| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

pluggy

|

Posted - 03/01/2008 : 13:12 Posted - 03/01/2008 : 13:12

Battery was cheap, Having the clock restored would be expensive and as it takes up a lot of room, it should really pay its way as a timepiece in my opinion. I haven't burnt any bridges, all the original movement, weights and pendulum are still in the clock and as the clock will certainly outlast me, someone down the line may choose to spend a lot of money have it restored to a being a 'real' clock at some point in the future. Its in its third century now, the original maker will have long since 'shuffled off the mortal coil' and theres no reason being kept warm, dry and polished in a maintained house it won't last for the next 3 centuries. An upside is that whilst its running on a quartz movement the real movement isn't getting any more wear.

Different people have different priorities, having a quartz grandfather clock is clearly heresy to some, to me its a practical solution.

Need computer work ?

"http://www.stsr.co.uk"

Pluggy's Household Monitor  |

pluggy

|

Posted - 03/01/2008 : 13:46 Posted - 03/01/2008 : 13:46

In case anyone want to see what my quartz grandfather looks like :

I inherited it from my maternal grandfather back in the eighties. It was running on clockwork then, but it was tired and became increasingly unreliable before I doctored it about 10 years ago. My grandfather bought it in 1933 as part of a job lot of furniture in a Clitheroe auction house. I believe it was made around 1892. The dial has 'Ashworth, Todmorden' written on it. The dials in the centre of the clock (second hand and date) were missing when my Granfather bought it apparently, the phases of the moon at the top worked up until the 1950's when he had it disconnected because the movement was struggling to drive it. The original hands are polished brass and are have scroll work. They are in the back of the clock with the movement, being too heavy for the new battery movement. The glass has been replaced several times in its history, largely because of the tomfoolery of my mother and her brothers when they were kids.

Need computer work ?

"http://www.stsr.co.uk"

Pluggy's Household Monitor  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 04/01/2008 : 07:30 Posted - 04/01/2008 : 07:30

Each yo his own Pluggy. Malcolm, that's the conclusion I came to. The valves are seated and there's a nice sharp exhaust note, you could probably finesse the settings a bit, these are just done by eye as I was building it. Bottom line is the rings are sealing well, it goes like hell on 80psi and I have no doubt that if it were on a boiler it would be impressive and do the job. It's sat on a piece of towel in the kitchen while the oil drains off it, I had it flooded while it was running to wash the original flush of running in muck out. next week it gets a baseboard and starts life as an ornament!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Mercury

Regular Member

233 Posts

|

|

Posted - 04/01/2008 : 15:47 Posted - 04/01/2008 : 15:47

That's excellent, Stanley! I've really enjoyed watching the build process and especially the running engine. No alarm on Doc's face this time!

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 04/01/2008 : 16:02 Posted - 04/01/2008 : 16:02

Neville, he wasn't alarmed, as I panned over to him he was yawning!

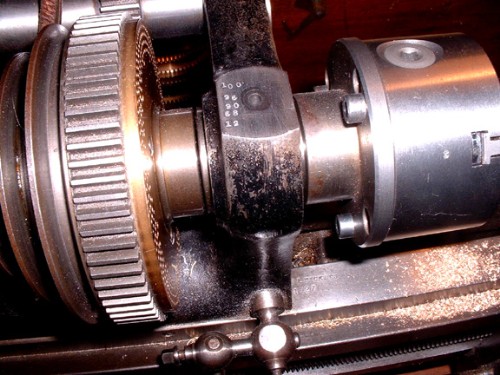

I have had my usual Friday domesticity kick, shopping, washing and cooking. I decided this afternoon that I should take one small step back towards the shed.... Something that has annoyed me for a while is the fact that when Johnny built his lathes he didn't bother to do any marking of the number of holes on the division plate in the head because he knew them by heart. I solved the problem on the 1952 lathe a long time ago by putting the numbers on the flat top of the headstock bearing. I did the same for the 1927 lathe this afternoon.

100, 96, 90, 68 and 12. If you think about it, these divisions give you a lot of possibilities without going to the trouble of putting the tangential gear on the end of the headstock mandrel. Only a small thing but it will make life a lot easier.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 04/01/2008 : 16:06 Posted - 04/01/2008 : 16:06

PS. When Johnny built the big lathe in 1962 he only had room for 4 rows on the face of the worm gear so he used 100, 96, 90 and 12.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 06/01/2008 : 16:08 Posted - 06/01/2008 : 16:08

I've struck the first blow.... The movement is out of the clock and I've been doing a bit of research. It's a vienna 2 weight chiming regulator with a porcelain face and an ebonised case. There are perhaps a couple of finials missing off the top of the case but otherwise it is in totally original condition with no damage. It was made by H Endler in Freiburg, Silesia. There is a trademark on the back of the movement that identifies him. He was in business between 1865 and 1890 and from the number on the back, which is quite large, it's probably nearer 1890 than 1870. There is a scratched clockmakers mark in the black laquer at the back of the dial which says it was overhauled and regulated in 1949 by E B (?) Scott. The clock lived in Earby at that time I think but I don't know of a clockmaker by that name. The cause of it stopping is, as I suspected, a broken feather on the pendulum. The movement is filthy and it's quite obvious that what it needs is a complete strip-down, clean and overhaul. I've decided that I'm too inexperienced with clocks to start my clockmaking career on this, it's totally original and quite valuable. I'm going to get Fred Huppach to do it for me. He's a good man and will make s superb job of it. All right, it'll cost but the labourer is worthy of his hire and I think too much of the clock to take any risks with it..... So, tomorrow, I'll go and see Fred. By the way, I found one exactly the same on a website except that it was not ebonised. It was not for sale. I found another one dated 1880 in a non-ebonised case on an antiques website in the US and it is priced at $2000. Top wack I suspect, I reckon that in perfect nick it will be worth at least £600. Well worth spending a bit on it.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 07/01/2008 : 17:14 Posted - 07/01/2008 : 17:14

One thing I didn't mention yesterday is that someone must have got fed up of hearing the clock chime at some time because they've taken the hammer off..... I shall get Fred to fit another.

I must be getting over post-engine depression because I have been busy all day. Fred isn't open until Wednesday so I theought I'd do some of the mundane jobs to help save him time. The first thing I did was take the fingers off and clean up the porcelain dial with a very old soft scotch pad and water. It has come up a treat and there is only one small chip out of the enamel which I suspect is a blowhole, certainly not noticeable. The pendulum bob was very dirty and caked with old oil and varnish.

It took a good clean-up with a proprietary brass cleaner which I suspect had some acid in it. I washed the bob afterwards and finished it oiff with 'The Soldiers Friend' polish, 3d a tin and made in Bristol. Brand new and never been opened. I got it in a box of bits at a workshop sale. I suspect it's jeweller's rouge or crocus powder, it did a good job anyway and the bob is clean again.

The other thing I can do to help Fred is get the case cleaned up. There is no damage to it anywhere, just normal wear with 125 years of dusting. A ggod clean is all it needs. However, there was one thing..... I've always wondered what was on the top of the clock, whatver it was it was missing when I got it. Looking at the pics of other Vienna clocks on the web I got a fair idea. The case has full columns up each side but nothing fancy so I decided to make a simple cirved pediment and finish it off with a turned brass finial. It just so happened that I had one in the treasure chest. Here it is after spinning it up in the lathe and fitting it in a threaded hole on the pediment. I think it's just about the right proportions, indeed, this is probably what it was made for in the first place. I cleaned off all the old glue and broken dowels and rubbed the top down before giving it a coat of matt black paint. The case is ebonised white wood and no finish on the top so this is the right treatment. After sanding the pediment smooth I gave that a coat of matt black as well, it'll get a rub down and a coat of black gloss and will be OK. It'll soon blend in with the rest of the case. Another coat tomorrow, it's sat on the radiator to dry properly.

The wood for the packing case arrived today so that can be started. I also got a piece of 1/2" ply for a base for the compound. This isn't for fancy, just to protect whatever surface it sits on. It has its base now and is sat on the coffee table in the front room, another ornament to dust! So, the worktop in the kitchen is a bit less populated and by the end of the week the engines will be packed and crated up and I can weigh and measure the crate and get some accurate quotations for shipping. All told a good day and a bit of progress. Clock case cleaning tomorrow......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 08/01/2008 : 17:27 Posted - 08/01/2008 : 17:27

The pediment is fitted with dowels which match the holes I drilled in the top of the clock and it has had a coat of gloss paint. It won't be as good a finish as the clock body but will not look out of place. I've cleaned the clock body and done a couple of minor repairs and it's ready for the clock now. I've even remembered to move the screw in the wall down so that the clock will fit in the archive now it is 6" taller.

I've started on the packing case, here are the two ends with carrying handles. I've done the signwriting (?) on the two large sides with the addresses on but of course I'm not showing that..... Off to Fred's tomorrow with the movement. See if I can persuade Ringo to ferry the case round there as it's too big and awkward to carry and then get on with the ppacking case. Don't see why it shouldn't be ready for despatch tomorrow. I can weigh it then and measure it and go out for a carrier.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 09/01/2008 : 09:17 Posted - 09/01/2008 : 09:17

here's the clock case with its new pediment, ready to go to Fred's for a holiday.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 09/01/2008 : 17:33 Posted - 09/01/2008 : 17:33

We're getting there with the packing case. The engines are screwed down to the base of the case and I'm fitting packing struts across the tops of the cylinders to relieve the base fastenung of any sideways strain. By the way, I've sprayed the engines with oil and the plastic encloses them completely. The other engine will get a top strut tomorrow and once the other side goes on there are two other restraints, wood pads under the lid that touch the cylinder tops and two heavy struts between the base of the case and the lid to give it crush strength if anything is stacked on top of it. Once all that is done there isn't much room for them to move even if something catastrophic happened to the case. I know it's belt and braces but I want to do everything I can to make them safe. Paying extra for transporting wood across the world is no problem.

Fred has the clock except for the case. he isn't taking any more clock repairs because he is mowed out with work but I got his wife Freda to have a word with him.... It'll be long term but he's going to do it so the case is back on the wall in the front room waiting for him to give a shout for it. Lots done today...... I can't wait to weigh and measure the case so I can get some quotes. I'm not going for the cheapest, I want the safest.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 09/01/2008 : 19:27 Posted - 09/01/2008 : 19:27

Stanley

Looking fairly impregnable to me, I shall be interested to see who gives you the best price.

Your are pricking my conscience with your Austrian wall clock. I've got my Grandparent's one upstairs that I've been meaning to send out for repair. Even in my childhood, all my Nottingham relatives had one of these on their wall. They often called them Vienna Regulators, although Dad always said a regulator was a special made by a clockmaker for their own use.

We still have three in the family, one with weights that probably has an identical movement to yours, and two later ones with silvered dials and spring movements. All three are missing the top pediment!

Trouble with Grandad's one was that he would never take it to a proper clock specialist. There was always some local bloke who was "good with clocks" mended Ronson lighters and cured cholic in greyhounds! Sort of Midlands equivalent of a witchdoctor for clocks. I intend to get it done properly!

Malcolm

|

Gugger

|

Posted - 09/01/2008 : 20:34 Posted - 09/01/2008 : 20:34

Stanley,

Has the timber of your boxes been treated against the sirex wasp?

Watch out, Australia has some strickt regulations if you dont have papers stating that the timber has been treated you risk that the boxes with the content will be sent back.

Walter

|

panbiker

|

Posted - 09/01/2008 : 21:49 Posted - 09/01/2008 : 21:49

I was intrigued by this Stanley and found this on the web:

http://www.transpak.com/industrylinks/australia.html

I am sure you will check all the requirements, I hope this helps.

Ian  |

Ringo

Site Administrator

3793 Posts

|

|

Posted - 09/01/2008 : 22:20 Posted - 09/01/2008 : 22:20

http://www.pacific-pallets.com/green.htm

|