| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 17/03/2007 : 03:52 Posted - 17/03/2007 : 03:52

Not a lot done yesterday as they were sand-blasting the back of the house. All I have to do now is wipe everything down in the shed, what a mess, that dust gets everywhere. As for the mystery object. It's a tool-holder for mounting on a face plate for fly-cutting a surface mounted on the saddle of the lathe. If you look carefully there is a hole drilled in the face with a set screw through the side. This would take a round tool. The tee-slot could carry any other sort of tool-holder purpose-made for whatever you wanted to do like cutting a big radius on a casting laid down on the saddle. Lots of possibilities. The clever thing about it is the feed-screw with the star wheel on the end. You fitted a peg to strike it once every revolution and it put a quarter of a turn on the feed. Very common before milling machines and I can think of jobs where it would still be useful. Newton used to use fly-cutters all the time, he said they were far better than milling cutters and of course you can do quite large plane surfaces at one pass. I think I'll clean it up, it deserves a bit of TLC. No name on it, I'll bet it's a hell of an age.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Another

Traycle Mine Overseer

6250 Posts

|

|

Posted - 17/03/2007 : 05:49 Posted - 17/03/2007 : 05:49

Comrade, would Johnny have invented/devised this tool holder himself or just developed the idea from elsewhere? Nolic

" I'm a self made man who worships his creator"   |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 17/03/2007 : 07:54 Posted - 17/03/2007 : 07:54

Comrade, I doubt it, not even sure it came from Johnny. These fly cutter holders were a commercial item in the days before milling machines became common. A very useful bit of kit even now but they have sunk out of sight like many other good ideas. That's why it is always a good idea to trawl the old manuals and catalogues.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 19/03/2007 : 07:43 Posted - 19/03/2007 : 07:43

I just thought I'd let you know.... I haven't had an accident in the shed, just had the worst stiff neck in the world and It made any movement painful. It's improving, watch this space.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 25/03/2007 : 07:58 Posted - 25/03/2007 : 07:58

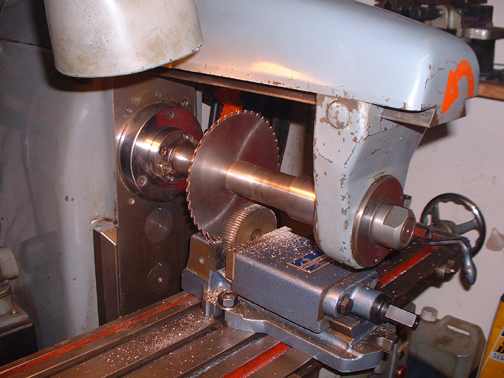

Back on the job. Stiff neck gone and dust from sand-blasting cleared up. Tip, seal all door and window joints with duct tape on the inside as well as the outside, saves a lot of muck. All the old gears are bushed, staked and with the lathe, next job was to find some non-ferocious blanks. I had a redundant gear wheel thick enough to split....

I have a fancy to make a 127 tooth metric conversion wheel so I thought I'd clean up thei old feed valve blank.

Here's the result of an hour's machining, now I need to search for more blanks....

Onward and upwards........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

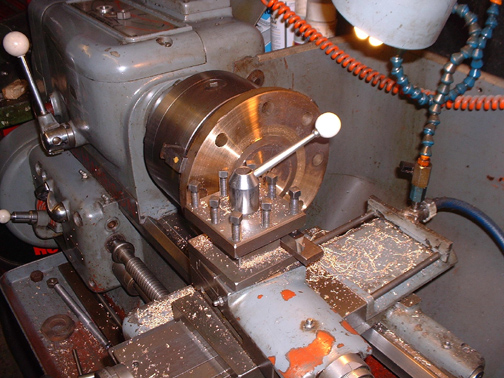

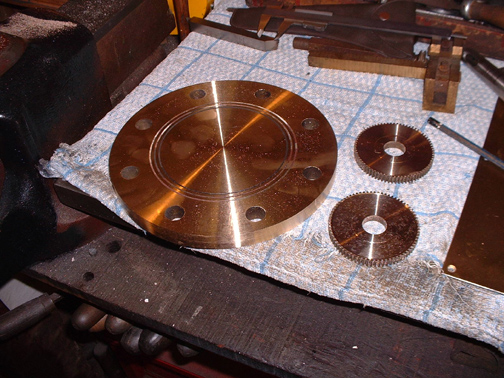

Posted - 25/03/2007 : 17:24 Posted - 25/03/2007 : 17:24

The blank search was productive....

A bit of swarf later.....

The moral of this picture story is never pass a piece of non-ferocious metal without attempting possession!

So, I have some useful lumps for gear blanks. I decided to have a reckon up of what gears I wanted to make and work out the blank sizes I needed. There are 17 gears needed from 20 teeth to 127 in order to make a full set of fives plus the odd sizes in sixes I already have. I shall never use them but I want the lathe to be complete when I finish the refurb. So I sat down to calculate all the blank sizes. I have always assumed that the gear pitch was 6tpi but had noticed when making gears for the lathe that the geaqrs, whilst they ran OK, weren't spot on. I decided to do a bit of checking. Number of teeth + 2 divided by the pitch and divided again by Pi gives the blank diameter. I used this formula but worked it backwards from the OD of the existing gears. I got a big surprise because the pitch was 6.35tpi. As you can guess I did several double takes and went back and measured everything up again. Same result. I hope I haven't missed anything obvious and I have no explanation of why they are this strange pitch. All I know is that all my calculations give the same result. Of course, the pitch doesn't really matter as long as the gears mesh well and are the right number for each wheel. I have one blank wich has finished up at 4" and according to my figures this will do nicely for a 75tpi wheel which according to me needs a 3.86" blank so before I do anything else I shall cut this gear and see how it works out. I shall report further when I've tried this.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/03/2007 : 03:41 Posted - 26/03/2007 : 03:41

I'll bet someone out there was laughing at me and waiting to see when the penny would drop. The dreaded phrase 'metric' had crossed my mind while I was struggling with me blank sizes but being a sensible man I rejected it. Later I did a bit of a sum..... 6.35 teeth to an inch is 6.35 to 25.4mm. Divide one into tother and you get 4. I was right in my Imperial calculation but the teeth have been made metric, 4mm pitch. Looking at the finish on the original wheels they are old and have seen much polishing. I'll bet Johnny came across some change wheels and modified them for his lathe. Being metric, it wouldn't surprise me if they aren't Holtzapfel gears. Does anyone know what pitch they used? I'll bet a pound it was 4mm. At some time he came across some other gears the same pitch but never got round to modifying them for the 1927 lathe, these are the ones I have just done which are in sixes and not fives.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

belle

|

Posted - 26/03/2007 : 09:06 Posted - 26/03/2007 : 09:06

Just called by to see what your up to, don't understand a word of it but keep the pics of shiny machinery coming and I'll be happy.Sorry to hear you had a stiff neck, and the sandblasting mess, hope all is back to normal now!

Life is what you make it |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/03/2007 : 11:34 Posted - 26/03/2007 : 11:34

Not really Belle, am in the middle of both doors off and replaced and roof ripped off the workshop..... Onwards and upwards!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

belle

|

Posted - 27/03/2007 : 09:48 Posted - 27/03/2007 : 09:48

I hope your builders are amusing, we once had a house completely renovated, and the only thing that got me throught the 6 months of dust and debris, was the hilarious stories our builders used ot tell. especially if they didn't turn up. There excuses were poetic and you always felt somehow rewarded!

Life is what you make it |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 27/03/2007 : 16:34 Posted - 27/03/2007 : 16:34

They've done well today, I now have a new roof on the shed!

The masons have walled in the spar ends and are waiting for the concrete copings to arrive. I've spent the day cleaning up....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Invernahaille

|

Posted - 28/03/2007 : 03:20 Posted - 28/03/2007 : 03:20

Talking about excuses for being late. I one worked with a chap who lived in a large caravan on a farm, and it was midwinter. He came into work about two hours late. When asked why he was late he told the following story.

I woke up this morning to the sound of the farmer who owns the farm I live on. He told me that a cow had fallen into a water trough (apparently this was an old bath with the plughole sealed off) overnight and the water had frozen with the cow in it, its legs in the air. We decided to apply some heat to the underside of the trough to thaw out the ice so we could pull the cow out of the trough. When we had done this we attempted to pull the cow out of the trough. Unfortunately, when we pulled the cow over the trough was still attached to the cows back. The cow on standing up, was mortified to find that it had suddenly grown an armoured shell, so, panicstricken it went speeding down the field and disappeared from view. It took us all of an hour to recapture the cow and remove the trough from its back. Thats why I am late.

Our boss just turned round and said, "that story is so far fetched it has to be true, and I accept your reason for being late".

I can just picture in my minds eye, these two guys chasing a cow with a steel bath on it's back down a field.

Edited by - Invernahaille on 28 March 2007 03:33:33

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/03/2007 : 18:02 Posted - 29/03/2007 : 18:02

The bearings for the two old Horace Green motors arrived today so I thought I'd put the new ones in the 1/3hp that's driving the 1927 lathe. In the middle of doing that job the contractors decided to fit a new window in the shed..... Then when I got the motor together I found the switch that's operated by the centrifugal weights to switch from starting mode to run wasn't working. I pulled the whole thing to bits and rebuilt the switch, what a lousy job! Anyway, virtue has triumphed, the motor has lost its bearing grumble but gained a faint whirring noise from the switch. I'm not taking it to bits again!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/03/2007 : 06:32 Posted - 30/03/2007 : 06:32

While I was doing the motor it was raining heavily and the contractors decided to take my window out and replace it with a new one! You wouldn't believe the amount of gear I had to shift...... Big reorganisation needed this morning and they have still to replace all the plaster that dropped! Still, it's all an improvement so we should look on the bright side I suppose....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

belle

|

Posted - 30/03/2007 : 08:44 Posted - 30/03/2007 : 08:44

Careful you don't overdo it, all that shifting heavy machinery...I've got back probs at the mo and it's making me cringe just to think about it.

Inver, the excuse I liked the best from our builders was...the doctor had water pouring out of some pipe or other (all the excuses seemed to involve burst pipes at some stage!) and had called F (the builder) frantically in the morning, could he just come over and have a quick look before he started his work proper. (We were in a very rural environment at the time, and as the doc lived in the same vilage as F it would be unthinkable not to help a neighbour out, even if work was delayed a bit!) The doc had to go off to morning surgery but had left the key under a stone in the garden. "Could we find the b***** stone" said F "we must have turned his whole garden ower and not a key in sight. So there were nothing for it but to go down to the surgery (by this time his second in command K had joined him)and ask the doc where he had put it. Trouble is it were pregnant womans morning, and the receptionist wouldn't let us in to see the doc, told us we had to wait in the queue...so there we were sat down wi all the pregnant women..." K weighed over 20 stone and had a massive beer belly, so i just replied " Your lucky they didn't take him off for a scan!"

Life is what you make it |