| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 16/07/2007 : 06:16 Posted - 16/07/2007 : 06:16

Belle, you are no trespasser, you know you are welcome any time, virtual or flesh. (Calm down Deadly, you can come as well!) Ian, everyone to his/her own bag. Can't understand how you managed to resist a lathe though after using one for the screwdrivers. Carve a rough spitfire with plenty of meat on and get it cast in bronze, then start filing and polishing. I eat a lot of fruit and meat, these eight hour days in the shed need fuelling! Steve, welcome to the site. I don't get worried about lack of response because I know a lot of people just like to watch and who knows, someone might get triggered off. What does worry me is that I might be seen as some sort of expert or shed god, that's why I am always honest and post the cock-ups. In truth I am a good rough turner with imagination and ambitions, nothing more. I once sold a Birch Lathe to an old tool room man near Hebden Bridge and when I went to deliver it he was making something on his Super 7B, I looked at it and told me he was a sod, it made me feel like going home and scrapping my workshop! he consoled me by pointing out that the price he paid for that skill was 45 years bent over a lathe. Mind you.... I'm improving. I can even sharpen a cutting tool now.....

Glad you liked the OT stuff. My main interest is getting Johnny's two lathes back into perfect running nick. Plenty on the site about Johnny, look in Stanley's View in Forums. He was a member of SOT and the Worshipful Company as well. Brilliant engineer. Haven't tried the cutting frame yet, if you've read the thread you'll see I got obsessed with the 1927 lathe and decided I had to stop refurbing and get on with something different. Mind you.... starting on four engines at once is overkill I'll admit but my daughters will be suited and I'll have a real engine in the compound, it will be a serious lump and I can play with that for years, Stevenson link, air pump, condenser ....... One thing I haven't sussed in Walshaw or Holtzappfel is what speed to run the cutting frame at. Any clues on that would be appreciated. My grandson thinks a lathe in the lounge is cool....... Jack the Lurcher has no problems with it and everyone who has seen it has been knocked out. Definitely an ornament suitable for any gentleman's home...... Enough, keep chipping in, you are welcome. Must walk Jack and get back to serious stuff in the shed. Two mandrels, two standards and then a bit of serious milling for the apertures on the side of the standards to give access to the crosshead and bottom piston rod gland........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Steve48

New Member

19 Posts

|

|

Posted - 16/07/2007 : 07:30 Posted - 16/07/2007 : 07:30

Thanks for the welcome. Actually whirling Dervishes and turning might have some common ground.....

The speed of eccentric cutting frames and others - fast........ trouble is with the eccentric cutting frame it has to be the worst design anyone could ever come up with, it just isnt designed to rotate, the out of balance nature of the beast forbids you to go fast as it will shake like a belly dancer. This unfortunately is not just because of the eccentricy which could be counterbalanced, but also the end of the tool the carriage itself which is offset to the centre of axis, in order to be able to cut zero, ie; a dot. Having that mass out of centre in both directions means counter balancing in the normal sense isnt an option, at every differet setting an entirely different scenario awaits.

I would add though on speed, fast is a relative term, as all these instrument were designed when the speed came from your leg on a treadle and through a couple of pulleys. Not fast as in todays world.

Your motor problem made me wonder. I rebuilt a period motor for my Rivett, well worth the effort, they dont make them like that any more. But the centrifugal switch wasnt working properly, like yourself I took it down and rebuilt it, then it didnt want to switch off, tricky little blighters these things. I tried taking it out of the loop to test it open circuited at run up, but found that wasnt possible as feed back from the windings tried to fry my electric meter. In the end the only way I could test and set it for speed was to drive the motor externally at a known RPM, with much tweaking and settling I was finally able to prove closed at start and open at run, failure to get this right will cause some difficulty and some possible damage to the windings.

Steve

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 16/07/2007 : 17:36 Posted - 16/07/2007 : 17:36

I got round the problem by sending both Horace Greens to the electric motor hospital at Nelson. I rang and reminded them about them only the other day.

Another full day in the shed....

All four standards have had the mandrel treatment and are all numbered and matched to their mandrels which will become the piston rod and crosshead. I scribed the 2 15/16" PCD of the holding down bolts as well, all done on the lathe at the same setting.

For sets of beds and putative piston rods all numbered and matched.

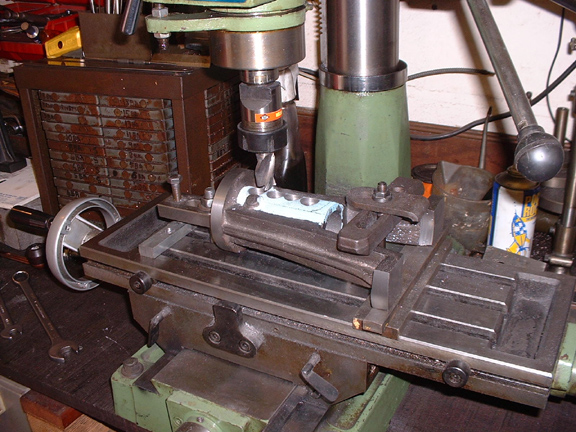

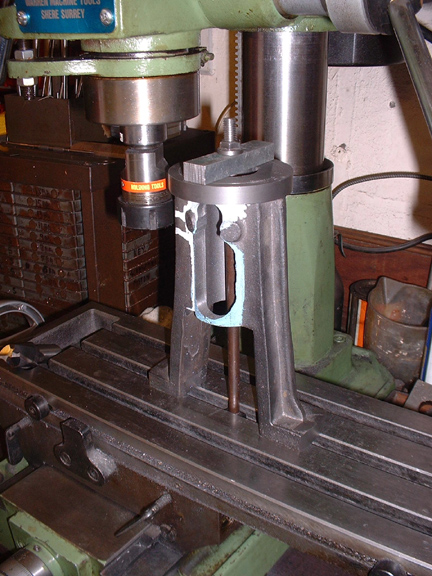

I like to think that many of the processes I go through in the workshop have a certain amount of precision and perhaps even artistry about them. Every now and again you have to forget all that and just go muck-shifting. The problem I have is that I need to cut two ports in each standard 3 1/2" x 1 1/4". They are for access to the crosshead and the piston rod gland. Problem is how do you do it? Fairly obvious that they have to be milled out, I've got past hours of chain drilling sawing and filing..... The best way I know of shifting weight of metal is a 3/4 inch blacksmith's drill so that's what I have done. It looks horrible doesn't it but I've got rid of half the metal and made the milling a lot easier. So I'm ready for some milling tomorrow. Every now and again you have to be brave and just rip the metal out, the only mistake you can make is to get too ambitious and take too much out.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 17/07/2007 : 00:28 Posted - 17/07/2007 : 00:28

Stanley

My phone line went down on Friday the 13th and the BT man didn't arrive until this morning (and its still not right!), since it was my weekend off, I've been a bit out of touch. Hope you don't mind a little "Rewinding".

I've only done a bit of fly cutting, with a single tool in the vertical mill, bit scary at first but, as you say, a nice finish. Using a single HSS tool also helps an idiot like me when it comes to sharpening. Normally I buck the issue by using tipped tools, but oh those blooming tiny screws they use, I've lost loads fo 'em!

Expanding mandrels - here I have to show my ignorance, I've never met such a beast. From the photos I imagine they use a self-centering wedge type action, but couldn't work it out. How do they work please?

Like Ian, I didn't enjoy metalwork that much, and woodwork is still a mystery - just don't like getting splinters. But once I realised that old bikes were held together with nuts, bolts, studs, spacers,bushes and washers which could all be turned and produced by my unskilled hands I just had to have a lathe of my own. There is something deeply satisfying about getting around problems with a bit of turning. As you keep showing us, a great deal is possible in the home workshop and the main thing is to have a go!

Crankshafts - Over a century ago there was a small engineering and foundry at Caernarvon called De Winton and Co. One of their main products was a small two-axle vertical boiler shunting locomotive for the local quarries. The power unit was basically an adapted 2 cylinder winch engine generally around 6ins bore by 10ins stroke . The crankshaft was also the driven axle so it had 2 journals each for the big ends and eccentrics, 2 journals for wheel bearings, 2 wheel seats and 2 seats for the fly cranks. They were made in one forging and the turner responsible prided himself that he could centre and turn one complete in 11 days!

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 17/07/2007 : 05:43 Posted - 17/07/2007 : 05:43

Remember what I said about learning from cock-ups? Steve mailed me this morning and sent me a pic of an eccentric frame and I have cocked in that the cutter is mounted wrongly and all I will be able to do is make circles and the clearance on the cutter will be wrong. Lovely, I shall go back to the drawing board when I am in OT mode again. Malcolm, Brown and Pickles used to make three throw feed pumps and the crankshaft started out as a billet of 90 ton steel three feet long and a foot in diameter. Four centres of course. It took about ten working days to chop one out. They tried forgings but they weren't strong enough, the stresses on a high pressure pump crankshaft are a lot higher than in an engine. You're right about the SC mandrels, just like a taper reamer but no thread for adjustment, just a plain sliding fit but once they are in place they jam.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Steve48

New Member

19 Posts

|

|

Posted - 17/07/2007 : 08:17 Posted - 17/07/2007 : 08:17

Well Stanley, you are most refreshing, there arent many who admit their mistakes like you do, I wanted to keep it a secret, didnt want the fan club to get disillusioned. I will go this far though, these eccentric frames are a nightmare and without having one to copy or viualise, I am sure most people would have made the same mistake myself included.

For those of you who wonder, the slide that is on the rotating shaft and carries the feed screw, has to be centre to the axis of the shaft on the face that carries the tool, then when the tool which is a flat of tool steel is sharpened, and shamfered to one face, the other being dead flat, will, if there is no eccentricity at all not cut a circle, but just make a dot.

For Belle, who loves the old names, there is an Epicycloidal cutting frame, a universal cutting frame, elliptical, horizonal, vertical. And to top it all off a Rose cutting frame and that one has nothing to do with flowers.....

I will let Stanley get on with the engines, enough interuptions from me.

Steve

|

Steve48

New Member

19 Posts

|

|

Posted - 17/07/2007 : 08:29 Posted - 17/07/2007 : 08:29

Harping back to Spitfires. We used to make miniatures of them from pre decimal pennies, by folding the penny in half, then gripping a small amount in the vice and opening the two edges up, and hammering them flat. This gave you a small top hat shape. The two slighty less than semi circles became the wings, the lump in the middle the fuselage, with just a little filling you ended up with a brooch sized Spitfire, if you were very clever a 1940 penny and some care left the date of the conflict and nothing else. It was a good skive when you had a boring job if nothing else.............

Steve

|

panbiker

|

Posted - 17/07/2007 : 16:16 Posted - 17/07/2007 : 16:16

Fantastic Steve, got loads of old pennies at home, I'll have to have a go at that.

Ian  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 17/07/2007 : 17:21 Posted - 17/07/2007 : 17:21

Belle, there is always the Goniostat for you to ponder over....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 17/07/2007 : 17:30 Posted - 17/07/2007 : 17:30

It's been a long day on the vertical miller. 8 heavy cuts at low speed and with a great deal of care. Don't want any cock-ups after all the work that's gone into these standards.....

All the cuts done, no slip-ups and just needs a bit of light tittivation with the file to break the edges.

I decided I wanted to mill the top faces of the feet to give a nice surface for the holding down bolts. Probem is I haven't a long enough cutter to get to them. I think we will have to go for plan 'B', a sharp file.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Steve48

New Member

19 Posts

|

|

Posted - 17/07/2007 : 17:54 Posted - 17/07/2007 : 17:54

I like easy options Stanley, a file inbetween that web is going to be damn hard going and the crust will make sure your sharp file wont be for long. What about waiting till the holes are there and spot facing it with a long drill using the clearance hole as the bearing. I have done this before with a decent sized Morse drill and just sharpening it to suit free hand, kind of like a slocombe bit but with the edges at 90 degrees, it works.

Another Belle word the "Pitman link" which goes on the crank, sounds bizarre, but true.

On the Spitfire saga, if you want to you can open the fuselage slightly in the later stages, but before its finished and solder a safety pin in the slot, brooch pin.........

Steve

|

andydiamond

Hairy Horologist

424 Posts

|

|

Posted - 17/07/2007 : 18:58 Posted - 17/07/2007 : 18:58

Hi all,

Some good work coming out of the shed Stanley - - - - - -

Do you want me to pick up the motors from the rewind shop and bring them over for you ?

Re cutter speeds - - - -I junked all the overhead motion stuff years ago, and now use a flexible drive and small high-speed motor for my Ornamental Turning, I run the cutters at approx 1000 to 10,000 r.p.m, and get a nice "off the tool" finish on the cuts ( for those who have not tried O.T., you cannot polish the decorations after making them, they have to be polished as they are cut ) - - - - -the only snag I have found is the tendency for the material being worked to burn if the tool goes blunt, so now I have to keep the tool sharp for a different reason than before !

Ian, looking forward to seeing your Spitfire on here, your posting on the French village was excellent, sorry I didn't get the chance to comment earlier.

Steve, nice to meet you on here, I have enjoyed your postings, keep Stanley on his toes !

Andy.

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 18/07/2007 : 06:06 Posted - 18/07/2007 : 06:06

Steve, Skin on castings isn't a problem and I have plenty of files.... Any part of the web in the way gets it! I looked at the old engine and that was what I did before. I shall drill the holding down bolts from below, freehand quite possibly and use the feet as templates for the bed. Andy, nice to know you are there...... I kept the overhead drive on the 1927 lathe for authenticity, I want to work the way Johnny did, all part of the refurb. For the big lathe I have a dedicated elctric motor driven OH unit with it's own clutch and will want to use that. The way I'm going I shall never get to try it out, making things that actually do something is much more fun!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Steve48

New Member

19 Posts

|

|

Posted - 18/07/2007 : 07:14 Posted - 18/07/2007 : 07:14

Hi Andy, and thanks for the welcome. You need to warn Stanley about those speeds. If you were to drive an eccentric cutting frame at anything like those speeds it would be prudent to switch it on from another room or building, it wouldnt be a funny outcome. And dont forget he has his TV in there as well as some personal belongings. ;-)

I agree with you there Stanley, bringing an old machine back to life is more gratifying than using it.

Steve

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 18/07/2007 : 17:51 Posted - 18/07/2007 : 17:51

Steve, I didn't actually say that..... I just needed to make something that actually worked when you put steam on it! I hit the standards with the file this morning and cleaned all the feet up in 45 minutes. All right, they would have been better if milled dead level but as Newton used to say, 'We're not driving 300 looms here!' I've just remembered, that statement originated with Johnny, he was in his shed one day with one of his mates looking on and he was finishing a crankshaft for a small twin cylinder compound marine engine. His mate chipped in and asked whether he had made a mistake as both crank journals were on the same centre and obviously, the LP journal should have been 90 degrees in front of the HP. Johnny smiled, pulled the shaft out of the lathe, heated the middle main journal until it was bright read and then twisted the shaft through 90 degrees. He then put it back in the lathe, tapped it straight and put the final finish on the main bearings. 'It'll be alright. It's not driving 300 looms...' He was right of course, if there is a short cut that attains the objective in view, use it. That little engine ran perfectly on steam. So, my feet, though not perfect, will do fine.

All four standards finished up to the point of a good wire brushing, some holes to drill and happen a coat of paint. All mandrels, standards, foundation plates and box beds are numbered and oriented properly.

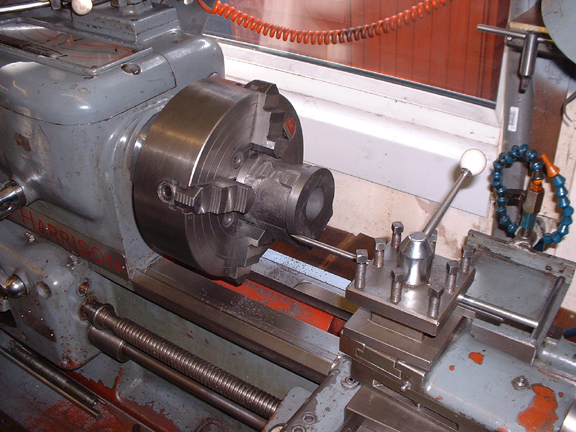

Different shaped casting thank God! We have two rough faces and so the next job is to get a finish on the edges of the flanges top and bottom. These have to be central to the casting as they look bad if they don't line up with the foundation ring when fitted. Never trust the core, it will always be out of centre. Set the cylinder up so that you get a true circle with the least amount of meat removed. Then turn the cylinder over, line up the true circle you've just cut with the concentric rings on the turntable and mill the top flange off.

All the cylinders cleaned up, including the big one.

Four jaw back on the lathe. The chuck is grabbed and somewhere near centre and then faced off to dimension. Then I'll turn it over and grab ot again but this time get the flange dead centre. Face the other end and then bore to finished size. All this is for tomorrow......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

|

|

|

|