| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Invernahaille

|

Posted - 25/02/2007 : 15:30 Posted - 25/02/2007 : 15:30

Not sure Stanley. Could it be for key cutting?

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 25/02/2007 : 17:15 Posted - 25/02/2007 : 17:15

The short answer is I don't know Robert. I have an idea in the back of my mind that it's for gear cutting using another gear wheel with the same no. of teeth as a register instead of a dividing head. Johnny was always up for using the simplest method and what we forget is that every mill had thousands of gears with varying numbers of teeth which were used as 'change wheels' on looms. They were relatively rough gears but the divisions were spot on and just right for duplicating a number of teeth. The thing that is bothering me is that if this was right, how was the milling spindle driven?

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Invernahaille

|

Posted - 25/02/2007 : 17:27 Posted - 25/02/2007 : 17:27

I saw that Stanley. Thats what made me think of key cutting. My understanding of change gears on textile machines is that in days of yor, (early twentieth century) they were casted out of cast iron and then the gear teeth were just fettled (in the engineering sense) to an acceptable standard.

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/02/2007 : 06:19 Posted - 26/02/2007 : 06:19

On common Lancashire Looms they were used as cast, no fettling unless there was an obvious fault. When Johnny made the 12 inch lathe he got loom pulleys, turned the teeth off them and cleaned them up and then cut the gears accurately for the sizes he wanted. I've just counted them and there are about 45 change wheels with it, far more than a normal lathe.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Invernahaille

|

Posted - 26/02/2007 : 12:36 Posted - 26/02/2007 : 12:36

Oh right.

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/02/2007 : 17:05 Posted - 26/02/2007 : 17:05

I've taken the spindle out of the Harrison mill and installed the ETM collett chuck ready for the hob.

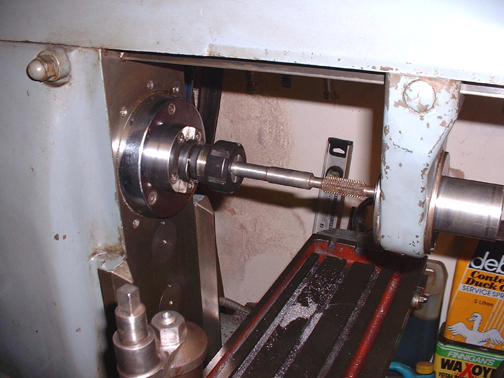

Here's the everyday spindle out of the mill and the collett chuck that will replace it. Very rigid mounting on big bearings, so there will be no problem driving the hob. I've cleaned the hob up and am making a push to steady the tail end of it. I've never used the mill in this way before, it'll be interesting. Think of it as a vertical mill laid on it's back. I have a big angle plate and have often thought of using the mill like this to generate plane surfaces because the setup is so rigid, far more so than a vertical mill as the castings of the standard are massive.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 27/02/2007 : 17:38 Posted - 27/02/2007 : 17:38

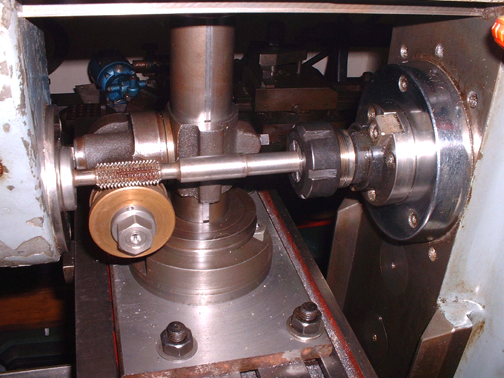

The bush is made and here's the set-up that will be installed in the Harrison mill with the hob being driven by the collett chuck. The bushes aren't anchored in the supporting bracket as they won't have any longitudinal forces on them so they won't try to move. Makes it easier to set up as well if I need a bit more clearance.

Here's the hob set up in the mill. Getting close now!

All ready for the off. The mill is on its lowest speed, 67 rpm. All I have to do is take my courage in both hands and press the button to enter the wonderful world of hobbing! Can't put it off any longer, now we'll find out if I have got it right!

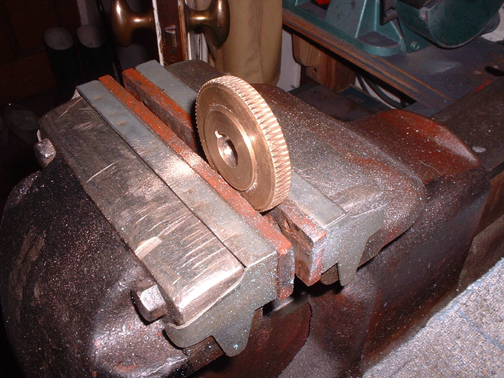

I'm tempted to say that there's nowt to it! Here's the test blank I cut and although not perfect, it is a worm wheel. Funny thing is I'd calculated 75 teeth and it hobbed at 82! I went back through the calculations and found I'd made a simple arithmetical mistake. The other thing I've learned is that it will be better to turn a hollow circular groove in the edge of the blank and that the bottom of that curve, less about a third of the tooth depth is going to be the PCD. I've noticed also that Johnny turned the shoulders off the blank as well before cutting so that there are no delicate feather edges on the gear when cut. All told, very satisfying and a good test. The set-up is perfect, plenty of adjustment available and as steady as a rock. Just goes to show that a bit of time spent on the setup is well worth while.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Mercury

Regular Member

233 Posts

|

|

Posted - 27/02/2007 : 19:35 Posted - 27/02/2007 : 19:35

Now we're talking! After the fascinating preparation and setting-up comes the end result!

Cracking stuff Stanley.

PS Presence of fragrant tobacco device noted!

|

Invernahaille

|

Posted - 27/02/2007 : 19:46 Posted - 27/02/2007 : 19:46

Is that brass or phosphor bronze Staley?

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/02/2007 : 04:39 Posted - 28/02/2007 : 04:39

Not sure, it's a piece of scrap. I'd say bronze from the colour. Neville, my feelings exactly. I was beginning to wonder why I was spending so long on the set-up, it felt like displacement activity but it was the right thing to do. The short mandrel on the fixture hampers me a bit but there's enough ajustments to get round that for all normal sized gears and of course the shorter it is the stiffer the set-up. The key is in the measurement and I'm going to have to be very careful about that. The only disappointment was that even though the worm wheel I made fits the 1927 lathe mandrel the dividing gear and worm fouls in the mounting before it gets close enough to go into gear. It was designed for a worm wheel about 4 inches diameter and this is only two. Now for a bit of working out!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/02/2007 : 04:43 Posted - 28/02/2007 : 04:43

PS. I made a mistake when I was describing the calculation. I have to work out the PCD. add a third of the tooth depth and then add the depth of the preparation groove. This will give the blank size. And yes, the pipe is an essential piece of the equipment. There was a pot of tea there as well. I'll bet Johnny was watching me yesterday and cheering me on!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/02/2007 : 10:51 Posted - 28/02/2007 : 10:51

I've been struggling with me figures all morning and have decided that I'm working this out the wrong way. I measured Johnny's worm wheel on the 12 inch lathe and worked it backwards and I have a feeling I am making a basic mistake by regarding the worm wheel as a gear wheel. I've used Johnny's sizing and arrived at a blank diameter of 4.9 inches. I shall count my teeth after a couple of cuts and see if I have the right number. If not it will be too many and I shall simply make it smaller and start again! Not very professional but I'll get a result.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Invernahaille

|

Posted - 28/02/2007 : 12:57 Posted - 28/02/2007 : 12:57

If at first you dont succeed. God loves a tryer Stanley. Keep perservering you will get there.

|

Mercury

Regular Member

233 Posts

|

|

Posted - 28/02/2007 : 15:02 Posted - 28/02/2007 : 15:02

So what's the cutting sequence Stanley? Do you lower the rotating hob down onto the blank, making he first row of 'teeth'. then raise it, rotate the blank and cut again, repeating until it's complete? That must call for very precise alignment.

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/02/2007 : 17:45 Posted - 28/02/2007 : 17:45

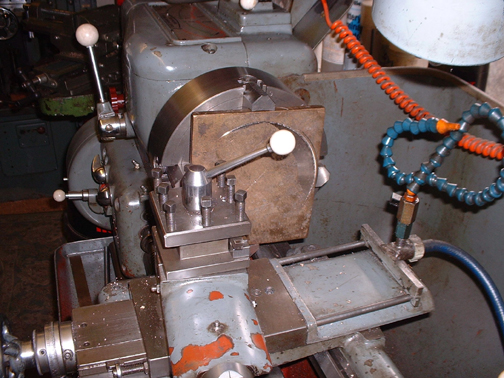

Hecky thump no! Just start the mill, shove the blank into contact with the hob and let it argue its way round (the hob rotates the blank, that's why it's called 'free-hobbing') once you reach the start point give it some more cut and carry on until it looks about right. Don't forget, this gear isn't meant to drive anything, it is simply a register.

First phase of getting the blank out of the plate I had is to get somewhere near a face, bore it 9/16" for the spindle and then trepan it out.

I've cut the keyway and am half way through making a mandrel to turn it on its own shaft to the blank size. Then into the mill!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |