| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 24/11/2007 : 16:20 Posted - 24/11/2007 : 16:20

I got in the shed today! I was getting quite worried about my motivation. All the valves are finished and ready for fitting. driving nuts all drilled and threaded and valve faces rubbed down on wet and dry on the surface plate to get a surface. Tomorrow I can start packing glands and lacing the first engine up to running order. Then I can move through the others. This is the really nice bit, you feel as though you are getting somewhere when you start putting jointing in the surfaces.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 25/11/2007 : 01:07 Posted - 25/11/2007 : 01:07

This is definately the exciting bit, I'm looking forward to seeing the compound up and running, that will really be more Stanley than Stuart!

Going back to what you said yesterday about poor engineering, Dad always maintains that the worst engineered thing he ever saw, was an American wartime stationery-engine called a Clinton. Made to last about 5 minutes. Most complicated, he claims, was the electro-pneumatic gearbox of an American car called a Cord, which he rebuilt for the manager of a bank in Bushey in the 1950's. Can't be Yankee engineering, he loves his wartime Southbend!

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 25/11/2007 : 06:44 Posted - 25/11/2007 : 06:44

You're right Malcolm. But I have myself firmly under control. There will be no commissioning runs until they are all done but before the tiddly bits. All the other con-rods need shortening but this will be after I've fitted this one up properly. I want to be sure there is room for the gland etc. Today I shall take the cylinder off, fit the valve properly and do the packings then the last build of the cylinder with sealant and stud ends tidied up etc. The nice thing is that it will never come to bits again unless someone uses it seriously and wears it to the point it needs a rebore. There's enough metal in the cylinder to allow for at least one re-bore, no skimping here!

The South Bend lathes, especially the toolroom models with the Norton box are excellent lathes. Have a close look and see how closely Myford followed South Bend practice. Engineers were complaining about US machine standards way back in the days of Whitworth, much of it sour grapes I think. In the early days they skimped a bit on bed strength but they soon learned the lessons. Like everyone else, they had their El Cheapo manufacturers but on the whole it was good stuff. Look at the American accessory makers, think Brown and Sharp et al. Your dad does right to stick to his SB, is he still in the shed?

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 25/11/2007 : 07:01 Posted - 25/11/2007 : 07:01

Lousy pic of a brand new Kirkham version of the Lunkenheimer. (Me old Fuji camera is giving pause for thought.....)

A rare look through the furnace door. If ever you're short of a lubricator give me a shout...... Some old but lots are brand new. Never walk past something like this if you see it lying about.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 25/11/2007 : 07:02 Posted - 25/11/2007 : 07:02

By the way, you're right...... Thats a traction engine governor in the background........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

pluggy

|

Posted - 25/11/2007 : 08:10 Posted - 25/11/2007 : 08:10

Thats where all the non-ferrous bits from ransacked derelict mill engines wind up.........

Need computer work ?

"http://www.stsr.co.uk"

Pluggy's Household Monitor  |

softsuvner

|

Posted - 25/11/2007 : 10:29 Posted - 25/11/2007 : 10:29

Blimey Stanley, you won't be short of lubrication! The "barn" engine boys would snap your arm off for one of them, a couple of sight glasses would pay for a new digi-cam.

As I understand it, the Southbend was the standard wartime unit for US mobile workshops. All the landing craft etc had small self-contained workshops complete with 5 inch Southbend, which is where all the ones over here came from. The design was continued over here as the Boxford. Dad has a Boxford vertical slide on his which bolts straight on.

Dad's arthritis stops him from doing a lot in the workshop, but he still potters bless 'im. Just like when I lived at home, his car stands outside, and his garage functions as a bike workshop for my brother in law ,and the nephew and his mates, so Dad still does a bit of "consultancy" work!

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 25/11/2007 : 13:48 Posted - 25/11/2007 : 13:48

Good, it'll keep him young!

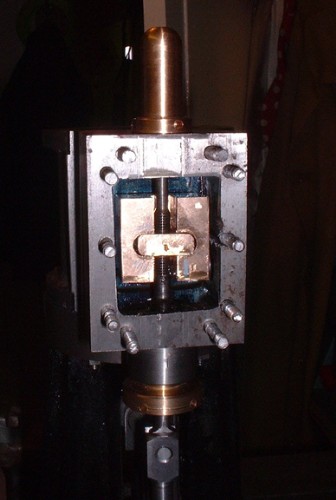

Here's one for the slide valve men. I decided to set the valve properly instead of just getting it somewhere near and fiddling afterwards. First thing to do is have the eccentric loose on the shaft and turn it by hand so you can see what the throw is on the valve. Adjust it with the threaded valve rod until you get it running dead centre, in other words, exactly the same event at each end of the travel. Then st the crankshaft on TDC and turn the eccentric until the top steam valve is just open a crack. Nip the eccentric and chexk it is the same event at BDC. If it looks OK, nip up the fastenings on the eccentric. Bob's your uncle, valve set to give a whisper of compression and open as quickly as possible. If you look very carefully into the gloom you'll see that the valve is just opening at the top. The cshaft is on TDC. Very pleased with the valve, no lost motion at all.

By dinnertime I'd laced it all up with Hermetite seals and the engine is ready to run. Newton used to cheat and pop a chuck on the end of the shaft at this stage for a flywheel and give it a run. I have resisted this. If I had only built one engine I'd have done the same but with three more cylinders to sort out I'd rather concentrate on getting them all to the same stage.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 25/11/2007 : 13:52 Posted - 25/11/2007 : 13:52

PS. Sorry Pluggy, wrong again, most of the lubricators and pumps are brand new, many of them in the original boxes...... One big one made by me as a spare for the Ellenroad engine.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

pluggy

|

Posted - 25/11/2007 : 17:33 Posted - 25/11/2007 : 17:33

Tongue in cheek Stanley, You care too passionately about old mill engines to ransack 'em.

Need computer work ?

"http://www.stsr.co.uk"

Pluggy's Household Monitor  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/11/2007 : 05:31 Posted - 26/11/2007 : 05:31

No, I'm not too sentimental. One of the first things I did at Bancroft was do away with the four lubricators on the bell crank linkage to the air pump. All they did was throw oil all over the place. I just popped a drop of cylinder oil in the holes at starting time and dinnertime. No problem at all. I see the Trust have put oil cups with spring lids back on. No need for them...... I got many of the lubricators from Kirkhams when they closed down, also the CI patterns for various sizes of lubricator bodies.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/11/2007 : 17:53 Posted - 26/11/2007 : 17:53

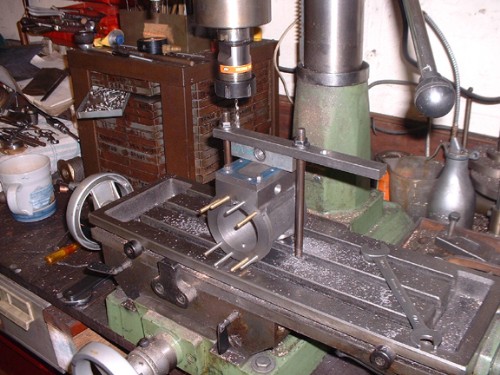

I think the operative phrase is 'next one for shaving'. Small engine number 2 goes in the fitting shop for completion. First thing is to drill the face of the valve block for tapping 2BA. To get a solid setup I had to cover the two centre holes with the holding down tackle so I tapped the ones I had drilled so I could fit the lid with four 2BA set screws and drill the two I had missed. I use the lid as a template because it was the lid that was used as template for the steam chest.

Here's the lid in place and ready to be drilled.

Ready for drilling the last holes.

It's not easy and it isn't quick. Here we are at teatime, all the studs fitted. I fitted them with the steam chest in place and the face between the chest and the cylinder coated with Hermetite. Taking the chest off once all the studs are fitted can do more harm than good because the studs are very closely fitted and you never get all the holes dead in line. Ready for valve fitting but I'm not going to do that until the cylinder is set up with the con-rod connected so I can time the valve and lace it up permanently. By the way, I remembered to bush the tail rod and drill to the exact fit for the valve rod. Con rod shortening is the first job tomorrow.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/11/2007 : 17:59 Posted - 26/11/2007 : 17:59

PS. I don't think I mentioned it but I found out what was wrong with the old Fuji camera..... The flash was set on slow synch so I was getting two exposures, one flash and the other available light. How did I find out? I decided it was time to read the instructions..... I've only had it 5 years. Ah well, when all else fails.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Ringo

Site Administrator

3793 Posts

|

|

Posted - 26/11/2007 : 18:04 Posted - 26/11/2007 : 18:04

You did well to find the instuctions after 5 years.

|

pluggy

|

Posted - 26/11/2007 : 18:43 Posted - 26/11/2007 : 18:43

Caring passionately and sentimental isn't the same in my book. I've read your memoirs about the goings on at Ellen road and meanwhile pulling the plug on another thats past help. Thats what caring is, sentimantal is keeping them for the sake of it.

Changing the things you can and accepting the things you can't and knowing the difference is the sign of a great man.

Need computer work ?

"http://www.stsr.co.uk"

Pluggy's Household Monitor  |