| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/01/2007 : 15:22 Posted - 30/01/2007 : 15:22

It's been an upset day today. We had to block the front room fireplace to prevent muck dropping in when they do the stack and the chimney sweep comes on Saturday. So, work on the 1927 lathe has been held up. However, I have found an old British Railways gunmetal flange in me bits and a lump of gunmetal that started life as a riser on a big casting. These will miraculously become a faceplate when the faceplate fairy gets round to it. I cleaned up as well, the Harrison is as clean as it's been for a while and I found the oil gun and gave all the bearings a shot of oil, did the horizontal mill as well. So I thought I'd do one guy maintenance and then I can spend a couple of hours making some more muck! Sheds are wonderful......... Oh, and by the way, they just asked me what colour I wanted my new outside doors, I chose red. They tell me they cost £600 apiece!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

TOM PHILLIPS

|

Posted - 30/01/2007 : 16:05 Posted - 30/01/2007 : 16:05

Stanley ,we once worked at a paper mill in Oldham and we needed some information about something we was doing,we asked a bloke where the engineer was ,he said "you only need the engineer if you want a nut and bolt,ask the fitter if you need an answer"....ared door will look nice Stanley,remember you only get what "they" pay for....

Nice job Kev,see youve got your own personal dinning table.....

"Work,the curse of the drinking class"  |

Big Kev

|

Posted - 30/01/2007 : 17:19 Posted - 30/01/2007 : 17:19

Saves me having to eat with the children.........

Big Kev

It doesn't matter who you vote for, you always end up with the government.  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 31/01/2007 : 07:05 Posted - 31/01/2007 : 07:05

That's about right Tom. A fitter is an engineer who can actually do the job. I've seen engineers who would have difficulty operating a toilet roll holder.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 31/01/2007 : 07:33 Posted - 31/01/2007 : 07:33

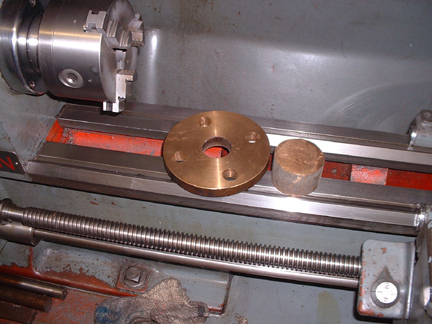

I went back into the shed last night and decided that the offcut of bronze riser was a bit big so I went to rifle me treasures for a smaller piece. While I was in there I found a gunmetal chuck back blank at the bottom of the heap that was exactly right so the old BR flange and the riser went back in the drawer and the backplate casting came out.

Change of chuck to a big 3-jaw with inte4rnal jaws on it and a bit of roughing out....

More muck on me clean lathe. Half an hour and one small mistake later.....

The faceplate is rough finished on the back, bored and threaded 3/4 Whit 10TPI, recessed for the register on the 1927 lathe and ready to be fitted to the nose and finished on the same lathe it will work on. However, I shall change the chuck on the Harrison, mount the faceplate by its spigot and do all the rough turning on that because it's a bigger and more powerful lathe. Then I'll mill the work-holding slots in the faceplate and finish off by taking light cuts on it in the 1927 lathe to bring it to perfect truth. It will change shape slightly over the years as the stresses come out of the casting but all that will be needed is a light cut across the face occasionally. Then it will be used for holding anything that is shaped irregular and cannot be held in a normal chuck.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 31/01/2007 : 07:38 Posted - 31/01/2007 : 07:38

It just struck me that you might be wondering how I came to have the casting. In the days when I was ordering castings regularly for jobs on steam engines etc. I would always keep my eyes open for scrap risers, old flanges or anything that looked useful. If I was getting a chuck back cast I'd order two or three and chuck the spares in the box. Over the years you end up with some very useful lumps which save breaking into the pension fund. This casting is a case in point, it's been sat in the box for about 15 years but has finally found a home.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

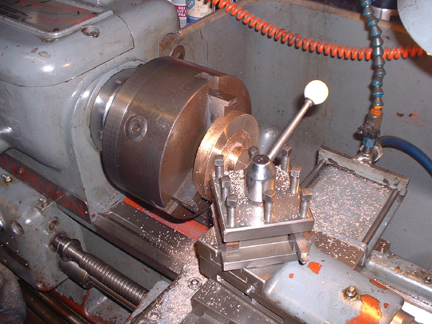

Posted - 31/01/2007 : 17:44 Posted - 31/01/2007 : 17:44

We have a faceplate on the lathe! Now I need a 3 1/2 inch four jaw chuck....... I might even have to buy one! One or two odds and sods to do, like 1/8 inch open ended 5/8 whit spanners for unlocking the mandrel to put it in back gear. Some tidy storage for the tools and odds and sods, make a set of cutters for it and set up a flycutter that can be mounted on the saddle and used with the overhead drive. Wonderfullt satisfying work. If Johnny and Newton are watching I think they'd approve.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 02/02/2007 : 10:53 Posted - 02/02/2007 : 10:53

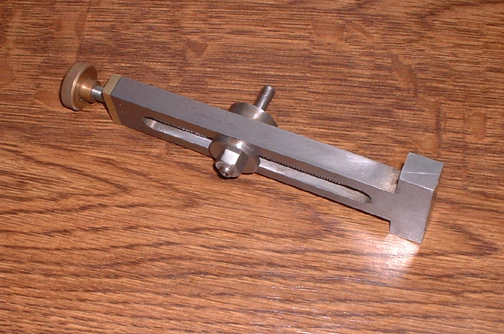

The latest addition to the family, a 5/8 whit spanner with jaws thinned down to 1/8 inch for operating the mandrel clutch for running the lathe in back gear. Gears run very quiet at low speed, on highest speed they just ring a bit but not excessive. Now for a tailstock chuck.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 03/02/2007 : 06:40 Posted - 03/02/2007 : 06:40

The lathe fairy has been busy again, we have a chuck for the tailstock. I had a number 2 morse taper stock with a no. 2 Jacob's taper on it. I ground it down to a no. 1 and we are in business. I also found a tailstock die holder that fits, we are getting a well-equipped little lathe now. What I need is a box to store all the bits in so the ornament looks tidy!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 03/02/2007 : 08:48 Posted - 03/02/2007 : 08:48

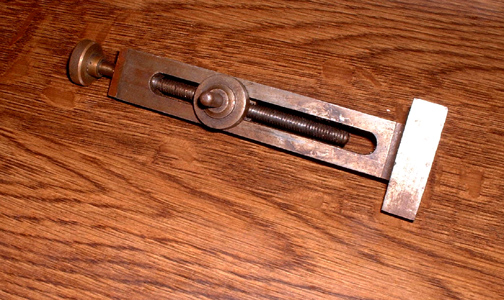

Not the most interesting pic in the world...... However, there is more to this than meets the eye. I am always fascinated by the way my brain works. Time and time again I have noted that there is a section somewhere inside the back of my head that works 24X7 on problems and occasionally pops up with a solution just when you least expect it. As you know, of late I have been spending a lot of time with the 1927 lathe and trying to match up bits of Johnny Pickles' machining career which have been in my drawers for years.

Yesterday, after sorting out a tailstock chuck my mind wandered to the peculiar configuration of the tool holder on the saddle and its relationship to the attachment on the back side of the lathe which holds a profile plate to enable you to cut complicated shapes while turning like handles etc. When I got up this morning I had a thought and went to the bit of apparatus above which had been puzzling me for a while. I got it out, offered it up to the two enigmatic screw holes on the face of the cross slide and Eureka.... a perfect match. This is what is known in the trade as a trammel. It fits on the cross slide and the peg acts as a stop when it hits the profile plate. I shall clean it up, get it fitted and do you another pic when it's in place. You can imagine how satisfying this is for me. It is a good day!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

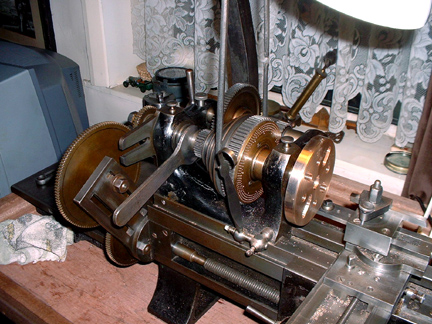

Posted - 03/02/2007 : 17:03 Posted - 03/02/2007 : 17:03

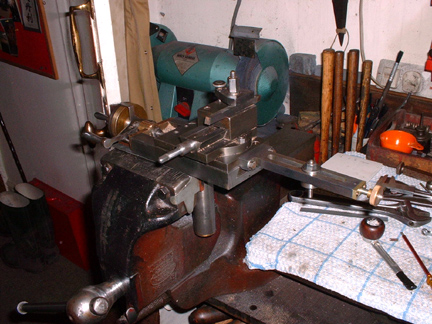

The first job was to take the trammel to bits and clean it all up. Johnny had taken a lot of trouble over the finish on this.

#

I took the cross slide off and gave that a good clean and then fitted the trammel. Biggest job was finding 1/4 whit set screws, I thought for a while I was going to have to make them. All the threads in the holes on the cross slide were cleaned up.

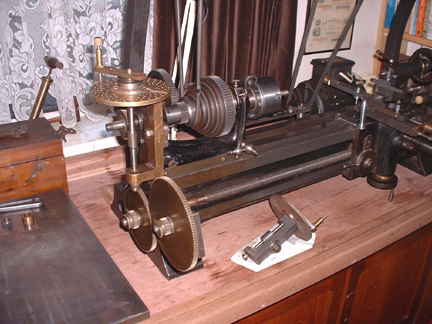

Here's everything set up on the lathe with a dummy work piece in the chuck. I think you can see the peg below the trammel ready to engage with a profile plate (none fitted) which would mount on the attachment at the back of the lathe bed using the square-headed set screws in the top plate. The lenth of thread on the adjustment for the pointer is needed if you were putting a profile on a larger disc shaped workpiece, something like an edge on a base for something. Now I need to make a hardened profile plate and make some posh handles!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 07/02/2007 : 10:48 Posted - 07/02/2007 : 10:48

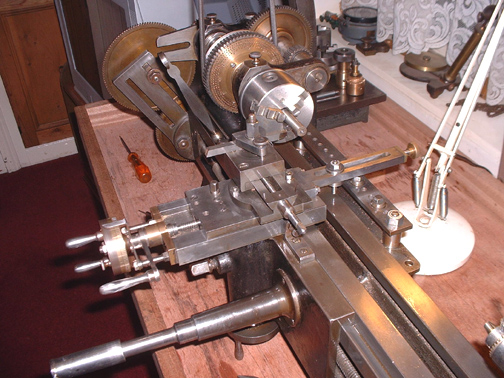

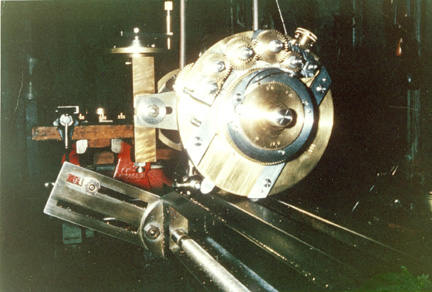

Here's an old slide of the 1927 lathe when Johnny was in his hey day. The chuck is an epycycloidal chuck fitted up with an eliptical chuck as well. Don't even ask me to explain, it's like three dimensional chess! The point o the pic is the gunmetal pillar with the handle on top which looks like an attachment on the chuck but isn't. It's mounted on a pracket in the gear train at the back of the mandrel. This triggered me to dig in the bits again and here's what I found:

Here's the same item mounted on the 1927 lathe after I dug it out of the treasure box. It's half of a tangential dividing head which fits on the back of the mandrel. The half that's missing is a worm wheel to key onto the mandrel. By using this, you can arrange it so that the mandrel can be rotsted step by step through almost any number of divisions for gear-cutting or ornamental turning. I shall have to make a worm wheel for it. I had a further dig and found I have the hob that Johnny made to cut the teeth on the worm wheel. I've never done this before and it will be what they call 'free hobbing' where the cutter turns the workpiece so I'll have to d some studying! There is another worm laid in the tray with a coarser thread but for the same purpose. I haven't quite worked this one out yet. There was another discovery in the treasures, but I'll leave that until I have the worm made...... The more I dig and the more I find for the 1927 lathe the more I realise what a versatile little lathe it was. Johnny was brilliant!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 08/02/2007 : 05:06 Posted - 08/02/2007 : 05:06

Found this last night.... Here's Johnny using the 1927 lathe in his shed behind his home at Federation Street. Notice that the tangential dividing head is in place and the worm wheel on the end of the mandrel. I am convinced I have this wheel somewhere! I never forget something like that but I can't find it anywhere. I shall have another search today.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

marilyn

|

Posted - 08/02/2007 : 05:13 Posted - 08/02/2007 : 05:13

I like all the 'shiny bits' on this page...which is full of wonderful photos....and I am trying very hard to keep my concentration going....

but my eyes keep glazing over and letting me down.....

get your people to phone my people and we will do lunch...MAZ  |

belle

|

Posted - 08/02/2007 : 09:30 Posted - 08/02/2007 : 09:30

Haven't visited this topic for a while, but oh i did enjoy the three pics of the gunmetal being fashioned into a faceplate, that was almost magical....you are an alchemist Stanley!

Life is what you make it |