is finished. The easiest way to get back to the beginning of the cut is to simply reverse the mandrel with the cutting tool drawn back. A common way of doing this was to fit a small handwheel to the far end of the leadscrew and I am considering that as there is provision for one. However, I can make the motor reversible..... I am torn and think in the end I'll opt for the handwheel. There is another use for it, if the gear train is diconnected you can use the lead screw handwheel for longitudinal feed on the cut. Decisions, decisions......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/04/2007 : 07:14 Posted - 29/04/2007 : 07:14

Funny how the Gods turn round and bite your bum every now and again just to remind you that you don't know everything..... I decided to have a nice brass hanwheel for reversing while screwcutting and started to make it. Then I realised that I had an empty skip parked outside the house and shifeted operations to dismantling my wet dark room which I will never use again. This led to me swapping the modern Anglepoise lamp I have on the sideboard to an older model the same as the one Johnny had which I had been using over the wet bench in the darkroom. While I was on with the sparks I changed the Dewhurst reversing switch for a simple 30 amp on/off switch, smaller and tidier. I fitted it all up, checked my wiring and switched on.... dead short. Of course I assumed it was my fault and checked all the switch wiring. All OK so I tried again, dead short again. In the end I found that it was in the motor, nothing to do with my switches. I've got it in pieces on the bench and I think it's a fault in the centrifugal switch. Nothing to do with my wiring. These switches are tricky little beasts so I shall look forward to a fiddling and frustrating job once I have walked Jack and got myself in gear..... Not happy, but there you are, if you insist on using antique motors you pay a price...... If I can't bottom it I shall call in the professionals, Delta at Nelson and pay out good money.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/04/2007 : 06:23 Posted - 30/04/2007 : 06:23

Every picture tells a story. I investigated the short on the Horace Green motor that drives the 1927 lathe and as I suspected, the fault was in the centrifugal switch, tricky little beasts with lots of tiny leaf springs and contacts. I sorted that out but got a surprise, the new bearing I put in about 4 weeks ago was absolutely shot. Don’t know why but I shall put two new ones in. At least I know now that it will be perfect. I've made the handle for the end of the lead screw and fitted it, useful addition, I reckon Johnny would approve. Now to source two new bearings..... I suspect the reason why the bearing failed was that I didn't use shielded races and a bit of metal has got in. The new ones will definitley have shields!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/05/2007 : 06:53 Posted - 01/05/2007 : 06:53

The bearings are ordered and could get here today. I've decided that when the motor is back on I am going to declare the 1927 lathe refurb finished, tidy up and move on to the 1950 lathe. I am going to use the Horace Green 1hp motor for that, another motor that Johnny bought and I think especially for that lathe. I won't use the full overhead gear because I have a lovely little overhead drive with a clutch in it and powered by its own 1/4hp motor. A tidy solution to the problem. All I will need is a countershaft to get the motor speed down to the right value for the cluster pulley that matches the mandrel pulleys. Lots to do but when I have finished I'll have two of the most efficient OT lathes in the world...... Nice! Big question is, will I start OT? I doubt it, not as an exercise in itself. I'd rather use the facilities to make things that work like repairing old machines and making steam engines, I have enough castings to last me for 30 years.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/05/2007 : 13:05 Posted - 01/05/2007 : 13:05

I'm happy to report that the bearings arrived this morning and the motor is back on the 1927 lathe and running like a sewing machine. I've declared the job finished.

Straight on to the next job.... Here's a big dirty lump for you. It's the one horse single phase Horace Green motor that Johnny bought in 1950, almost certainly for the 1950 lathe. Anyway, that's what it's going to be used for. It's a runner and could actually be used just as it is but after 57 years I reckon it deserves a good clean out and new bearings, I have them in stock ready for it. There is no centrifugal switch in this motor, it runs with both windings in phase all the time. Not sure how this works as yet, I think I might have to call on Gigglepants for a bit of help. So, first job is to make some room round the 1950 lathe and come to some decisions as to where I mount the drive. Look at the size of the motor, a modern motor this size would be 10hp or more. Some meat in it, no wonder they went out of business, people don't appreciate quality like this any more, it's cost they're looking at. I wonder how many modern motors will be looking at a refurb in 60 years?

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 03/05/2007 : 15:59 Posted - 03/05/2007 : 15:59

Well, we've made a start! The first job was to rearrange my assets and get some room under the lathe, then a cleanup and a coat of floor paint. It's a lot easier to work if things are clean. A good thick coat of floor paint can hide a multitude of sins. There's enough room behind the bed at the tailstock end to mount the Horace Green motor on the floor, take a drive up the back to a countershaft mounted on the wall and thus get a drive to the mandrel. I shall have to take the shelves down and put them back up after the countershaft is sorted out. I shan't need any big pulleys on the first motion, the motor does 1450rpm and I'll aim to have the countershaft running at about 350rpm, without working it all out I reckon this will give something over 1000rpm for the top spindle speed. Of course I'll check this. Funnily enough, once the countershaft is mounted I don't think there'll be a lot to do to get running, the lathe is in better nick overall than the 1927 was, it has a massive set of gears and the tangential dividing is already built into the headstock. Enoughg lifting for one day, I've taken a couple of the red pills and will now take it easy!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 04/05/2007 : 10:08 Posted - 04/05/2007 : 10:08

I have to report a set-back..... The HG motor on the 1927 lathe, which was running like a sewing machine, has shorted again. I'm going to have to rethink using it. When it shorts it goes through the bearing and blows the track, it's cost me £40 in bearings to date and that would buy a new motor. Sad, I'll have one more crack at it but if I can't get it to work we use a new one.... Ahh well, at least I tried.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 04/05/2007 : 14:52 Posted - 04/05/2007 : 14:52

I don’t like things hanging over me….. I bit the bullet this morning and of course am now feeling as though I should be guilty but I’m not. I talked to a nice man at Delta Electrics in Nelson and he is going to bring me a new ½ hp motor (£90) and he’ll take the Horace Green motor away and do me a free appraisal. If repair doesn’t mean a rewind I shall have it properly repaired by people who know something about what they are doing. This way, at the very least I get a working lathe with a reliable motor and for a few quid more will have what I originally wanted, the Horace Green motor running properly. I shall feel no pain in having a spare motor about my person. I can’t afford the money of course but then it’s only what I would have paid for the White Shed outside the gate doing nothing for four weeks. So, in a few days…… and I have the whole disappointment of the motor blowing up in my face off my back. Good result.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 05/05/2007 : 06:44 Posted - 05/05/2007 : 06:44

When they bring the new motor I'm going to have them take the Horace Green 1hp as well and check it over, fit a capacitor and give me a wiring diagram! I did some cleaning up on the 1950 lathe yesterday. I'll do a picture for you all so you can get to know it properly.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |