| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 31/05/2007 : 17:32 Posted - 31/05/2007 : 17:32

It did cross my mind Belle that I am the most picture intensive bloke on the site..... I made another leadscrew today and got exactly the same result. I have retired for a rethink, it isn't the torsion it's an inbuilt fault of the die when used on long threads. I retired for a rethink and did some odd jobs. I shall return to the fray tomorrow and I promise there will be a straight leadscrew! Did you like the sculpture? I love making metal into the shape I want, that's real control!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

belle

|

Posted - 31/05/2007 : 19:36 Posted - 31/05/2007 : 19:36

It was interesting, i like my sculpture rounded....or human shaped....love the angel of the north, but I saw a henry Moore sculpture recently that moved me to tears, and that hasn't happened before!

What percentage of time is spent thinking, when doing your experiments in the shed. i noticed you quite often go away and have a think...some thing i like to do when I'm tackling a sticky problem...it's as important to be away thinking as it is to be at the bench doing wouldn't you say?

Life is what you make it |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/06/2007 : 07:18 Posted - 01/06/2007 : 07:18

Spot on Belle. I've always done it, go and have a pipe and a pot of tea and let your mind roam. I tend to start a train of thought when I go to bed and then drift off to sleep. When I wake up I have a clue to the answer. I reckon my brain goes on working and searches the memory banks while I am asleep. A coat of thinking over saves a lot of time. As Holmes used to say 'a three pipe problem'. The sculpture bit goes back to my need for control.... I love imposing my will on intractable materials. Try cutting slots in half inch boiler quality plate, it's a miracle when you think about it. Same thing applies to lots of jobs, take the steeplejacks... any normal person with no experience would say that the jobs they do are impossible.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

belle

|

Posted - 01/06/2007 : 09:24 Posted - 01/06/2007 : 09:24

It's funny how many people are motivated to do extraordinary things, just by somone telling them it's impossible! One of my kids got to grade 8 on the violin because i said in a fit of exhasperation one night when they were learning the instrument, " Put it away, will you ever be able to play to that thing!!?" Anyone who has ever heard the repetitive scraping of three notes, that initiates a beginner into violin, will be able to sympathise with me!

Life is what you make it |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/06/2007 : 13:58 Posted - 01/06/2007 : 13:58

The only reason I got the job of doing Ellenroad engine was because it was mission impossible......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

belle

|

Posted - 01/06/2007 : 19:22 Posted - 01/06/2007 : 19:22

Never, say "never"! Eh?

Life is what you make it |

softsuvner

|

Posted - 01/06/2007 : 23:43 Posted - 01/06/2007 : 23:43

Stanley

Loved the wobbly leadscrew! Glad to see that even engineers have the trouble that bodgers like me (I'm the black sheep from a family of engineers) have with silver steel. Got the gear for screwcutting but, that is yet another thing that I propose to leave until I retire. I get by with that Godsend of the cack-handed - the tailstock die holder.

My next project is two stand bolts for a heavy pre-war bike, can't get EN16 hexagon so will probably start with a stud threaded at each end from rod stock. This will take a lot of thought over roll-ups and cups of tea, good job I don't do it for a living, and I'm not brave enough to post photos of the failures either - those secrets are between me and the scrap box!

Suspect our ancestors might have made the leadscrew out of something easier and then heat treated it with their patent mixtures of cows feet etc!.

Cheers

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 02/06/2007 : 06:45 Posted - 02/06/2007 : 06:45

Malcolm, you're right, I was aiming for perfection and using the wrong material. Where I slipped up both times was in not finishing the leadscrew by simple screwcutting. I've been hampered by the workmen popping in and out on the snagging jobs. I have a chance to attack it again today and I think I might crack it. I always post my mistakes, if I didn't it would give people the idea I am an expert..... Far from it, I can do the most stup[id things at times, generally ruining something I have spent hours working on. Character forming or masochism.......? The cure for the problem would be to make a die holder with an extension on it long enough to stop the die wandering. If you look at a set of pipe-threading tackle they always have a short guide-piece on the nose of the die even for short cuts.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Ringo

Site Administrator

3793 Posts

|

|

Posted - 02/06/2007 : 12:38 Posted - 02/06/2007 : 12:38

Like Malcolm says the original would have been roughed out, hardened and then if a tight limit was needed I would have thought it would have been put through a Thread Grinder.

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 03/06/2007 : 05:42 Posted - 03/06/2007 : 05:42

You'r right of course Rick but thread-grinding is beyond my capacity. I'll fight it using the tools I have and just ditch the silver steel..... too tough for such a small diameter. I got diverted yesterday into tidying the back yard up, shed roofing and painting. We approach a tidy backyard!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 08/06/2007 : 07:10 Posted - 08/06/2007 : 07:10

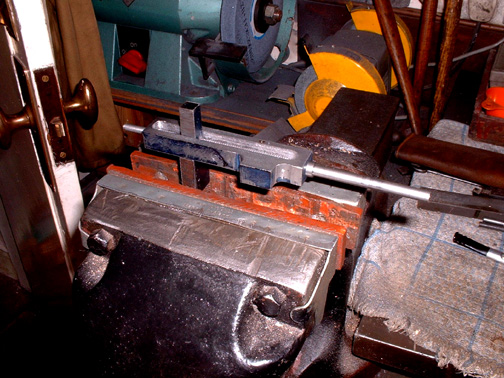

I've been hampered by workmen but got back into the shed yesterday. The leadscrew is OK now, third attempt. I've started chopping the leadnut out of 3/4 inch plate. It has to be steel because it incorporates the tool holder. If Andy is watching this, give me a ring because I want to know what speed you run these cutter at, I can't find any info anywhere!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 08/06/2007 : 12:23 Posted - 08/06/2007 : 12:23

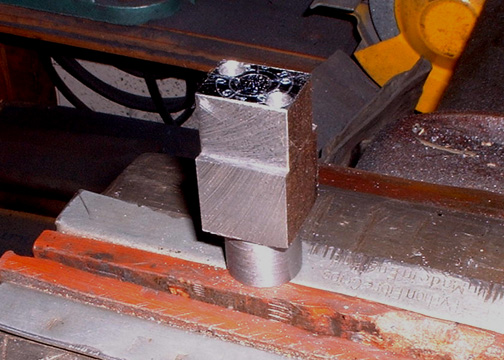

We have a roughed out leadnut running on the screw. Now I need to turn it into a thing of utility and beauty!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 09/06/2007 : 18:13 Posted - 09/06/2007 : 18:13

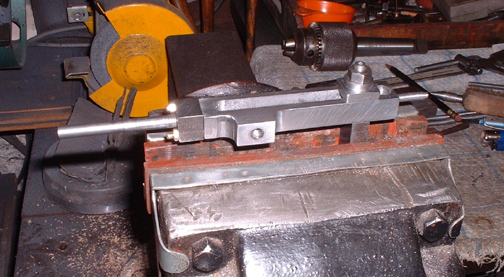

The leadnut has its cap and locking nut.

This is the cap that will go on the end to restrain the leadscrew and carry the adjusting knob. Hard to see because of the blueing but it has a scale engraved on the end divided into 5 segments because one turn of the screw is fifty thou. A day of small fiddly fitting jobs, I love it..... no hard work, just careful metal shaping using just about every machine in the shop. The two jaw chuck and the SC four jaw on the Harrison were used. The horizontal miller cuts the metal and keeps everything square and the 1927 lathe with the dividing head was just right for the scale. That's why the spare end of the cap is turned round. I've drilled for the 5BA countersunk screws that will fasten it and tomorrow it needs cutting off to length and polishing up.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 10/06/2007 : 17:00 Posted - 10/06/2007 : 17:00

More has been done...... Restraining cap is fitted but not reduced to conform with the frame. You'll notice the threaded hole for the driving spindle, looks fine but when I fitted the spindle it's not square. I expected that and there is room to re-tap to 3/8 whit, insert a piece of stock and turn it to size in situ, it's got to be square then! I had a bed moment when the 5 BA tap broke in the hole. I was only in a couple of threads. No way I could get it out so I drove it into the bottom of the hole and re-tapped both holes 4BA. Two brass studs fitted and we are in business. Only way I know to get broken taps out is spark erosion and I'm not fit up for that......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Ringo

Site Administrator

3793 Posts

|

|

Posted - 10/06/2007 : 17:04 Posted - 10/06/2007 : 17:04

Only way I know to get broken taps out is spark erosion and I'm not fit up for that......

If you need any taps sparking out, let me know as I have access to one at work.

|