| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/08/2007 : 17:40 Posted - 28/08/2007 : 17:40

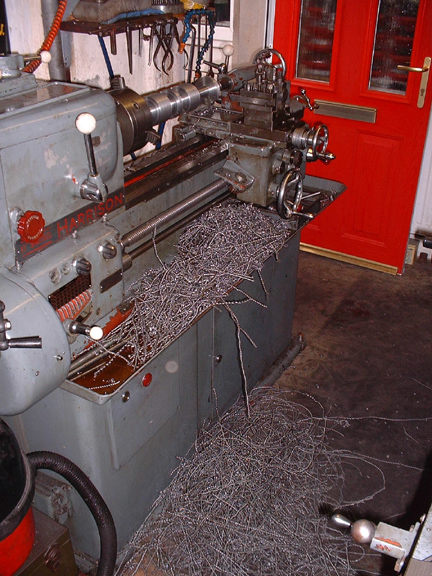

I told you there would be swarf! 4 hours honest endeavour and this is the third heap.

Here's where it came from. This billet is shrinking in weight.

I knocked off at 4:30, I reckon I've done enough for a day. I've chopped out most of the LP journal and started on the HP. If you're wondering where the centre section for the feed pump eccentric went, I decided I had enough on my plate. I can always fit a split eccentric later. My aim at the moment is to fet on with the main job, three steam engines. Time for finessing later.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/08/2007 : 18:41 Posted - 29/08/2007 : 18:41

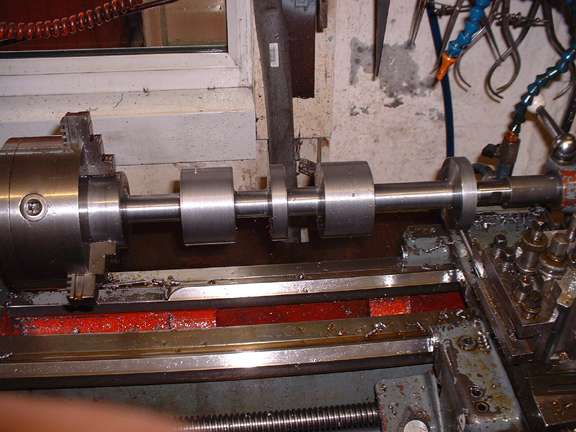

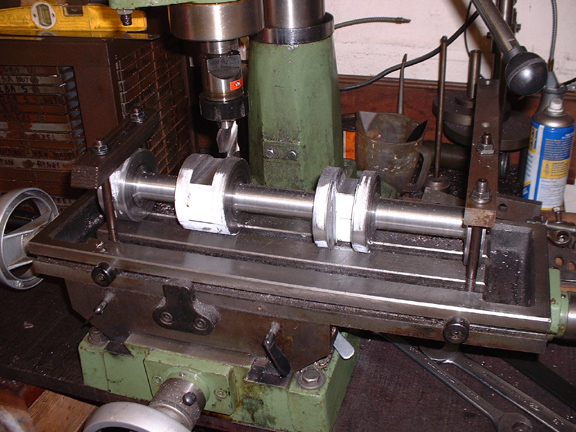

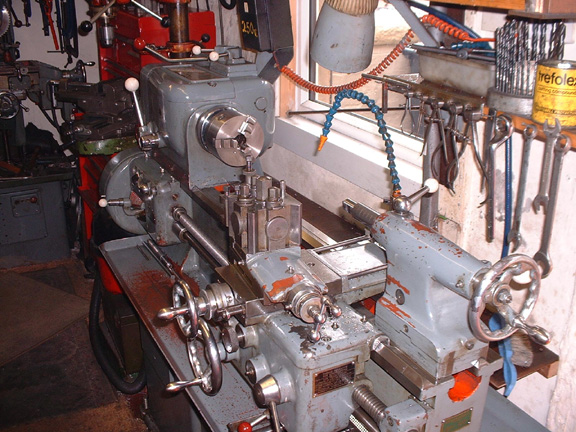

It took all morning to finish milling the leat out of the crank journals and by dinnertime we were set up and ready for the off.

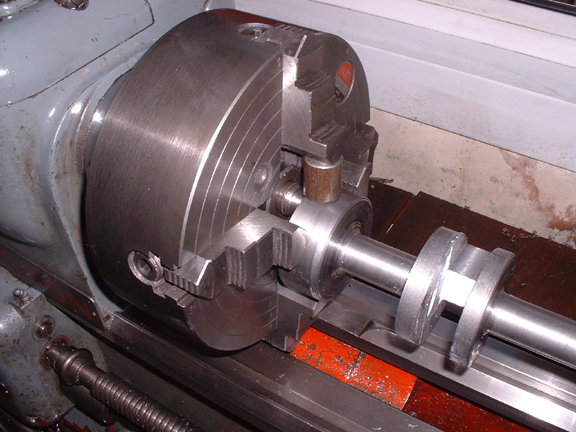

I've included this close-up of the chuck to show how the centre is set up. The purists would say that the ahft should be turned with a catch plate between centres. If you look carefully you'll see the nose of the dead centre poking out of the centre of the four jaw. It's dead easy to mount the shaft between centres and then progressively tighten the chuck jaws until you have the most positive catch plate in the world. No chance of any back lash and rock solid. If you have a dig in, this will save you!

I cannot tell a lie, I went into overtime and finished at 6pm. There was no way I was going to leve the journals when I was so close to finishing them! Tomorrow we go bak to the three jaw SC and the yellow dot and finish the shaft. I'm going to leave this shaft at 3/4 right the way through. It looked stubby on the single engines but I think it makes sense on the compound.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 29/08/2007 : 23:16 Posted - 29/08/2007 : 23:16

Stanley

Using the 4 jaw and centre with a packing piece on the 4 th jaw, instead of face plate with a dodgy old driver clamped on the workpiece, is another trick that doesn't appear in my ediiton of "lathework for amateurs". Like it!

Malcolm

|

pluggy

|

Posted - 29/08/2007 : 23:34 Posted - 29/08/2007 : 23:34

3 days done in 2, justifies a late finish I think.

quote:

Stanley wrote:

35lbs, I'll weigh it again when I've finished. Well spotted Malcolm, I always have a bottle of whisky for ready-use ammunition. I have a swig of codliver oil and a sip of whisky (or in this case whiskey) every morning just before the first dog walk. Keeps me lubricated. The JD is almost empty, Highland Park next I think. Looking forward to the two throw...... Three days?

Need computer work ?

"http://www.stsr.co.uk"

Pluggy's Household Monitor  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/08/2007 : 07:00 Posted - 30/08/2007 : 07:00

Pluggy, the reason for the packing piece is that because of the offset due to the workpiece being eccentric is that the jaw hits the centre before it grabs hold. The centre hole is only 1/2" from the edge of the workpiece. I've never seen anyone else do this but it's so sensible I'm sure someone has done it. Nothing new under the sun. I've seen some really dodgy methods for attaching the driver and bits of advice like tying the catch plate pin to the driver to keep it in contact. On an interrupted cut this is a nightmare especially a big one like this. Milling the meat out before starting is a good thing, Newton was right. I shall never do one any other way. It's not fast but it gets rid of all those hours of jagging in at each cut. One thing that did happen yesterday was that I started to get chatter and eventually realised that alright, I had three inches of parting tool stuck out of the toolholder, but that wasn't the reason. I hadn't checked the cutter for centre height and after all this turning it had dropped a bit. A quick check and re-adjust and we were back to normal. If anyone else is trying this, you need a perfectly sharpened cutter, ten minutes spent on getting it sharp and a good rake on it is time well spent. I always use a fine stone to give it a rub by hand after grinding. Newton never did this but he said that Johnny always polished the cutter. I reckon that this goes back to his days on a treadle lathe, you'd soon learn what was sharp and what wasn't. Again, for anyone who is interested, all this turning has been done at the highest speed in back gear, 119 revs a minute and a fairly fast traverse for muck shifting. Down to the finest traverse speed you have for the final cut. By the time you are getting down to the centre on the cuts on the proper centre you can get away with 70 thou a cut if your setup and sharpening are right. By the way, my mate gave me a nice piece of steel, it cut beautifully. So, a nice day today, plain turning and a bit of fitting. My mind id working ahead to the next job.... I shall make the con rods next, then the piston rods and cross heads, I'll leave the piston rods over length and finish them off when I make the pistons. I shall leave that stage until I have done all the studding and fitting at the top end and before I do that I need to do the valves and steam ways...... It pays to think in fronts a bit.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/08/2007 : 07:03 Posted - 30/08/2007 : 07:03

PS, just realised that you've got it wrong Pluggy, three days for finishing and fitting, it will still be about that. Almost finished the Jack Daniels...... Highland Park next I think!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/08/2007 : 07:27 Posted - 30/08/2007 : 07:27

I've just remembered, I had an email yesterday from a bloke in Padiham who wants to build ab 15" gauge tram engine and asking 'if I had any ideas'. I told him to look for an old barring engine off a mill engine because if he built one himself I reckon he's looking at £50,000 in materials and time. I know that sounds a lot but reckon up the tackle and time I'm employing on this lot. The castings alone would cost £1000 an engine for the small 5As. If you go non-standard and have to make the patterns for an engine large enough to drive what he wants it would cost a fortune. To make money out of a single 5A you'd want £3,500 plus all your expenses and depreciation on tackle. £5,000 wouldn't be a daft price and this is only a 2 1/4" X 2". Apart from all that, and I always shy away from self-praise, but how many blokes are there about who could do a none-off steam engine? Thin on the ground I think. I hate to think what it would cost me to go out and equip a workshop fit to do the job, how much change out of £30,000? Newton once told me about a good fitter in Barick who did subbie machining in the little brick shed at the bottom of Park Avenue opposite the Dog. He got a contract to make a fair sized bunch of steam locos at what looked like a fair price. He wasn't far into the job before he chucked it up because he realised that what looked like an attractive price would leave him working at a loss. There's a world of difference between playing about in the shed like I do with tackle I have aquired over the years and setting up to do it commercially. Nobody wants to pay the price. It takes a good man to recognise this. I once went into work at Rochdale welding where we had been working on building a big combustion chamber for weeks, serious lumps of metal, I had to use a five ton travelling crane to get the plates onto the radial drill. This particular morning John came out of the office and told me to cut it all up and scrap it. He had realised that chucking the contract in and taking the loss was cheaper than going on. Big decision but like he said, it was costing him serious money to do it. Pity really, because the only way the client could get it done at that price was to bank a small operator. So, what's the real cost of making an engine like the tram engine the bloke wanted? Thank god I had the castings, most of the material, the shed and its tackle and the experience to have a stab at making four engines. One thing is certain, I'll never do it again, it's a labour of love!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

pluggy

|

Posted - 30/08/2007 : 12:21 Posted - 30/08/2007 : 12:21

Yes it was three days, what threw me is that the post saying it would take 3 days was written early in the morning and that was the first day. I was looking at the dates 27th -29th, 2 days if the posts had been the same end of the day.

Need computer work ?

"http://www.stsr.co.uk"

Pluggy's Household Monitor  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/08/2007 : 17:15 Posted - 30/08/2007 : 17:15

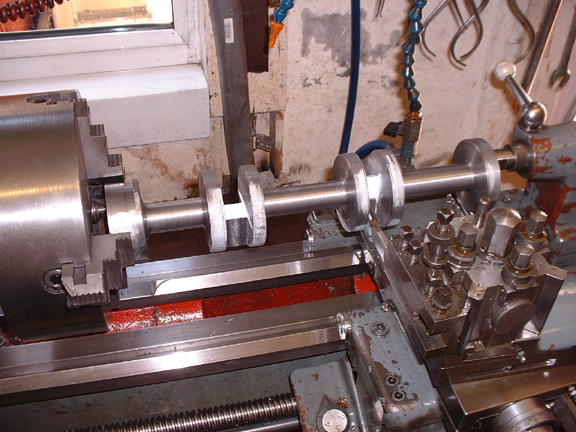

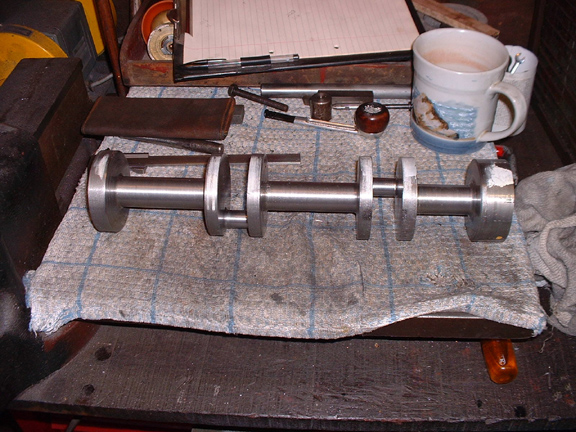

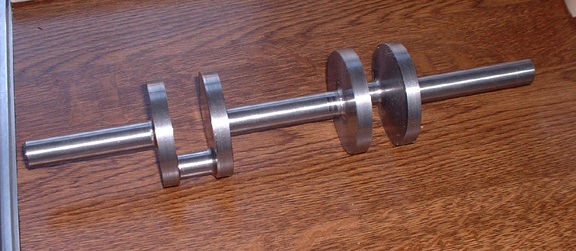

Started at 35lbs, it weighs just over 5lbs now and no length or diameter wasted. I knew it was in there somewhere. I got to this at 16:30 and knocked off. I shall fit it to the engine beds tomorrow, a nice quiet little job..... I ran into a problem turning the last lump off, no matter what I did I was getting chatter. I checked everything, sharpness, tool haight, drilled a new centre hole, thried adifferent centre and then the live centre. The cure in the end was to gramaphone turn it with a sharp point. I think the problem was something to do with harmonics from the gearbox, there wasn't enough weight in the complicated structure to damp it out. I got back to a normal tool when I'd got it down to an inch diameter. I'll bet if I'de been working on a belt-driven lathe I wouldn't have had any problem. Newton always said that shaft and belt driven lathes gave a far better finish. I'll believe him because you get the same effect on Johnny's 1927 lathe, far better finishes from the tool.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 30/08/2007 : 23:10 Posted - 30/08/2007 : 23:10

Stanley

The steam tram era was so short, and so long ago, there has never seemed much interest in miniatures, I can only think of 2 miniature steam trams. One "large" miniature on 2 foot gauge used a converted boiler pump (Mumford I think), I've never seen it, so I haven't a photo. A chap from Oldham called Pritchard made a loco and trailer before the war on, I suspect, about 9" gauge. He used a Stanley or Locomobile steam engine. The engine still exists tucked away in a corner at Crich Museum, I will try and post a photo.

A steam tram would seem attractive because you can tuck the works away behind the sheeting, but like the model Sentinel locos that have ben made using Stuart engines, there is still a heck of a lot of work. Didin't somebody once estimate 3000 plus hours to build a loco from castings? I'd hate to try and cost a one-off.

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 31/08/2007 : 05:39 Posted - 31/08/2007 : 05:39

I've been looking back and I got the castings for the engines out on the 7th of July. Thats roughly 50 days up to now at say six hours a day. So 300 hours up to now. (I'm quite surprised really at the speed I've got on! Must be improving.) Probably about 1/3 of the way through so say 1000 hours for 4 engines. A commercial price with on-costs would be a minimum of £30 an hour so that's £7,500 an engine. Add £1,000 for the castings and materials. No wonder you don't see a lot of them about. In case anyone's thinking this is a bit steep, how much does a plumber charge for an hour? Some garages calculate over £100 an hour for labour. Amazing isn't it when you reckon it up!

As for miniature trams..... I'm not surprised there aren't many about. I mean, they're ugly aren't they! I don't think I was far out with £50,000 as a blue sky figure for the tram engine the bloke was enquiring about. As for the engine factory.... looking forward to a bit of quiet fitting and very glad the difficult turning is over for a bit......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 31/08/2007 : 18:00 Posted - 31/08/2007 : 18:00

Well, you know me.... the first job was a good clean up. Actually I did nothing until this afternoon, I think I had a mild case of PCD (Post Crankshaft Depression), I felt tired and didn't want to do anything. Don't laugh, I have lived with the possibility of having a problem for a week now and I hate crankshafts.

Once I'd cleaned up I had a quite hour or two adjusting bearings and getting the crankshaft in the double engine. Lots of fiddling but in the end we got there. I'd deliberately turned the cshaft a couple opf thou bigger than the bearings so all the adjustment was in the brasses. Turns over nicely and it begins to look like an engine. I haven't cut a keyway in the shaft end, I'll decide on that later. The shaft looks OK left at 3/4" I think.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 31/08/2007 : 23:20 Posted - 31/08/2007 : 23:20

This is the model steam tram that I mentioned before, tucked away at the Crich Tramway Museum. Apparently it was used on a passenger carrying line, but, how you drove it , and where the passengers sat, (inside the trailer?) I don't know. This is the model steam tram that I mentioned before, tucked away at the Crich Tramway Museum. Apparently it was used on a passenger carrying line, but, how you drove it , and where the passengers sat, (inside the trailer?) I don't know.

Steam Trams Ugly? I don't agree, functional certainly. The Kitson engines with arched glazed windows in their sides, always remind me of small self-propelled tin chapels. The vertical- boilered "Wilkinson" patent engines, of which this is a model, had a much more purposeful look. By law, steam tram locos had to "consume" their own smoke, steam, and water, not make a loud noise, and not display any moving parts that could frighten the horses. Hardly surprising that they looked a little boxy ! Thanks to the discovery of the Mitchell and Kenyon films, we can now see them gliding around in the background of Oldham and Halifax, and centre-stage in a scene in the middle of Wigan over a century ago.

It is very sad that of the three and a half surviving engines, none are likely to steam in the future. If you want to see a British steam tram in action, you have to go to New Zealand!

Stanley, I think that you have crankshaft fatigue, a few days off, a trip to Ellenroad, and, perhaps, a nice single malt should do the trick!

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/09/2007 : 06:34 Posted - 01/09/2007 : 06:34

Malcolm, you're a wise man..... I had come to the same conclusion, an old bloke doing too much. I lay in bed last night thinking about con-rods and how I wanted to make them different than th the Stuart way; they use the brass bearing as the body of the con rod end, and decided I was going to make proper marine ends with the bearing inserted. I shall do just what you say, take a couple of days off from serious work. And Ellenroad will be a holiday! Mind you, a bit of light cutter sharpening could be relaxing..... As for trams, you're right, beauty is in the eye of the beholder, I like cranes and they are ugly!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/09/2007 : 09:26 Posted - 01/09/2007 : 09:26

Have decided to write a couple of articles on Horace..... gets me further in front so less hassle in the shed!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

|

|

|

|