| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 25/01/2007 : 12:24 Posted - 25/01/2007 : 12:24

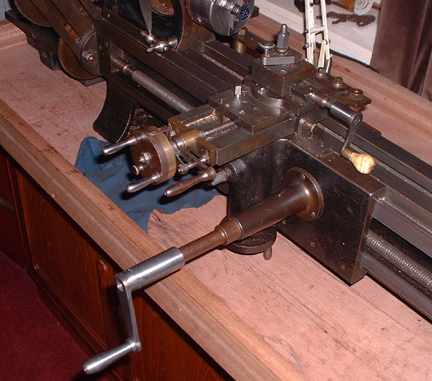

The shaft for the traverse hanle is made. I got the half inch square off a worn out 1/4 inch Whit. socket, saved a lot of filing. I've sunk in in the end of a barrel made to fit the round part of the shaft and now all I have to do is work out how to attach the handle..... I've looked at the one Johnny made for the 1956 lathe but I can't work out how he made it! I suspect my eventual solution will include some welding!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

TOM PHILLIPS

|

Posted - 25/01/2007 : 20:23 Posted - 25/01/2007 : 20:23

Stanley,thanks for the internal square explanation,crystal clear now.Never knew that motors had birrth certificates,ive seen aluminium plaques on motors with the date made and other info,its turning into geneology with motors..

"Work,the curse of the drinking class"  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/01/2007 : 06:29 Posted - 26/01/2007 : 06:29

Tom, Only with old fashioned firms like Horace Green. I have put him in touch with a man who can help him make sure that the archive is preserved. I had to resort to welding with the traverse handle. I am not the best small joint welder in the world, I now have to clean up the mess..... It's not too bad and I think I can disguise my incompetence. Now I need to make a nicely shaped knob for it.........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/01/2007 : 13:04 Posted - 26/01/2007 : 13:04

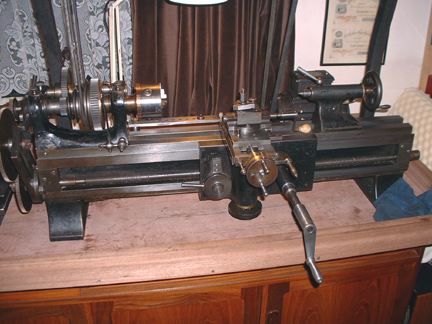

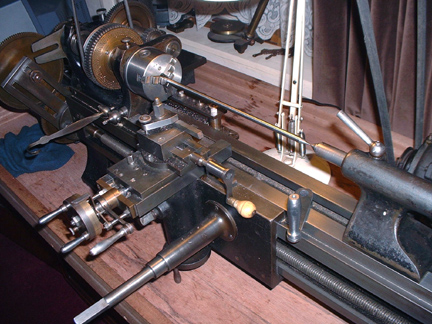

Well, not as beautiful as Johnny's but tidy enough not to cause offence I think. We now have a traverse handle on the lathe. I'm going to have to address the big problem now, the bent mandrel..... Plan'A' is a big rubber hammer to clout the chuck in the opposite direction to the blow that bent it. Daft as it sounds, that could bring it near enough to truth to allow a light skim of the thread on the nose and a re-facing of the back stop to put it back in truth again. Plan 'B' is to take the mandrel out and make a new one but I want to avoid that if possible, it's a serious turning job...... The first thing to do is some serious measuring........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/01/2007 : 18:10 Posted - 26/01/2007 : 18:10

I've had a bit of a clean up all round. You can't get accurate measurements off dirty surfaces. In case anyone is wondering what the plate behind the bed with the holes in it is for, it's a fixture for carrying a profile plate which is used for doing things like turning shaped handles. Tomorrow we attack the mandrel!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/01/2007 : 13:01 Posted - 28/01/2007 : 13:01

Well, what an interesting morning....... I have done most of my checks, just a couple more this aft. to make certain, but I;ve had a bit of a shock! The good news is that the mandrel is dead accurate. The bad news is that it's the chuck that is out of truth. Either Newton mounted it badly (and I don't want to believe that) or it has had a clout and what has bent is the soft brass backplate of the chuck. What I shall do is skim the backplate up and remount it. I shall also make a new backplate for another small three jaw I have which I know is accurate. It's a new one and I have the outside jaws as well so I can have the luxury of two chucks and no jaw changing.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

TOM PHILLIPS

|

Posted - 28/01/2007 : 19:00 Posted - 28/01/2007 : 19:00

The handle looks fine to me Stanley,dosnt look out of place.Good news with the Mandrel aswell.

"Work,the curse of the drinking class"  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/01/2007 : 07:02 Posted - 29/01/2007 : 07:02

I've skimmed up the backplate of the chuck and re-fitted it and it's perfect. I have tried the other chucks that Newton mounted and I'm sorry to say they have the same fault, I hate to think it but he didn't take enough trouble making them, either that or they have distorted over the years because of stresses coming out of the casting. Could also be because a chuck got jammed and a hammer was used to slacken them off. Whatever, I am working my way through them and did my first turning on it last night re-facing the brass back plate. Brass chips all over the carpet! Had to have a good vacuum up afterwards. Lathe itself turns perfect, no play or chatter, plenty of power and very easy to use the handles. That's more important than it sounds, you need comfortable controls to get perfect cuts. I shall crack on with it today...... Very Happy Bunny!!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/01/2007 : 12:14 Posted - 29/01/2007 : 12:14

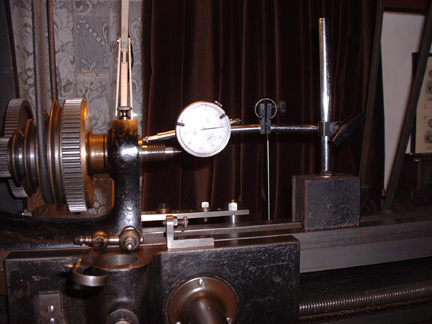

I've sorted another chuck out this morning, an old Burnerd. Here it is in the lathe and the piece of silver steel with a point on it is a very simple and accurate way of telling how accurate the chuck and mounting is. Take it from me, this is close enough for anything I'll ever want to do and only a high quality precision tool room lathe and chuck could do better perhaps.

This might be a good place to say something about accuracy. I always go back to Johnny Pickles. He never used a micrometer in his life, or if he did he kept it very quiet! There is a story that he was once walking through the shop in his later years when he saw one of his men using a micrometer. The lad noticed him watching him and said " It's all right Mr Pickles, I'm just roughing out, I'll finish it with the calipers!" Johnny smiled and walked on.

The point is that so many people get so wound up about accuracy it stops them from getting anything done. The best is the enemy of the possible. You have to decide what standard you want and stick to it and it has to be attainable. That's why the pic above shows acceptable accuracy.

Apart from the operator's skill there are three things that decide the final accuracy of work in the lathe. The standard of accuracy in the lathe, the accuracy of manufacture of the chuck and the precision with which it is fitted to the lathe. The lathe is OK, it's accurately made by a craftsman, despite its age it is in good condition and it all checks out. In this case, the old Burnerd chuck is a good one and so there's a good chance it will be accurate. It's no good going to a lot of trouble with a cheap or worn out chuck. Once you have the lathe and the chuck all you have to do is mount the chuck on the lathe in such a way as to preserve all the original virtues of accuracy and not introduce any errors.

The chuck is fitted to the lathe on a screwed nose with a plain section at the back and a collar or register against which the chuck butts up when screwed fully home. It is this register and not the thread which ensures accurate fitting. Almost all chucks are in two parts, the body of the chuck as manufactured and the back plate which has to be made on the nose of the lathe which it is going to be used on. So, you start off in an accurate lathe and make a blank back plate, all you are doing is boring it the correct size, threading it, and turning an accurate boss and register face on the back. If all these operations are done without disturbing the blank in the chuck the bore, thread and register will be concentric.

Take the prepared blank and mount it on the nose of the lathe which the chuck has to fit. Turn the face to the correct dimensions and make the register on it which will fit into the register recess on the back of the chuck. This register boss has to be dead accurate and the only way I have ever found to do this is to get it somewhere near and then reduce it carefully, trying the chuck on it after every cut, until you have a perfect fit. Providing you have sharp tools and take your time this is straightforward, needs no measuring tackle and is dead accurate. Once the back is finished, take it off the nose and drill the holes for the fixing screws which attach the backplate to the chuck body. Then put it in the lathe and do the silver steel pointed bar test. Don't expect it to be perfect but accept reasonable accuracy. Remember that starting from the baseline accuracy of the lathe, everything you do introduces more error unless you are very lucky. That's it, a perfectly fitted chuck. Just one thing to remember, most chuck backs are made from castings, either iron or non-ferocious. Castings always have stresses inside them and as you machine them these come out and distort your work. You have to accept this. Over time more stresses come out and it's always a good thing to occasionally strip the backplate out and give the registering surfaces a light skim. I suspect it is this which made the chucks inaccurate in the first place but they were doing the job so Newton never bothered to correct them. He was too good a turner to make them wrong in the first place.

One last thing, turning brass in the front room is great but it gets everywhere and I have to be very clean and vacuum up afterwards! Good job I haven't a house-proud woman to contend with.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/01/2007 : 17:59 Posted - 29/01/2007 : 17:59

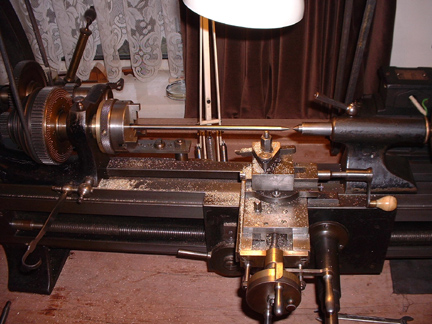

Another chuck fitted. This is a Polish chuck and I knew the importer. He told me that when they made the chucks they graded them according to accuracy and if they were short on an El Cheapo order they slipped some of the better ones in. This one is tool room quality. Note the register on me pointer test, It doesn't get much better than this. Very pleased with it. Tomorrow I shall make a faceplate for it........ Deep Joy!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

TOM PHILLIPS

|

Posted - 29/01/2007 : 23:00 Posted - 29/01/2007 : 23:00

Stanley,I was talking to a stonemason once when he was carving something,it was an excact carving of another piece he did earlier,all the measurements were done with calipers and dividers,not a vernier in sight,it didnt have to be as accurate as a piece of engineering but the principle is the same ,I think....

"Work,the curse of the drinking class"  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/01/2007 : 06:15 Posted - 30/01/2007 : 06:15

You are dead right. If you wanted a piece of stone to be an exact mate of one you had already and got the best man in the world to measure it accurately and then sent a drawing to the mason he would have laughed at you. Give him the stone and tell him to make a mating piece and he would just do it with just ruler and calipers. Same applied to Johnny Pickles and Newton and me as well. Of course this can't apply to manufacturing things in bulk which have to fit every mating gizmo ever made, that's why drawings always allow a tolerance. Shed fitters don't work like that and this is why they use very direct measures. In my case, the register recess on the chuck is the best measuring tool of the lot. The old steam engine fitters worked like this and that's why the parts aren't interchangeable even on identical engines. You have to make replacements to fit, that's why they called them fitters. Engineer make problems, fitters solve them.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Big Kev

|

Posted - 30/01/2007 : 10:59 Posted - 30/01/2007 : 10:59

quote:

Big Kev wrote:

Without the benefit of a shed most of my "playing" is done in the house. The ongoing kitchen project is nearing completion. I just need something to put up on the wall above the cooker. Suggestions so far are a large clock or an old metal advertisment (OXO or similar) but I'm open to suggestions....

the other end of the kitchen/dining areas

Big Kev

It doesn't matter who you vote for, you always end up with the government.  |

Another

Traycle Mine Overseer

6250 Posts

|

|

Posted - 30/01/2007 : 14:51 Posted - 30/01/2007 : 14:51

Very nice Kev, all your hard work has paid off. You should be very proud. Nolic

" I'm a self made man who worships his creator"   |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/01/2007 : 15:13 Posted - 30/01/2007 : 15:13

There is enough room on that sideboard for a Lorch watchmaker's lathe..........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |