| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 10/03/2007 : 06:12 Posted - 10/03/2007 : 06:12

Went into shed to start gear-cutting and finished up making a bunch of 9/16 BSF nuts. Johnny liked his BSF and they are very hard to find in odd sizes. Been held up a couple of times so I thought I'd cure that log jam. I don't know about you lot but I spend so much time looking for odd thread sizes I find it quicker to make them.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 10/03/2007 : 16:54 Posted - 10/03/2007 : 16:54

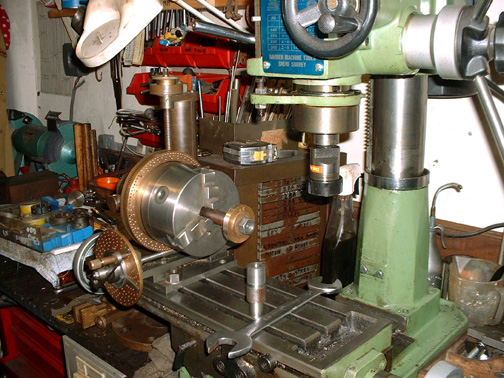

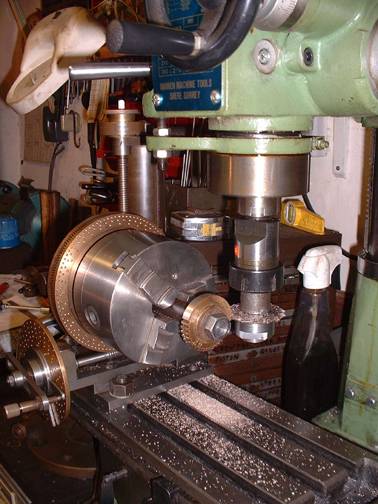

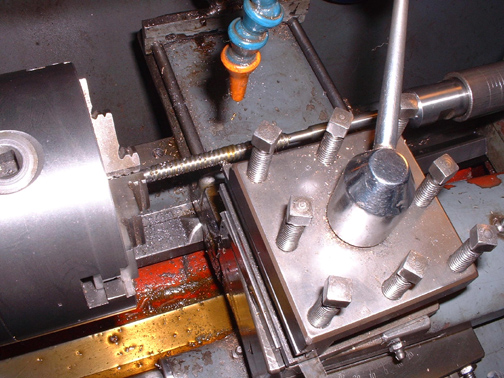

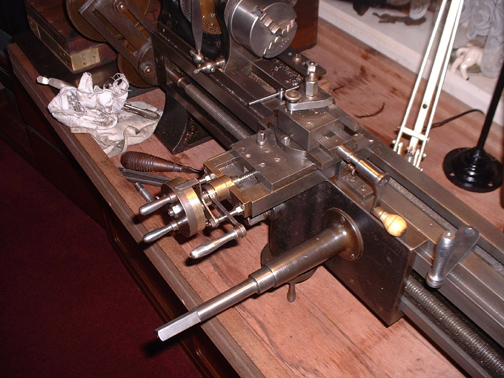

Interesting day...... The blank is ready and the chuck mounted on Johnny's dividing head. The gear cutter will be mounted on a short arbor in the ETM chuck. I got me books out and boned up on tangential dividing. It's a 35 tooth wheel and 180 teeth in the worm so 180 divided by 35 gives five and one seventh turns on the worm wheel plus 4 divisions on the 28 hole register. I noticed there was no set screw in the quadrant on the blades so a quick trip into the front room to turn up a 3BA cheese head screw and then I realised that the division plate had the number upside down at the bottom so I drilled another register in the plate so I could rotate it 180 degrees. I thoght I had an arbor that would do in the T&C grinder bits but no luck so I'm making one for the job which will do for the T&C grinder as well. You can see it stood on the miller bed, just needs a jeyway cutting in it.... I'm making the nut for it at the moment and, taking a leaf out of Harrison's book, I have put a very fine thread on the arbor to give a good grip. I have a one inch 26TPI brass thread die and matching taps so it gets the full treatment. I'll finish that in the morning, cut the keyway and make a few brass chippings. Only impoderable is that the gear cutter I have doesn't quite match the profile of the original gears but I reckon it's close enough. When Johnny cut his gears he'd make a fly cutter and use that.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 11/03/2007 : 07:09 Posted - 11/03/2007 : 07:09

Re-reading the above, of course I meant that to get the 1/7 turn you use 4 divisions on the 28 hole ring. Up early this morning after an early night, can't wait to get back in the shed!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 11/03/2007 : 17:27 Posted - 11/03/2007 : 17:27

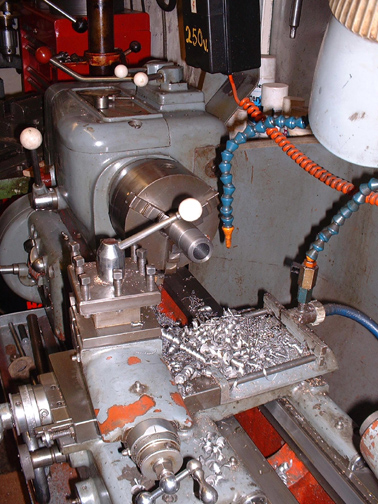

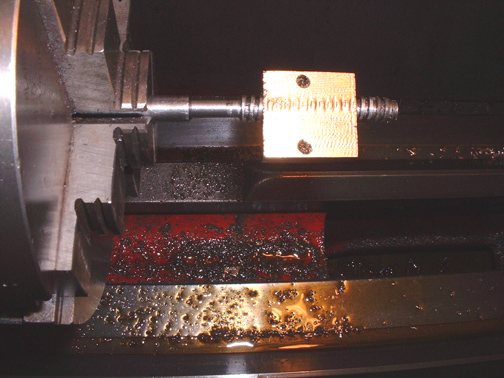

This pic is for Andy, I have an ideaq he thinks this is a magic lathe that cleans itself! Time for the swarf fairy I think.....

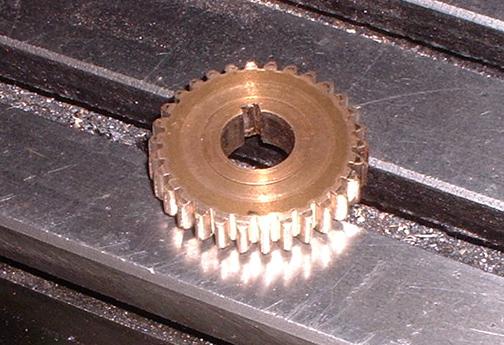

Gear cutting with Johnny's set up. Nowt to it! However, I got a nasty shock when I came to the last tooth, it was out of register. I knew it couldn't be the dividing and so put it down to me not tightening the chuck on the nose, probably because I was being careful not to put too much strain on the bif worm wheel. My 35 tooth wheel came off, a quick calculation for the blank, teth + 2 divided by pitch circle diameter. Back into the lathe, turn down to size and back in the gear-cutting setup.

Ten minutes later I had a thirty tooth gear...... Next job is to make the missing stud to carry the gear wheel on the banjo on the 1927 lathe. Then I can put an idler in and have the lead screw working the right way instead of being permanently in reverse. That means we can screwcut and have longitudinal feed.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 12/03/2007 : 06:17 Posted - 12/03/2007 : 06:17

I've been thinking...... I might not need another stud. I'll have a look at the 12" lathe and see how Johnny tackled it there..... Justhad a look and it's a good job I did. My problem is the shortage of gears, not studs so I shall crash on with getting the selection of gears right before bothering with making studs. I have some gears off a different lathe that need making the right bore to fit the 1927. We need some bushes!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 13/03/2007 : 06:20 Posted - 13/03/2007 : 06:20

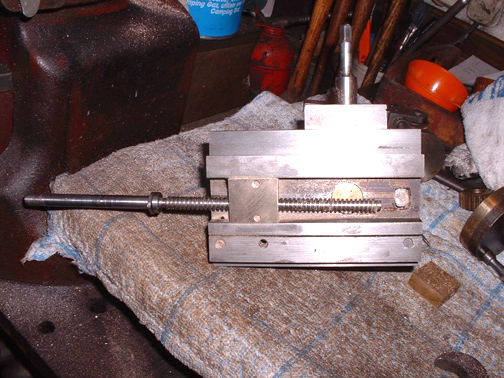

I don't know what came over me yesterday morning. I was firmly focussed on gears but then found myself taking the cross slide off the saddle on the 1927 lathe and stripping it down on the bench to get the leadscrew nut off as it has a lot of play in it. I happened to have some brass bar so I cut a new block out and found a piece of 5/16 silver steel to make a LH square thread 10tpi tap.

A few cuts later and I was ready to thread it and you know how I love square threads!

Despite very light cuts and plenty of cutting oil I broke the tool three times and the last time it damaged the thread so I have taken it out, cut it down to a normal tap size and I'll finish cutting it this morning. We'll see how far I get with this brainstorm!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 14/03/2007 : 06:36 Posted - 14/03/2007 : 06:36

To be honest, I was so disgusted with myself when I gashed the thread on the blank tap that I threw it in the bin but then sanity prevailed and I reckoned that I could get away with a short tap so I got it out and cut it down to size, banged it back into the lathe and carried on cutting 'til I got down to 6mm core diameter.

I tried the old nut on it and it was a loose fit which figured as it has had 80 years hard work.

Here's the finished tap after a lot of tapering, fluting and hardening and tempering. Looks a rough little baby but it cut the thread like a dream. By the way, I didn't go for too much engagement, I bored the nut 7mm to give me a better chance of a fit. As you know, I always confess my sins..... I but the new nut in the vice and started to thread it and couldn't understand why it was doing nothing but produce a tapered hole. I'd got that would up I'd forgotten it was LH thread! Nowt like an old fool. Ten minutes and a new nut blank later and the tap worked like a charm. The nut was a bit tight on the unworn end of the cross slide lead screw but I didn'r ease it as I knew the rest of the leadscrew would be more worn do I forced it on.

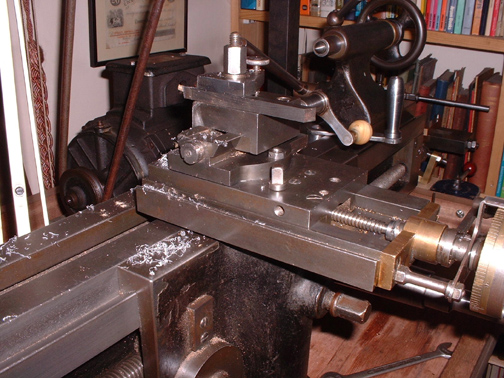

Here's the new nut married to the lead screw and installed in the slide. A better fit than the old one I think, Johnny must have been in a hurry!

Here it is re-installed in the 1927 lathe and a big improvement, still a bit of backlash of course as it's the 80 year old leadscrew but I reckon 60% better than the old nut. It's a shade tight at the moment of course but the brass nut will soon polish up with use. Well worth the effort. Now then, what can we do today.........?

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 15/03/2007 : 05:49 Posted - 15/03/2007 : 05:49

Ysterday was a bit more sensible...... I started by making a proper arbor for gear-cutting the new gears I need. Then I turned my mind to the brass gears I have which are the right pitch for the 1927 lathe but inch and a quarter bore instead of 9/16. So I made another mandrel and started making some bushes for them. Finishing them is today's task. There is another matter. when I was making the new leadscrew nut I noticed a threaded hole in the side of the cross slide block........ The neurones started working. Must do a pic for you.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 15/03/2007 : 06:00 Posted - 15/03/2007 : 06:00

When Nandy visited I pointed out the dovetail on the side of the saddle and we were wondering what it was for. While I had the slide in bits for the new leadscrew nut I noticed the threaded hole in the side of the block and it struck me that this was made for an auxilliary platform, geared to the top slide that could carry a steady or a back-mounted parting tool. Parting off from the back used to be very popular with light lathes because if you mount the tool upside down it is a far more reliable way of doing the job as it is tending to force the mandrel down into the nose bearing rather than lifting it. As most of the normal cutting forces lift the work and wear the top of the bearing, parting off in this way used the unworn part of the bearing, the bottom. Bit of thought needed on this I think!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 15/03/2007 : 12:54 Posted - 15/03/2007 : 12:54

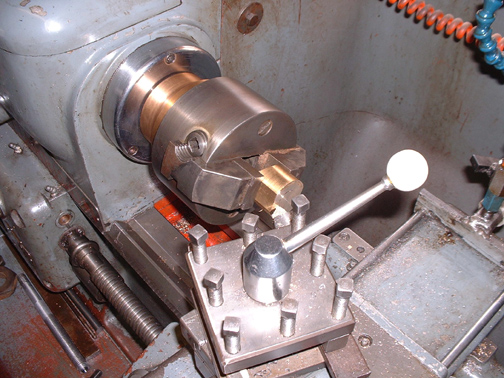

Getting on well this morning with the gears. Here are three already bushed. Interference fit with Loctite shaft grade adhesive and I shall stake them as well with dowels in the joint. Always was a belt and braces man!

I needed another bush and I had a peculiarly shaped gunmetal end which had two flats on it. Workholding small pieces for fairly heavy cuts is always a problem and here the old Cushman self-centering two jaw brass-finisher's chuck came in useful. You can never have too many types of chuck!

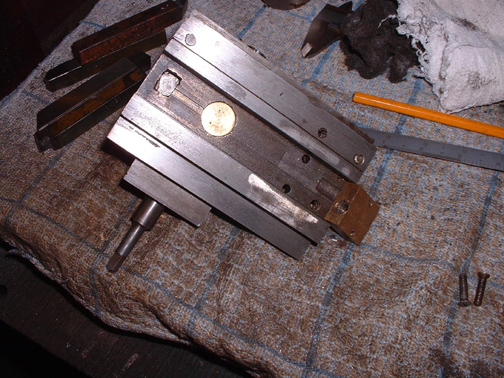

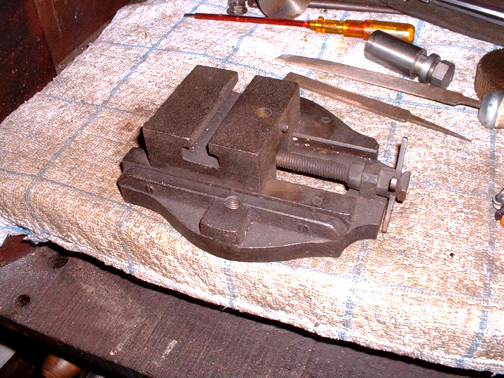

Right, there are lots of you watching me make mistakes but not many joining in and criticising! Here's a puzzle for you. What is it? You will go many a long day's march before you'll see another of these. I've never used it but you never know, one of these days it could be a lifesaver!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Ringo

Site Administrator

3793 Posts

|

|

Posted - 15/03/2007 : 22:16 Posted - 15/03/2007 : 22:16

Never seen such a thing before but it looks like it might fastenen onto the cross slide and with it having a t-slot in it something must fastenen to the top. Is it some sort of milling attachment for a lathe?

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 16/03/2007 : 06:40 Posted - 16/03/2007 : 06:40

You're getting very close Ric. I'll leave the answer a bit longer to see if anyone is old enough to remember them. Johnny Pickles or one of his generation would have known immediately what it is. Didn't get any further with the gears yesterday as Doc called round and we sat talking and watching Meg and Jack having a love-in..... They get on so well with each other, it's a treat to watch them.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Ringo

Site Administrator

3793 Posts

|

|

Posted - 16/03/2007 : 11:34 Posted - 16/03/2007 : 11:34

An attachment for putting radii on?

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 16/03/2007 : 15:35 Posted - 16/03/2007 : 15:35

Nope...... I'll post the answer tomorrow.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 16/03/2007 : 15:37 Posted - 16/03/2007 : 15:37

Actually, I can think of ways you could use it to machine a radius......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |