| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/06/2008 : 07:08 Posted - 26/06/2008 : 07:08

Nothing exciting to report. I am quietly working through the lathe stripping and cleaning as I go. I'm on the last chuck at the moment and the thing that strikes me about the old Cushman and Pratt chucks is how low-geared the scrolls are. There is no wear in either of them and they are as tight as the day they were made. Only thing that's missing is the outside jaws for the Cushman. The thing that strikes me is the fact that Johnny had two 8" SC chucks for the same lathe. This is a real old turner's trick. It means that if a turning job crops up that needs an SC chuck you don't have to disturb the work in hand, you just svrew the chuck off and install the spare. Another parallel matter is that Johnny once said that everyone needed at least two lathes for the same reason. You can have two cuts going at the same time and it saves time setting up by re-chucking. One little surprise for me. I decided to skim the tube plate that you can fit for centering the ends of tubes. No go, it's pot hard steel!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/06/2008 : 17:31 Posted - 26/06/2008 : 17:31

I put a new pulley on the motor roday to bring the lineshaft speed down a bit. I had it far too fast. There was also the small matter of the two pulleys being made for different belts. I had to do some fiddling with the end plummer block but I've got it running on a normal Fenner belt now and it will be a more positive drive. The belt's a bit tight but I think I can get away with it and it'll soon stretch a bit..... If not it's back to the Brammer but a larger size.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 27/06/2008 : 07:23 Posted - 27/06/2008 : 07:23

It's wonderful how a good night's sleep can clarify your mind. I've done the basic job by finding the smaller, correct groove width pulley and I was over-egging the pudding by fitting the solid belt because I was annoyed with myself for not measuring up better in the first place. It's too tight and there is no point putting too much pressure on the front bearing of the motor. The Fenner comes off and is replaced by an 'A' section Brammer as soon as I have done the shopping. I was focussing on the wrong thing, using the Fenner belt. Nowt wrong with the Brammer and a more than adequate drive.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/06/2008 : 07:37 Posted - 28/06/2008 : 07:37

Back to the Brammer, pressure off the bearings and running better and smoother with no belt slip. I ran the four top speeds (no back gear) and mesured the revs. They came out at 160, 328, 556 and 1128. This compares with 216, 306, 479 and 750 on the Harrison 11" lathe. Johnny sized his headstock pulleys to give a wider spread. Crafty old man..... not much you can't turn at 160rpm so very few occasions when you need the back gear. I haven't tried it but I'll bet he did all his screwcutting at 160.

I cleaned the two face plates up and we now have a fully functioning lathe. Nice!

Notice that I have started my oil mark on the wall and the ceiling...... I remember Newton telling me how his mother sauced him when he had Johnny's 1927 lathe set up in the attic at Federation Street in the days when he lived at home. She didn't like the brass chips all over the house either.... In case anyone is wondering, the brass faceplate is a very old fashioned accessory for a lathe. It was used for turning very thin workpieces, you soldered whatver you were working on onto the face of the plate. Often used for engraving clock faces. Apart from the catch plates there is also an old fashioned dog chuck, the forerunner of the larger 4 jaw independent chuck. Pure Holtzappfel.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Gugger

|

Posted - 28/06/2008 : 16:23 Posted - 28/06/2008 : 16:23

Stanley,

If you have to cover the oil marks, I have some wallpaper left from the last job I did in my house.

Walter

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/06/2008 : 18:12 Posted - 28/06/2008 : 18:12

Hee Hee..... It's a badge of honour Walter, shows I oil my chucks.

One or two odd jobs in the house today like varnishing some wood and a large work surface which I use for maps in the bathroom but into the shed after lunch. I cleaned the catch plate up and made it shiny again. Then I had a look at the dog chuck but the thgread on it isn't good so rather than mess about with it I chucked it in the treasure box. I can't see me ever wanting to use it. Then I had a look at the arrangement of gears that Johnny designed and fitted to give power feed to the cross slide. It works by having a worm wheel in permanent mesh with the lead screw and a cone clutch between that drive and the gear train to the cross slide. To make it work you lock the saddle in place on the bed and then lock the taper clutch. When we first found the lathe it was in bits and after I had built it up I got Newton over to have a look at it and when he saw I had found the gears for the power cross feed and installed them on the saddle he told me I was wasting my time as neither he or Johnny ever used it. I took no notice and left them on. Now I have the lathe set up properly I have tried it and of course Newt and Johnny were right. The problem is that the saddle lock isn't positive and the saddle can creep under the influence of the drive. The gearing increased the effoirt to turn the handwheel on the cross slide and so this afternoon I stripped the front of the saddle down and took the gearing off. Good move, the hand wheel on the cross slide is dead easy to turn and smooth as silk. The only way the drive could be made foolproof would be to have an adjustable stop between the saddle and the front face of the headstock and it's just too much of a faff. teatime.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

frankwilk

|

Posted - 28/06/2008 : 19:53 Posted - 28/06/2008 : 19:53

See below

Edited by - frankwilk on 28/06/2008 7:55:19 PM

Frank Wilkinson Once Navy Always Navy  |

frankwilk

|

Posted - 28/06/2008 : 19:54 Posted - 28/06/2008 : 19:54

Stanley did that engine you made arrive safely in Australia ??? I can't remember seeing anything about it

Frank Wilkinson Once Navy Always Navy  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/06/2008 : 07:58 Posted - 29/06/2008 : 07:58

Never sent them Frank. Thanks to Walter I enquired what the import duty would be. They wouldn't state a definite amount but it was going to be about £2000 so the packing case is now the toilet roll store in the bathroom and the engines are sitting in the front room. Janet has seen them and who knows, she might find a way around the problem....... They'll get them eventually but God knows when.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/06/2008 : 08:01 Posted - 29/06/2008 : 08:01

Frank, see page 78 onwards for the full story.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 09/07/2008 : 17:38 Posted - 09/07/2008 : 17:38

You may have noticed I've been absent from the shed for a few days. I have a confession to make..... I made another of my mistakes when I was finishing the 1950 lathe off. I was reaching over the lathe bed in an awkward position to tighten the nuts holding the motor on the slide and cracked a rib. Dead easy to do, just cracked the end of one of my short ribs, they used to call it a click rib. And before you ask, no I didn't go to the doctor, nothing they can do about it other than fill you with pain killers and I don't like them so I kept out of the shed and left it to nature. They take about 12 weeks to heal, twice as long as a break but the initial pain has gone almost and I shall be back in there shortly.

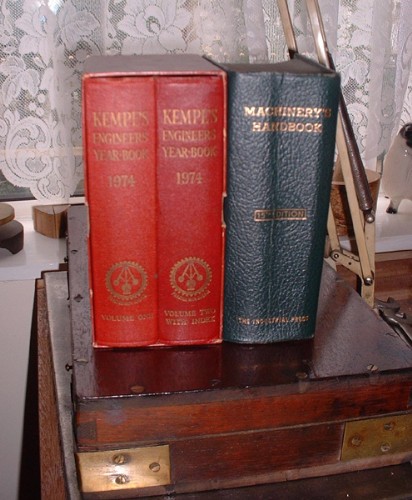

Meanwhile, if you can't get in the shed, here's the next best thing:

Two of my best friends; Kempe's two volumes from 1974 and Machinery's Handbook for 1956. Bit like a cricketing fan browsing through Wisden. If the answer isn't in these two or Molesworth you're in trouble and you'll have to start digging on the shelves. If you haven't got either of these, get Machinery's Handbook, plenty available secondhand and the older ones are best because they have all the old Imperial stuff in them.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

jgb7573

New Member

44 Posts

|

|

Posted - 11/07/2008 : 09:11 Posted - 11/07/2008 : 09:11

Two good books there for when you can't get into the shed. I've just finished Walkers account of the building of the Severn Tunnel, and am about to start on Browne, Fitting and Erecting of Engines. Also good stuff for when you can't get out there. Mind you, I have managed to fix a bench in the workshop this week and started to arrange for a shadow board. In between work, family, house and garden, not bad!

John

JohnB,

Found that horn - gorn!  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 11/07/2008 : 17:34 Posted - 11/07/2008 : 17:34

Ditch garden and work, concentrate on family and shed!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 11/07/2008 : 21:07 Posted - 11/07/2008 : 21:07

Stanley I did warn you to take care weeks ago!

I've been out of the shed for a long time, touch of the "black dog" and domestic matters in general. Jobs are piling up, if only earning a living didn't get in the way.

Months ago I ordered 3 new bookcasaes to replace some old MFI ones that were heading for a Tay-Bridge style disaster. After months of silence from the suppliers, they have suddenly appeared which means frantically clearing the books out (have you any idea the floor space books from just one 3' by 5' bookcase take up?).

I managed to sort it all without injuring myself, but now comes the long-winded bit - putting them all back. I keep discovering things I had forgotten about and there is the temptation to read them....!

I must get in the shed some time, just to keep ahead of the MOT man!

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 12/07/2008 : 06:43 Posted - 12/07/2008 : 06:43

Yes, I know, but you know the problem, in my head I'm as strong as I was 40 years ago...... Did a small job on the 1927 lathe in the front room. In the interests of keeping to the original I put round leather belting on the two drives but was annoyed by the motor belt slipping a bit. So I replaced it with a 'V' belt last night. Better drive, no fastener click and the old motor runs more quietly. I haven't done anyting serious on the 1950 lathe yet beyond squaring the ends up on stubs out of the scrap box to get me tuned in to using it. One trap is that the traverse handle for the bed runs the opposite way on the 1927 lathe to the 1950, you have to get your brain in gear bfore you wind the saddle away with the chuck running! I used to have a similar problem when I was running the Harrison with the Wilson lathe. The traverse and cross slide wheels were opposite hand on the Wilson and it was all too easy to wind the tool in istead of traversing if you went from one to the other.

Books, I know the problem well. I can remember what two walls full looked like when I flitted into this house. Still rearranging them but not often I lose one now....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |