| Author |

Topic Topic  |

|

karlelden

|

Posted -

03/01/2007

:

15:06 Posted -

03/01/2007

:

15:06

|

|

I'm just beginning to explore this amazing website, and I put "engine" in your search engine and came up with a BUNCH of hits. I started looking around and decided you people are living in the tall corn compared with us in the US. I have maybe 2 decent larger stationary steam engines to look at in a 200 mile radius. At first glance I thought you were in Hawg Heaven. Looked to me like you had MANY significant preserved engines.

However, I then came upon a picture of the Leigh Mill engine, went to Google to check it out, and came up with this from 1995:

http://www.britarch.ac.uk/ba/ba1/ba1news.html

Down past the news about how skulls used to contain brains is this bit of stuff about the Leigh Mill:

"A rare example of an intact traditional spinning-mill, near Wigan in Greater Manchester, is under threat from a proposal to remove the original mill engine from the building.

The early 20th century, listed Grade II* Leigh Mill, with its surviving engine house and engine, is still used as a factory and now manufactures carpets. The owners, Leigh Spinners Ltd, applied for permission to remove the original engine to create more storage space.

Their application went to public inquiry in November, and John Gummer, the Environment Secretary, is expected to decide the matter later this year.

Speaking at the inquiry on behalf of the CBA, Ron Fitzgerald, an industrial archaeologist, said the importance of the 1923 engine was enhanced by its `extremely rare' survival in its original context. `Out of 238 listed mills in the north, only six engines survive,' he said. "

So, does anyone know if this is true? Are there only 6 surviving mill engines? And does anyone know what finally happened to this engine in the Leigh Mill?

Karl

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 27/12/2007 : 06:39 Posted - 27/12/2007 : 06:39

Only engines I have ever come across with common cylinder covers were the Willans inverted verticals. I.ve never seen the book.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 27/12/2007 : 22:09 Posted - 27/12/2007 : 22:09

Hi Chaps

Been away over Christmas doing the family bit, so I've only had a brief look at OGFB via dial-up (how did I ever manage without Broadband!).

Not heard of this book, but the "Recent" bit in the title gives it away as, presumably, a reprint of a period book. The bit about the Pollit engine with the common cylinder cover implies a twin horizontal triple with the low pressure on the other side. Pollits did build a few triples, but the only one I can trace has a conventional set-up. A common cylinder cover would pose some interesting problems for the man who erected the engine!

As far as I know, there are two "3" rod tandems still in working order, and a conventional tandem which is now in a museum store, (that one was never a working mill engine, it was made for a college heat lab). Bits of another "3" rod survive on display in a museum near Sheffield.

There is also a nice drop valve cross-compound which survives in exile a long way from Yorkshire. When I get a chance, I'll post some pics of that one.

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/12/2007 : 08:38 Posted - 28/12/2007 : 08:38

My mate Robert has one in store that came out of Slaithwaite.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 28/12/2007 : 19:29 Posted - 28/12/2007 : 19:29

Stanley

You made me think there, I remember that Tony Marchington, one time multi-millionaire, and owner of Flying Scotsman, bought a dismantled mill engine, said to be a Pollit. It was supposed to be going into a proposed steam museum at the old wire works at Ambergate in Derbyshire. After he went bankrupt, all his steam stuff was sold at auction. I also remember a "Pollit on pallets" advertised in "Old Glory" magazine for what seemed at the time to be strong money. If this is all the same engine, I am glad to know that she is now in good hands. I presume that this is the 1910-built 250 hp tandem from Crowthers of Slaithwaite.

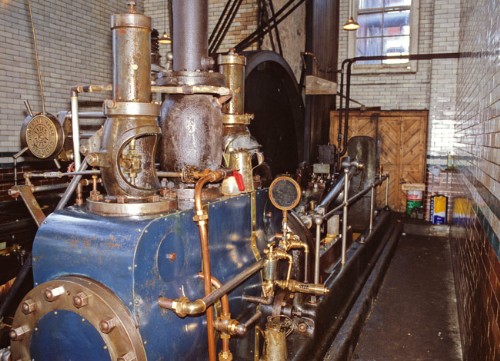

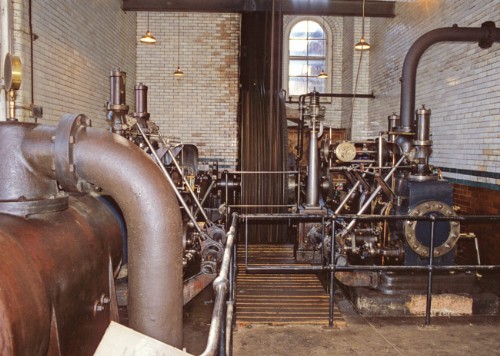

Continuing the Pollit theme, here is the home of what is (probably) the sole surviving Pollit cross-compound.

Coldharbour Mill in Devon is a combined spinning and weaving mill which still produces cloth as a functioning museum. They have had their share of ups and downs (including boiler problems) but it is a very pleasant spot to break a holiday journey to the West Country, being only 3 miles from Junction 27 on the M5.

Tourist info at: http://coldharbourmill.org.uk/

It has always used water power but with steam in reserve, latterly using this 1907 Pollit cross-compound

On my last visit, when these photos were taken, she was in steam but needed a bit of care and attention. There was also a heap of beam engine bits in the mill yard. I gather they have now put the beam engine into the old empty beam engine house, and both engines look a bit smarter.

A long way from Barlick, but worth a visit if you are down that way.

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/12/2007 : 07:17 Posted - 29/12/2007 : 07:17

The Crowther engine is the one. Robert took it out himself and the Belliss at the same time. The Science Museum asked me to go to Coldharbour Mill many years ago to advise them on the plant so I went down there for a couple of days. They were renovating the oldest boiler at the time. They asked advice about the engine and I remember the first thing I said was get a stop motion on it. If I remember rightly there was no overspeed motion. Looks a lot cleaner than when I saw it, didn't even realise that the walls were tiled!

By the way, using steam or oil engine with a water wheel was a common strategy because water wheels are almost impossible to govern accurately. The full power was taken out of the wheel and topped up with the steam engine so the engine governor was regulating the shaft speed. very succesful ploy as the variation in the water wheel was very slow and the engine governor was fast enough to counteract it.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 29/12/2007 : 18:59 Posted - 29/12/2007 : 18:59

Since Robert Arum's engine came direct from Crowthers, then the other engines I remember may be still about. George W. said that Politts made as many engines as anyone, so I suppose a high survival rate shouldn't be a surprise.

Looks like they took your advice at Coldharbour Stanley, the Tates springbox is prominent on the stop valve. From what I can remember, they had a pair of fair-sized water wheels, and plenty of water from the Blackdown Hills. A lovely spot, just a pity they couldn't save the Culm Valley Branch Railway that passed behind the mill. It was one of the last rural branch lines in the area and lasted until the late 1960's just on milk traffic from a depot at the end of the line at Hemyock. Incidentally, Coldharbour was another mill, like Watkinsons at Holmfirth, who founded their business on khaki material. Foxes supplied material for puttees all over the old Empire almost until the end!

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/12/2007 : 06:13 Posted - 30/12/2007 : 06:13

The Tate's motion might have been on it when I was there. I used to discount them, they were so unreliable. They only reacted (if at all) to an engine stop button being hit in the mill. If I remember rightly, the thing that I warned them against was the fact that there was no overspeed/underspeed catch on the governor linkage. far better and more reliable than the Tate's motion as it reacted immediately to any aberrent event in the governor linkage as long as the engineer had remembered to knock the catch back in after starting. Newton said that was what caused the Bishop House smash in Burnley, the engineer hadn't put the peg in after he started the engine. N kept quiet about it because the engineer was in such a bad way. I used to test the governor mounted Tates motion at Bancroft and it never worked properly. If someone smashed a glass it rang the alarm bell but the hammer wasn't heavy enough to knock the catch out in the linkage.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

karlelden

|

Posted - 15/01/2008 : 02:24 Posted - 15/01/2008 : 02:24

Been browsing around and just stumbled upon the Photobucket of a man from England. Look at these pictures of a Pollit engine:

http://i3.photobucket.com/albums/y54/Asquith1/Pollitt06.jpg

http://i3.photobucket.com/albums/y54/Asquith1/Pollitt07.jpg

http://i3.photobucket.com/albums/y54/Asquith1/Pollitt03.jpg

And the tell-tale "3 rod" setup:

http://i3.photobucket.com/albums/y54/Asquith1/Pollitt02.jpg

And a short video clip:

http://s3.photobucket.com/albums/y54/Asquith1/?action=view¤t=Video1001.flv

This man has MANY PAGES of great pictures!!! I'll be lost in that collection for a long while!

OOPS!! In browsing through this man's collection, I found the very picture of the E-road engine that I have and posted on this forum some time ago:

http://i3.photobucket.com/albums/y54/Asquith1/Dscn1245.jpg

Obviously, I need to be careful to look for credits before I post things that come in my email. Often I get pictures from here and there and save them without thinking of possible copyright infringements. I need to track down this man and apologize!!

Edited by - karlelden on 15/01/2008 03:16:29 AM

Karl Elden |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 15/01/2008 : 12:02 Posted - 15/01/2008 : 12:02

I just opened the last one...... I know it well!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Bodger

|

Posted - 15/01/2008 : 15:27 Posted - 15/01/2008 : 15:27

Hi guys,"Asquith" is a member on the website, www.practicalmachinist.com

The site is an American one, but has some interesting forums, Asquith is usually a contributor on the antique machinery section, this includes old machine tools and steam power, well worth a look.

Stanley, he quoted yours regarding the try out of the steam engine for Coates, Tony

"You can only make as well as you can measure"

Joseph Whitworth

|

softsuvner

|

Posted - 15/01/2008 : 16:56 Posted - 15/01/2008 : 16:56

The Pollit 3 rod pictured, is the engine shown earlier in this thread at Washpit Mills, Holmfirth. It now resides at Markham Grange Steam Museum. I believe they've done some research and found that maroon was the original colour. All credit to them, she's running again.

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 15/01/2008 : 18:22 Posted - 15/01/2008 : 18:22

Bodge, I found the link after a bit of searching. I've registered with them and will have a word with Asquith.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Asquith

New Member

23 Posts

|

|

Posted - 15/01/2008 : 23:08 Posted - 15/01/2008 : 23:08

Karl Elden has tipped me off about this forum, and I'm now honoured to be amongst this august company.

There's clearly an amazing wealth of knowledge and experience here. Look, I'm from Lancashire myself originally so I know all these fine words butter no parsnips, so I hope that a curt nod will suffice (there should be suitable icon here, of a bloke who looks like Uncle Mort, animated with a barely perceptible nod of the head).

I can't offer much in the way of experience with steam engines (not the reciprocating ones, anyway), but if anyone's after any specific information, I have occasional access to copies of 'The Engineer' and 'Engineering' going back to 1856. If only the indexes didn't run to thousands of pages.....

If the Stars and Stripes is still waving on the left, it is due to finger trouble. I inadvertently scrolled off the United Kingdom when registering. Could have easily been Uzbekistan. I'll try to change it, but it keeps rejecting me.

Edited by - Asquith on 15/01/2008 23:20:20

|

karlelden

|

Posted - 16/01/2008 : 05:07 Posted - 16/01/2008 : 05:07

Well, this all turned out well. Thank you, Asquith, for the personal email and for being so gracious about my use of your pictures without credits. I may have gotten them from my older brother in the first place, and he has since passed on, so there you are.

Those certainly are some sweet pictures of a unique engine. Thank you very much!

Karl Elden |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 16/01/2008 : 07:48 Posted - 16/01/2008 : 07:48

John, welcome to the site. I registered on PM to thank you for digging the Eroad stuff out but that was on my old blog which is just about defunct now, I am so busy with OG and other things. Have a look at 'Shed Culture' the SG transcripts in the Lancashire textile Project, the Newton Pickles tapes in the same place or simp[ly use the forum search at the top of the page, it's very fast and accurate since Doc re-programmed us and put the site on a dedicated server. Much to interest you I promise.

On another matter, I noticed in one of your topics on rolling mills there was a comment on the fact that the pinion caps on the roll stand were held by cotters and someone said they didn't think they would need to take them off very often. Whilst waiting at the end of the slab mill at Llanwern for an eight ton lump for delivery in Manchester(in the days when I was on the tramp, wagon driving) we were held up when one of the rolls cracked. The crane came flying down the shed chased by a wagon full of tackle and fitters and they put a spare roll in (it was laid near the roll stand ready) in less than half an hour. I reckon they used cotters to speed the operation up. They'd want as little delay as possible so the ingots in the soaking pits wouldn't be the wrong temperature. I remember being very impressed by the speed with which they tackled a major job. I talked to one of the fitters and he said it was quite a common occurence. He also told me the rolls were turned barrel shape because daft as it looked, they bent when they were rolling heavy metal. On the big slab mill I saw them using brushwood to blast the scale off as well. Proper fireworks display.

Most i,pressive thing I ever saw in a steelworks was at Dormans at Middlesborough. They were pouring steel into ingot moulds on the floor and the cock on the bottom of the ladle had stuck open so as the crane-driver swung the ladle to the next mould the steel was hitting the sand floor and exploding. Great showerrs of molten metal flying all over and the men on the gantry just turned their backs and let the gobs of steel bounce off them. This was in the 1950's and most of them were just wearing old sports coats and flat hats. Hard men! Can you imagine what Elfin Safety would say about that nowadays!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |