| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

29/07/2011

:

06:27 Posted -

29/07/2011

:

06:27

|

New start as old topic was getting too big. Here's the LINK for the original topic.

Sheds are centres of honest endeavour and sanity, rare things these days. Please join in and tell us what you are doing in your shed. All are welcome!

[By the way, if I occasionally seem to be stating the bleeding obvious, it's because I'm aware of the fact that not everybody has the same experience so please forgive me.]

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 23/12/2011 : 05:55 Posted - 23/12/2011 : 05:55

Brad, when I was researching water power in the Lake District for the old DOE I went into one house where they asked me what THAT was, pointing to an iron shaft running the length of the ceiling. They had bought the house and didn't realise it was an old water powered bobbin mill and further, that the funny thing in the cellar was an operational water turbine! No probs with a home generator there! Even the 12" diameter feed pipe was still in place and carrying water.

Quiet careful day yesterday

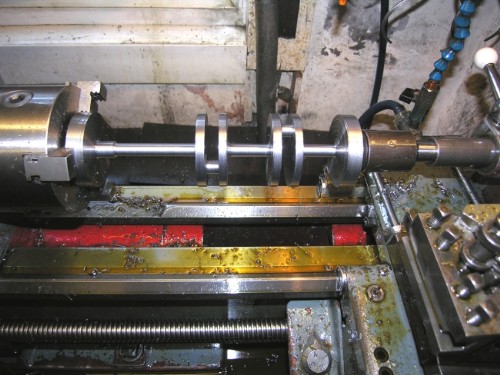

LP flange reduced to size and all the faces of the crank discs cleaned up to make it look as though someone cared. Crank jornals polished with emery strip.

Close of play. The flange at the HP end has to come off and the LP end needs to be cleaned up. Usual problem with harmonics from the gearbox so I am going to try putting the shaft in Johnny's big belt driven lathe to see whether that cures the problem. If not I shall have to do the best I can. Funny things is that harmonics only kick in when turning the face, no probs with the sides of the discs. Might try a diffent speed..... Whatever I do it will be careful!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 23/12/2011 : 10:20 Posted - 23/12/2011 : 10:20

Just in case anyone has a heart attack when they log on and find no work has been done today.... I have had a word with the managing director and bearing in mind the fact we had a stressful afternoon yesterday socialising, we have agreed to have an easy day tody. No Shed work and no Letcliffe as it's wet and miserable. We shall do a b it of light cooking and baking and generally slob about! Normal service will be resumed tomorrow.

Mind you, I've been thinking of putting the fixed steady in to see if it will damp the harmonics.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 24/12/2011 : 04:51 Posted - 24/12/2011 : 04:51

Having a day off was a good idea. I sometimes wonder if me old knees are giving me a message, far better this morning after a rest!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 25/12/2011 : 07:02 Posted - 25/12/2011 : 07:02

Normal service was resumed yesterday. Put the first shaft into Johnny's big lathe and turned the flange off with no dramas and only very slight harmonic buzz on first cuts. So nice to use this lathe for serious turning after all the effort I put into bringing it back from the dead. Johnny was looking over my shoulder and nodding I think! By the way, I have the gearing set up for low speed on the lead screw so had the benefit of auto feed for the cut.

I had a thought about the other shaft and set it up in the Harrison. I remembered that I had no problem with harmonics on the plunging cuts to tidy the faces up.

Close of play. The facing cuts on the flange worked perfectly. Notice how thin the final disc was, it's laid on the bench. Perfectly concentric and even. I trepanned it off when I got it this then, no problem.

The shafts are finished apart from a bit of titivating to get rid of the centre hole in the HP and and parhaps do something about the cemtre holes in the LP flange end. Not made my mind up about that yet.

Next thing will be to fit the shafts into the bearings. Ir will be nice to have a bit of fitting to do! However, there could be a problem. At first glance it's going to be quite a fiddle threading the shaft into the space under the cylinders. If it proves impossible there is an easy solution, take the cylinders and stanchions off in one lump, only ten nuts on each engine, It might not come to that.....

A nice day, very satisfying. The rewards for honets endeavour can be difficult to attain but are the best quiet satisfaction I know!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/12/2011 : 04:40 Posted - 26/12/2011 : 04:40

I decided to fit the finished shaft in the number one engine. I had to take the LP end front stanchion out to get it in and reliexe the iside radius of the outboard HP pedestal bearing but otherwise a perfect fit and turns easily but with just the right amount of drag for new bearings.

However.... That flange on the LP end is all wrong and will have to come off! It's overhung too far and means that in order to get an LP eccentric on I shall have to do some serious fiddling with a split eccentric. Main thing is it doesn't look right so it will come out, have the flange removed, the shaft end tidied up and a 1/8" keyway milled in the end.

There's another adjustment that needs doing. The inboard crank disc on the LP journal clears the aperture in the bed but only just. I shall take a skim off it and give it slightly more. None of these things are mistakes, just adjustments. The main thing is that the shaft fits nicely, and of course lessons have been learned for the other shaft.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 27/12/2011 : 05:21 Posted - 27/12/2011 : 05:21

I started the day by pulling the first engine down again after identifying all the adjustments I wanted to make.

I gave some of the pedestal brasses a bit more clearance on the faces.

Skimmed the offending LP crank face down a bit and then took the LP flange off and rebuilt the engine. Much improved and recognise that what I was after was giving the shaft a bit of room to float in the bearings. Watch any engine as it runs and you'll find that they all have a bit of float in the crankshaft. Theoretically they don't need it but over the years you'll find they need some play to accept slight misalgnments which can be due to all sorts of things. One of the most common is settling of the beds. One thing is certain, they run more comfortably with some play in the shaft.

I got the shaft out of number two engine by taking the pin out of the bottom of the LP stanchion, it sprung sideways enough to allow the crank discs to pass it. Identified where things needed easing and did the same as on Number one.

When I had both engines back to gether I tightened all the bearing caps down 'til the shaft was solid and then slacked back until it could be turned using a dog usually used with the catch plate when turning between centres. Tightening the bearings forces the shaft into them and makes sure that they can seat properly.

Close of play. The engines definitely look better without that flange! Didn't bother cutting a keyway on the shaft end, if anyone wants one they can do it themselves!

What I want to do now is set the engines up so I can drive them via the shaft end and run the bearings in. I can turn the shafts, just, at the moment but it will make fitting the con rods and valve rods much easier if the shaft is run in and can be turned easily. I'm letting my mind wander round this at the moment. I fancy holding the shaft end in the chuck on Johnny's big lathe and packing the engine up on the lathe so I can drive the shaft easily. Some running and oil with lapping paste in should do the trick!

Besides, my knees ache, I have been doing too much. I fancy sitting on a stool with an oilcan handy and me pipe going!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/12/2011 : 05:47 Posted - 28/12/2011 : 05:47

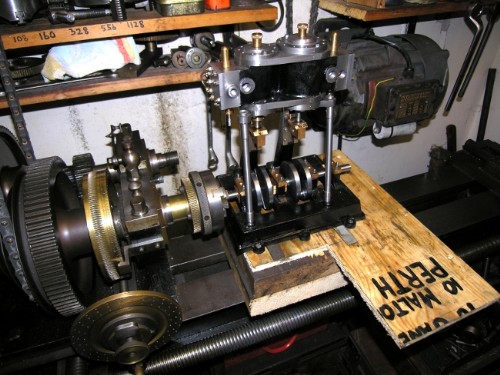

The flat bed on Johnny's lathe is ideal for mounting wooden blocks. I set the first engine up and ran it at 320rpm. I mixed some lapping paste with WD40, got it in the bearings and then tightened them down as it ran 'til they started to heat up, then slacked back a touch. All the bearings have full contact and after a couple of hours of running and playing about the shaft is nicely bedded in.

I shall do the second engine today. I changed over to the scroll chuck so I could drive from the HP end, it makes it easier to get to the the motion. The plan is to run the second shaft in and then start making the motion and fitting it with the engine in this position. That way I can run each cylinder in as I fit each part. By the time I have finished the first engine it will be ready for pipework and I shall call it finished, then do the same with the other.

Nice to see the shaft running, it will be even nicer when the motion is coupled up.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Bodger

|

Posted - 28/12/2011 : 11:41 Posted - 28/12/2011 : 11:41

Stanley, belated seasons greetings, i just thought you may be interested in this link on how to re align a crank web if the one without a key moves !!

http://users.telenet.be/doxford-matters/tekst/Re-alignment%20Eastern%20Rover.pdf

some inteesting pics on the site Bodger

"You can only make as well as you can measure"

Joseph Whitworth

|

Bodger

|

Posted - 28/12/2011 : 11:53 Posted - 28/12/2011 : 11:53

Scroll down to pics, the one entitled 'guaging main B journal', i think this mike is a little bigger than yours

"You can only make as well as you can measure"

Joseph Whitworth

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/12/2011 : 06:43 Posted - 29/12/2011 : 06:43

Bodge, an interesting read. Marvellous what can be done by competent men in a desperate situation. Newto swore by shrinking cranks on and crank pins. He always gave them just over one thou nip for every inch of diameter.

Nothing very exciting to report. Here's the number two engine mounted on the lathe and running at 320rpm. Didn't use lapping paste as it ran in easily and quickly. I ran it for about an hour continuously and all is fine so it will stay there while I do some measuring and planning for the con rods.

Bahrett's con rod design is based on castings which I do not have so once again I am going to have to use my head. I have been letting my head roam round the subject and I have decided on the simplest design possible. I want to avoid the old-fashioned and messy method of splitting the bearing and soldering it together for boring. I shall make it and bore it using the adjusting bolts to hold it together. It'll all become clear....

First thing to do is work out how much room I have in the bed plate aperture, the bearing has to clear the casting! Next thing to realise is that the con rod lengths are not necessarily identical so I shall do one cylinder at a time. I shall make the rod when the bearing is in place and I can measure accurately, The rod will be connected to the bearing by the adjusting bolts. If I get the bearings right they can be dead tight. All I have to do is arrange it so that there is 1/8" clearance between the piston and the top lid at TDC and let the bottom end look after itself. If I got it right there should be 1/8" there as well.

So, a bit of thinking and planning, some careful measuring and into the treasure chest for materials! It will be a nice change from Crankshaft turning. All good stuff and a good result but not my favourite job! Glad we have it out of the way.

Won't it be nice to see a piston going up and down!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/12/2011 : 07:20 Posted - 29/12/2011 : 07:20

One of the great advantages of being old and having had plenty of time to collect stuff in a time when engineering was in decline and stuff was being thrown away is that I have quite a comprehensive range of mikes. This is the biggest, a Slocombe metric that equates to an 8-9" imperial. And yes, I have had occasion to use it !

It wasn't just surplus secondhand equipment. Would you believe I bought this Moore and Wright internal set for a tenner brand new? This was handy for me but so sad to see good machinery being scrapped. I was in Dixon's(?) at Worsthorne one day looking at a very large Polish horizontal boring machine. It was almost brand new and there were no takers so it was going to be scrapped. That was in the 1980s and I remember saying to the bloke that if we were scrapping good tools like that it didn't matter what we were told about the new economy based on the service industries, the end result would be a disaster. A country that doesn't make things is on the road to decline. Subsequent events have not altered that opinion. It was vandalism to let our great industries go to the wall. That was the time that Tommy Robinsons, Tathams and Petrie's old foundry were liquidated and demolished in Rochdale. It was like watching a plague sweeping through the town.....

Is it any wonder that I felt like some sort of dinosaur fighting to save the Ellenroad engine and the Whitelees? I think that most people simply didn't get it.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Mercury

Regular Member

233 Posts

|

|

Posted - 29/12/2011 : 14:50 Posted - 29/12/2011 : 14:50

Well, thank God that you did save them! A lot of folks these days don't seem to have any 'soul'. And that includes some 'older folk'. It isn't just confined to the young 'uns.

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/12/2011 : 05:22 Posted - 30/12/2011 : 05:22

It wasn't just me of course, I had a lot of help and luck and the climate was favourable in that we had the Manpower Services Commission as a good source of labour. I was talking to my mate Robert who has also done big heritage projects and we both agree that if we were offered the same chances now we would refuse them. No way they could be done due to the increase in paperwork and regulation and the absence of meaningful funding. Total cost of Ellenroad was well over £3million.

The bad news is that apart from the odd spell of running in, nothing done on the engines yeterday. I got embroiled in archiving last year's work.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 31/12/2011 : 05:22 Posted - 31/12/2011 : 05:22

Nothing done yesterday either. I am having a couple of easy days while I get over a bit of an upset caused (I think) by a tin of 'festive shorthread! I gave the engine about an hour's running. Nice mix of bronze and oil coming out of the bearings as they argue with each other!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/01/2012 : 05:35 Posted - 01/01/2012 : 05:35

Still feelimng delicate so taking it easy.... However, I ran the engine for an hour and sorted out measurements of the bearings and found the stock they can come out of. Nothing actually made but it's progress of a sort. Sooner I feel better the better I'll be pleased!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |