| Author |

Topic Topic  |

|

karlelden

|

Posted -

03/01/2007

:

15:06 Posted -

03/01/2007

:

15:06

|

|

I'm just beginning to explore this amazing website, and I put "engine" in your search engine and came up with a BUNCH of hits. I started looking around and decided you people are living in the tall corn compared with us in the US. I have maybe 2 decent larger stationary steam engines to look at in a 200 mile radius. At first glance I thought you were in Hawg Heaven. Looked to me like you had MANY significant preserved engines.

However, I then came upon a picture of the Leigh Mill engine, went to Google to check it out, and came up with this from 1995:

http://www.britarch.ac.uk/ba/ba1/ba1news.html

Down past the news about how skulls used to contain brains is this bit of stuff about the Leigh Mill:

"A rare example of an intact traditional spinning-mill, near Wigan in Greater Manchester, is under threat from a proposal to remove the original mill engine from the building.

The early 20th century, listed Grade II* Leigh Mill, with its surviving engine house and engine, is still used as a factory and now manufactures carpets. The owners, Leigh Spinners Ltd, applied for permission to remove the original engine to create more storage space.

Their application went to public inquiry in November, and John Gummer, the Environment Secretary, is expected to decide the matter later this year.

Speaking at the inquiry on behalf of the CBA, Ron Fitzgerald, an industrial archaeologist, said the importance of the 1923 engine was enhanced by its `extremely rare' survival in its original context. `Out of 238 listed mills in the north, only six engines survive,' he said. "

So, does anyone know if this is true? Are there only 6 surviving mill engines? And does anyone know what finally happened to this engine in the Leigh Mill?

Karl

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 02/10/2007 : 09:19 Posted - 02/10/2007 : 09:19

The mill lodge, if clean, was always a good place for big carp because the warm water encourages them to grow. Trout don't like the water warm..... Only thing that spoiled this was oil getting out in the condenser water.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

frankwilk

|

Posted - 02/10/2007 : 10:42 Posted - 02/10/2007 : 10:42

Hi Stanley

Looking through the information Geoff posted on the history of the Mill,.

I have just e-mailed Mike Rothwell to see if he has a copy of his book on The Historical Heritage of Church & Oswaldtwisle. It never ceases to amaze me how one question can lead on to so much information.

Thanks again

Frank Wilkinson Once Navy Always Navy  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 02/10/2007 : 16:36 Posted - 02/10/2007 : 16:36

It's amazing what is out there if you look for it. I've just been fielding an esoteric question about weaving from America..... Wonderful how they find where you are!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

A.J. Richer

Werebeagle

24 Posts

|

|

Posted - 01/11/2007 : 16:27 Posted - 01/11/2007 : 16:27

Yes, wonderful how we find you...

On the preserved engines front, they do exist over here as well - textile mill engines were not truly thick on the ground but do exist - New England was the home of textile manufacture (along with machinery manufacture and just about everything else) up till the 1960s. My parents were at one time or another textile workers along with other prefessions.

There is a preserved mill engine no more than a few blocks from my home in Chelmsford, MA. It's a simgle-cylinder simple engine with Corliss valves - unfortunately not in steam but in great condition. The mill building it's in was converted to mixed residential and business use, and as far as I have been told the preservation of the engine was part and parcel of planning permission for the buildings.

Next I can get by there with my camera I'll catch a shot or three - i would love to hear Stanley's impressions of it.

Al Richer

|

softsuvner

|

Posted - 01/11/2007 : 20:12 Posted - 01/11/2007 : 20:12

Al

A number of us will be interested to see them. Over here, we forget sometimes that the States was the home of George Corliss who had such an influence on latter day textile mill (and other) stationary engines. It is not generally realised that steam lasted as long in the States as over here. If you haven't already found it, try this link to a website that tries to collect stationary steam links from all over the world including the US.

http://homepage.ntlworld.com/fcrammond/GAM.htm

If the link doesn't work put Fred Crammond/steam engines/uk in your search engine.

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 02/11/2007 : 06:00 Posted - 02/11/2007 : 06:00

Al, have a look at Steam Joe.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 11/11/2007 : 15:40 Posted - 11/11/2007 : 15:40

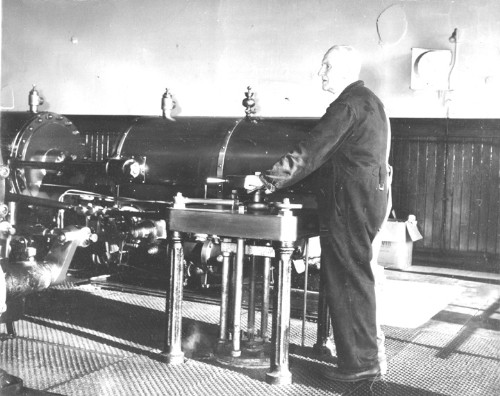

Rossie sent me this pic of Walter Fawcett, engineer at the controls of the engine at Perseverance Mill, Padiham.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 11/11/2007 : 16:09 Posted - 11/11/2007 : 16:09

What a super picture. Can't find any reference at the moment, but the engine has the look of J and E Woods about it. This is a man who is in control!

Malcolm

|

softsuvner

|

Posted - 11/11/2007 : 23:36 Posted - 11/11/2007 : 23:36

I take that back!

She is a late Burnley Ironworks 1200 h.p. triple. Good photo though.

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 12/11/2007 : 05:26 Posted - 12/11/2007 : 05:26

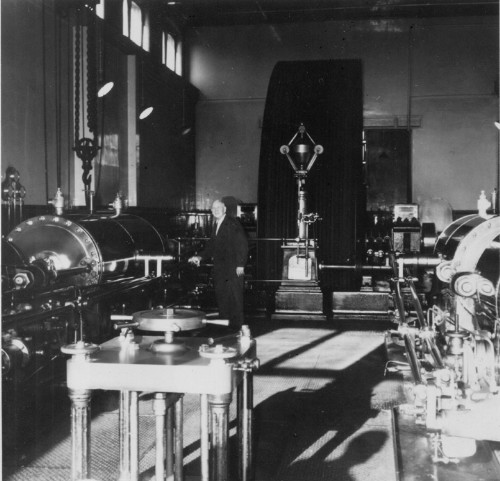

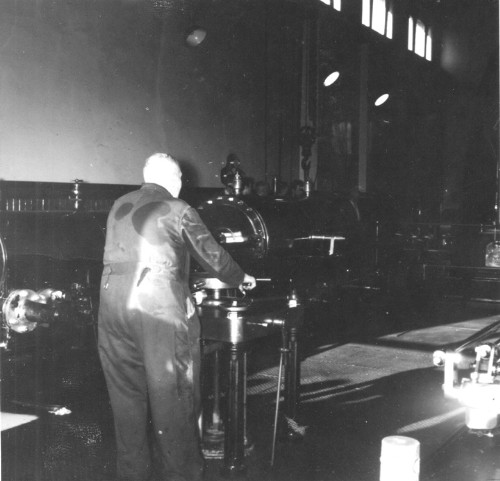

Rossie has sent some more pics.....

Walter Fawcett in Perseverance engine house. About 1950.

Walter stopping the Perseverance engine. Again, 1950s.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 20/11/2007 : 06:14 Posted - 20/11/2007 : 06:14

I got mail from Walter Brunner in Switzerland this morning. Any better Ideas?

Good evening Stanley, I am just ready to machine the key ways on the crank shaft for the cranks on my Corliss Cross Compound engine, when I started thinking about the positioning of the cranks. I am inclined to think, that maybe the crank on the HP side ought to lead in the direction of turning followed by the crank on the LP side offset by 90º. Is my assumption correct? By the way congratulation on the new set up of the web page. Everything works fine, just super. Kind regards Walter Walter, All the cross compounds I have seen have the LP crank leading by 90 degrees if they have been quartered. I have talked to Newton about this and he never had an explanation. My own opinion is that the engine makers preferred to have the LP pulling on the shaft after the push of the first HP stroke. If you think about it, if the HP was leading the first two strokes would be pushing the shaft the same way. I can only think that they wanted to squeeze the oil in the bearing both ways in the first two strokes to make sure that they had good oil distribution. This is my own idea and I can't really see a big advantage, I have never heard anyone offer any explanation. Newton did once tell me about an engine that was quartered using a strange angle, I've forgotten which it was and he said it was a mistake. By the way, Tandems were usually set with the left hand engine leading. Point is, do you trust my advice and explanation? The new dedicated server is costing us £850 a year....... But it's worth it. Best, S.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 20/11/2007 : 11:18 Posted - 20/11/2007 : 11:18

Stanley

The oil distribution theory sounds as good as any to me. In the early days there seems to have been a huge reluctance to produce a horizontal stationary engine at all. There was always a fear of excess wear at the bottom of the cylinder. What is normally claimed to be the oldest surviving horizontal engine: the 1833 single designed by Stephenson for the Swannington incline in Leicestershire has a huge and rigid tailslide. Of course Newton had some interesting things to say about vertical offsets on piston rods in his memoirs.

One suspects that once someone had tried a compund and found that the 90 degree quartering didn't produce significant wear problems, everybody else followed suit.

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 21/11/2007 : 06:45 Posted - 21/11/2007 : 06:45

Malcolm, once they realised that the more even turning motion produced by quartering meant more and better production from speed-sensitive textile machinery they embraced it. See Newtons comments in the LTP about quartering the engine at Broughton Road Shed in Skipton. The engine at Ellenroad didn't have tail rods but there is a massive support bearing between the HP and LP cylinders. Queen street didn't have either and the HP cylinder was very worn in the bottom apart from the grooving caused by the broken piston rings. Personally, I think it's common sense that a long piston rod will sag if unsupported and Newton was quite clear on the fact that the engine makers recognised this and put an offset in the rods so that the effect was the rod was straight. When Bancroft was first started and run it soon became apparent that the LP piston was dragging on the bottom of the bore even though it had a tail rod. They rotated the piston rod through 180 degrees and re-keyed it. I reckon they fitted the rod the wrong way up. Funnily enough that cotter in the LP cross head always gave trouble thereafter and it was me that found the reason for the thump and cured it with a new cotter. I have the old one in the shed and the wear is quite clear on the cotter, they must not have altered the angle on the slot in the rod enough to cope with the reversal. Interesting to note that ovality was still a problem on vertical engines but this was due to the angularity in the con rod as the shaft rotated. This wasn't a problem on big horizontals because the cross head and the bearing surfaces could be made much bigger and were well on top of their job, especially when you think that they were non-reversing and only had to cope with one set of forces, always downwards in an engine running over. Space constraints on verticals meant that cross head guides were often under far more pressure and eventually failed to hold the piston rod in a constant plane.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

oldiron

New Member

9 Posts

|

|

Posted - 28/11/2007 : 04:08 Posted - 28/11/2007 : 04:08

Here's a tandem compound Corliss valve mill engine that's now in Canada. Restored except for a cracked piston ring (currently removed). Engine is in the Museum of Making, near Calgary, Alberta. Came from Sowerby Bridge originally. Now in the company of quite a number of 19th C machine tools.

|

oldiron

New Member

9 Posts

|

|

Posted - 28/11/2007 : 04:22 Posted - 28/11/2007 : 04:22

Sorry, heres a better picture.

|