| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 05/01/2007 : 10:18 Posted - 05/01/2007 : 10:18

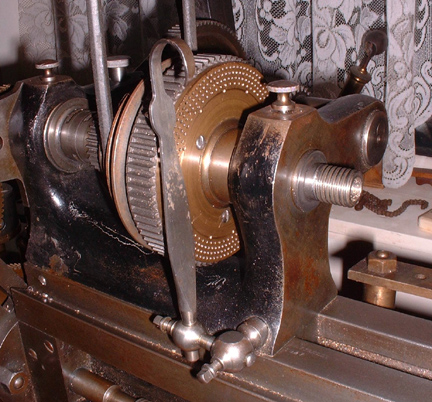

I was thinking about the effort that Wilkinson put ito making his tools attractive and here's another example. When Johnny made the 1937 copy of the Birch Lathe he needed a detent to register the dividing plate in different positions. I can think of a lot of simple methods but here's what he did. It's complicated, beautifully shaped and totally functional. Look at the plug in the oil hole for the headstock bearing. dead accurate, slghtly flared so that it fixes firmly and shaped before knurling. A wooden peg would have done the same job! He was right of course because a mundane industrial tool was transformed into a work of art.... Now that's craftsmanship!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

TOM PHILLIPS

|

Posted - 05/01/2007 : 11:47 Posted - 05/01/2007 : 11:47

Thats a piece of highly skilled engineering on its own really,am i right in presuming that its works like a spring with pegs that locate in the holes on the plate?,ive seen alot of milling and turning but ive never really studied the machines,forgive my ignorance if iam way of the mark.

"Work,the curse of the drinking class"  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 05/01/2007 : 17:39 Posted - 05/01/2007 : 17:39

You've got it Tom. The holes in the plate are location points for dividing a circle. Each row has different numbers that can be divided in different ways. So if someone wanted a gear wheel with 30 teeth in they would use every third hole in the 90 circle. It can get a lot more complicated than that, if you look at the dividing head above you'll see it has a straighforward division plate with 3 rows of holes, 100, 68 and 36. You can divide a lot of different numbers with divisors of those numbers. However, look on the front and you'll see another dividing plate connected to the mandrel through a worm gear. The combination of holes on that is 30, 28, 27, 26, 12 and 11. Using that in combination with the number of teeth in the worm wheel means that you can divide an almost infinite number of teeth. If you want to get an idea, look up 'tangential dividing' on the web. I would have to do it before I used it, I've forgotten the combinations. Very useful not only for gears but marking divisions on a register plate, fluting for ornament or even making fancy pastry cutters for herindoors! Sheds are wonderful........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

TOM PHILLIPS

|

Posted - 05/01/2007 : 23:38 Posted - 05/01/2007 : 23:38

Thanks for that Stanley,But ,I always thought a lathe turned steel,you talk about cutting teeth,does this make it a milling machine aswell.?

"Work,the curse of the drinking class"  |

karlelden

|

Posted - 06/01/2007 : 03:12 Posted - 06/01/2007 : 03:12

Stanley said, "A wooden peg would have done the same job! He was right of course because a mundane industrial tool was transformed into a work of art.... Now that's craftsmanship! "

That's it exactly! Much of American engineering is merely mundane industrial application. Brits took the extra time and energy to turn out works of art.

Edited by - karlelden on 06 January 2007 03:13:08

Karl Elden |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 06/01/2007 : 08:37 Posted - 06/01/2007 : 08:37

Tom, a lathe is the most versatile machine tool ever invented. You can do milling in it and use almost any stock material from wood and ivory through brass and gunmetal to steel. Think of a lathe sood on its end and you have eaither a vertical borer or a milling machine.

Karl, you're right. If you have a look at the history of machine tools you will see that the US went for cheap and cheerful with light beds in the early days and the Brits went for weight and looks. The reason was the economic circumstances, availablity of skilled labour and culture. This doesn't mean the US machines were bad or all the British good. There is a lot of literature on this. Where the US scored heavily from 1890 onwards was in tooling and small items like lubricators. A tremendous amount was imported into UK. Look up Lunkenheimer for a good example. Eventually some great machine tools came out of America and major innovations like the pocket micrometer. I have one of the originals made by Brown and Sharpe, Providence, RI. Tiny and still accurate.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 06/01/2007 : 10:48 Posted - 06/01/2007 : 10:48

Here is the Brown and Sharpe 1868 micrometer. There had been earlier attempts at a portable measuring device but this one, the 'Pocket Sheet Metal Gauge' was the first practical instrument that combined all the features of the modern micrometer. It won't be 1868 manufacture but is certainly the 1868 design and is still dead accurate.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

TOM PHILLIPS

|

Posted - 06/01/2007 : 12:15 Posted - 06/01/2007 : 12:15

Stanley,is it a 0 to1/2",we always used a 0to 1" for gauging the thickness of steel chimneys which were either 1/4 " plate or 3/8" plate,until the introduction of ultra sonic testers ,the design of the micrometer as not altered at all,wonderful tool.

"Work,the curse of the drinking class"  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 06/01/2007 : 16:50 Posted - 06/01/2007 : 16:50

It was intended mainly for sheet metal and is about 0 to 5/16". Calibrated in 1/1000s.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 08/01/2007 : 10:19 Posted - 08/01/2007 : 10:19

Call me a bit slow but this morning I realised just what was in Johnny Pickles' mind when he made the dividing head above. One of the nice things about sorting through any sort of machinery, including big engines, is that you get an insight into the men that built them. You find there mistakes, their novel ideas and the short cuts they took. I knew what the dividing head was for and how it worked but I had never really dug into why Johnny did it this way. There are much simpler ways of cutting a gear in the lathe with overhead driving gear. I went to the head this morning to make a detent for the division plate and I realised what Johnny was thinking about when he made it. He was making fairly substantial steel gears for turret clocks and a horizontal milling machine gives a much more effective cut, quicker as well. So, by making a nose on the head that would take the chuck off his lathe he made it possible to bore a gear blank, make a mandrel in the lathe for the blank and then finish the blank, apart from gear-cutting, all on the same centre, thus ensuring that it was perfectly concentric as long as remained undisturbed in the chuck. He could then screw the chuck off the nose of the lathe, mount it on the dividing head and be certain that it was near concentric as possible. As long as the nose and register on the dividing head are accurate, the gear is forced to be right. He could then support the mandrel with a tail stock and cut the gear accurately. So, what looked like a long way round is actually the fastest and most accurate way to generate a gear wheel. What a good engineer that man was........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

TOM PHILLIPS

|

Posted - 08/01/2007 : 21:12 Posted - 08/01/2007 : 21:12

Stanley,from the little I know about this type of engineering,most of the time is taken up setting out the piece that you will be working on,but if its set for several jobs on the piece ,this would also save alot of time and as you say Stanley ,much more accurate,Ive always been quite envious of people who can do this type of work and to such accuracy,most of the time i work to "rack o th'eye",the man was before his time....

"Work,the curse of the drinking class"  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 09/01/2007 : 07:02 Posted - 09/01/2007 : 07:02

You're right Tom. That's why it's always handy to have more chucks than you need. If you are half way through a job and a rush one comes in you can just screw the chick and workpiece off the nose, do the urgent job and then return the workpiece undisturbed to the lathe. The same reason why a back plate for a lathe is always made on the nose of the lathe it is to work on. Modern methods of mounting chucks on locking studs help but are only found on bigger lathes.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Big Kev

|

Posted - 09/01/2007 : 11:52 Posted - 09/01/2007 : 11:52

Without the benefit of a shed most of my "playing" is done in the house. The ongoing kitchen project is nearing completion. I just need something to put up on the wall above the cooker. Suggestions so far are a large clock or an old metal advertisment (OXO or similar) but I'm open to suggestions....

Big Kev

It doesn't matter who you vote for, you always end up with the government.  |

TOM PHILLIPS

|

Posted - 09/01/2007 : 12:06 Posted - 09/01/2007 : 12:06

The wife says a stailess steel rack ,hanging from the ceiling,I then told her you was 6'7",she thinks it might not be practicle anymore,I'd go for the advertising board,nice job Kev,very similar style to ours,obviously a man of taste.

"Work,the curse of the drinking class"  |

Ringo

Site Administrator

3793 Posts

|

|

Posted - 09/01/2007 : 12:14 Posted - 09/01/2007 : 12:14

Looking good Kev here are my 2 suggestions for what to put on the wall

Item 1

Item 2

|