| Author |

Topic Topic  |

|

karlelden

|

Posted -

03/01/2007

:

15:06 Posted -

03/01/2007

:

15:06

|

|

I'm just beginning to explore this amazing website, and I put "engine" in your search engine and came up with a BUNCH of hits. I started looking around and decided you people are living in the tall corn compared with us in the US. I have maybe 2 decent larger stationary steam engines to look at in a 200 mile radius. At first glance I thought you were in Hawg Heaven. Looked to me like you had MANY significant preserved engines.

However, I then came upon a picture of the Leigh Mill engine, went to Google to check it out, and came up with this from 1995:

http://www.britarch.ac.uk/ba/ba1/ba1news.html

Down past the news about how skulls used to contain brains is this bit of stuff about the Leigh Mill:

"A rare example of an intact traditional spinning-mill, near Wigan in Greater Manchester, is under threat from a proposal to remove the original mill engine from the building.

The early 20th century, listed Grade II* Leigh Mill, with its surviving engine house and engine, is still used as a factory and now manufactures carpets. The owners, Leigh Spinners Ltd, applied for permission to remove the original engine to create more storage space.

Their application went to public inquiry in November, and John Gummer, the Environment Secretary, is expected to decide the matter later this year.

Speaking at the inquiry on behalf of the CBA, Ron Fitzgerald, an industrial archaeologist, said the importance of the 1923 engine was enhanced by its `extremely rare' survival in its original context. `Out of 238 listed mills in the north, only six engines survive,' he said. "

So, does anyone know if this is true? Are there only 6 surviving mill engines? And does anyone know what finally happened to this engine in the Leigh Mill?

Karl

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/11/2007 : 07:35 Posted - 28/11/2007 : 07:35

How long have they had it? if it's a recent aquisition it's the engine taken out of Cudworth Brothers at Baitings Mill Norden. I know it was taken out for export.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 28/11/2007 : 10:05 Posted - 28/11/2007 : 10:05

Stanley

I'm sure that it is the Stott engine from Norden. Shame that we couldn't save it in this country, but at least it is in one piece and it looks like they have made a nice job of setting her up.

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/11/2007 : 22:55 Posted - 28/11/2007 : 22:55

Thought it was. Nice little engine and a good set-up as well. Very small for the work it did. It was working hard most of its life.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

oldiron

New Member

9 Posts

|

|

Posted - 29/11/2007 : 21:39 Posted - 29/11/2007 : 21:39

Stanley,

It is indeed the Stott engine from Cudsworths and was moved here about 5 years ago. I'm also suprised it would be so powerful given the size. We were able to find some of the original documents, bill of sale (for 610 pounds) , etc. after a bit of detective work.

Tale a look at http://www3.museumofmaking.org/dbtw-wpd/machine_mary.htm for some of the history and additional pictures and information.

Anything you or anyone else here can add would be very interesting.

|

softsuvner

|

Posted - 29/11/2007 : 23:57 Posted - 29/11/2007 : 23:57

Had a quick look at the site, very impressive

Can't add a great deal about the engine.

You may already know this, but, her last job at Cudworth Brothers was as a standby power driving an old BTH alternator providing 3 phase power at 400 volts. In the early 1970's there was a period of industrial strife in the UK and non-essential firms were restricted to using mains electric power on only 3 days of the working week. A number of firms who still had steam in reserve were able to keep full production going (if they had the coal in stock). A chap who visted this engine in 1980 was told that this period was the last time she was regularly worked.

I sure that Stanley can shed more light on what we over here term the "infamous Heath 3 day week!"

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/11/2007 : 06:49 Posted - 30/11/2007 : 06:49

You're right Malcolm. At Bancroft we kept going 5 days a week by burning coal stocks, I had 300 tons up the yard. We were an object of curiosity in the town for this reason but funnily enough the press never got hold of it. A great advertisement for having an independent prime mover.

Here's Horace Thornton talking about running Victoria in Earby at the same time:

R- About sixty ton I think in winter time, perhaps more. But they had a boiler man on that hadn't much idea. Now, the biggest change in the boiler house was when Tommy Almond come down. Tommy…..? R- Tommy Almond, he worked for Brown and Pickles. Almond. (150) [Newton told me that they had to have all three boilers blowing off with full fires and water right to the top nut on the gauges in order to start the engine and cope with the load] R- Almond, and they were without boiler man so they sent him down. And he could get steam out of stones could Tommy Almond. I never saw anything like him. Charlie Scullthorpe left and went to the Armoride, a lot more money and I suppose better conditions. And they got Billy Lindsay on, he came from Gargrave. He said he was a boiler man but they made about as much steam at Gargrave as if for brewing tea. Well, having to come on to a thing like this, oh it was horse work. And I were no boiler man and my mate weren’t, not same as Almond were. The only thing that Tommy Almond got dirty were his breeches behind, he were really a marvel. he were. It was amazing, he never used to get a sweat on. Well it used to be running down off us, out of us pants bottom, really, were the sweat. And that’s the difference between one that knew his job and one that didn’t. It’s all right throwing coal on and even more coal but that’s not the way to raise steam. Because he was just using the same stuff that Billy Lindsay had been using and as soon as we started up you could watch the gauge and it were just going down and down. And we’d to go down into the boiler house and three of us wiring in to get the steam back up again. And then we’d leave him, [boilers] right, blowing (200) off and then down and down and down. I tell you, I could write a book about the experiences in there. That’s what we are doing Horace. R- But Tommy Almond were good, he were good on boilers, but he were nothing on anything else, he weren’t. But he had two lads, worked somewhere in Barnoldswick and he’d been in a public house one day and getten fresh I think, and him being, bragging about being down here, and telling he were going to get his two lads in. He said “I’m going to have yon two buggers out and get me own lads in.” So we thought well, we’ve to be ready for moving before he moved us. But I will give him his due, he were good on boilers, he were. Oh it, we used to go in and oh what struggles we had. When the steam were down and you were fighting to get it back up and get the engine going. Then happen about an hour and down again, all Lindsay could do was open the door and look in. Oh he were nowt! (250) And the rubbish we got! When there were a right coal shortage we got a lot of slurry. All it were was breeze, they called it slurry. It’s supposed to have been washed off coal, it were nothing but dirt. And the first day it came, mixing it with coal, coal and this slurry together. We did ever so fair, managed to fiddle the day out and went home and when Charlie Scullthorpe came up at morning to get the steam up, it were one solid mass, set everywhere this slurry, it were just same as if we’d filled the pipes with concrete you know, right up into the chamber above. Everywhere solid, you never saw such a pantomime. [The slurry had set in the large pies which let the coal down from the overhead bunker to the hoppers on the stokers. These would be shut off at the boiler when they burned off at night and had set in the pipes, blocking them.] We got it cleared and got going, a man to each boiler but when it were going on there were no flame. The only thing that came off it were just a blue light, just flickering, a black mass and just flickering. So the job soon stopped, there’d to be no more slurry. (300) So the next move, word comes through there were no coal for us, we could have some open cast but it were in big lumps. [what Horace is describing here is similar to that described by Newton Pickles on Tape 78/AG/03 when he and Harry Crabtree were trying to fire Clough Mill on American Lend Lease coal in 1946. The date is right as well. This was brown coal and very poor. I burnt some at Bancroft in 1976 when we got to the back of the stock pile, it had been there for thirty years. It was terrible coal.]And they brought some big loads from open cast workings, big lorries were coming and tipping it in the yard outside. And you know what ironstone’s like? Well brown, that were all it were like, it wasn’t black same as coal. Some of it were but the main were this brown stuff. And people everywhere in Earby were short of coal and the first day when these loads come and were tipped in the open yard they were “Can we have a bit of coal?” “Aye, go on, help yourself.” And George Shuttleworth, one of the tenants, “Could he have some?” So we put some in a sack and put it in the boot of his car and he brought it back the next morning! Because we knew what we were using, using on the boilers, it’d hardly boil a kettle. We had to break it right small, it came in big cobs and we’d a sledge hammer apiece. There were a man to each boiler and they were tipping it in front of the boilers, and you were breaking it up and then throwing it on. And all it did were change colour. It went on, black and brown and it just went to white. It didn’t go any less, it were the same lumps you raked out. I know one afternoon after that come we cleaned out every boiler seventeen times. It were just a matter of throwing it on and it (350) changed colour. Of course the mill were stopped, just everything stopped, you had to struggle on getting steam up and get going again. And all the lot went on like that just as though there was a hole in the bottom of the boilers. My God, summer time and cleaning out seventeen times! You just got so that, do you know, that day, when it come to night I couldn’t lift my arms up. By Gum! So that finished the open cast, anybody that got any brought it back, glad to see the end of it. But it were just brown, main of it were just brown and you’d a job to break it. My goodness!

I've some pics of the engine at Norden..... I'll have a furtle.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/11/2007 : 09:09 Posted - 30/11/2007 : 09:09

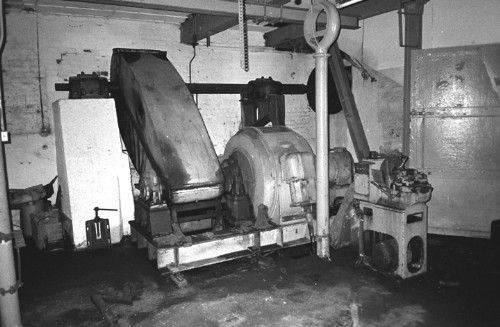

Furtle in progress..... I did some pics at Baitings in 1991 when Cudworths were looking for funding as a heritage site and gave them to them. I also sent a set to English Heritage because they were telling the world that Queen Street Mill was the only steam driven weaving shed left. EH just thanked me for the pics, Cudworths never got any funding and in February 2000 Robert Aram, knowing I was hard up, paid my wage for a day to go and do the pics of the last weaving shed demolition. So the pic below in the weaving shed is historic. Lots more to scan but here are two done in 2000 and I think the engine was being dismantled at that time for its sea trip.

The funny thing about these pics is that because it was a rush job I had no Tri-X and I had made up my mind that it wasn't going to be colour so I had to use HP3 as it was all I could get. Not as good as Tri-X, not as forgiving in low light and this means the pics are a lot more gloomy. However, from what I've seen so far, they're OK. These pics can never be done again unless the unthinkable happens and Queen Street is scrapped. Very interesting for me doing the pics, the end of the line, I had run them and scrapped them and this was the last one.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 01/12/2007 : 00:18 Posted - 01/12/2007 : 00:18

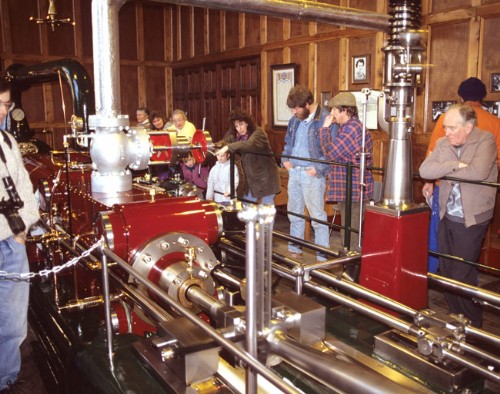

Emotive and unrepeatable pictures indeed. I thought you might be interested in couple of pictures that show a different engine in that limbo between work and preservation, they also testify to Stanley's dictum that it is the man on the ground who matters.

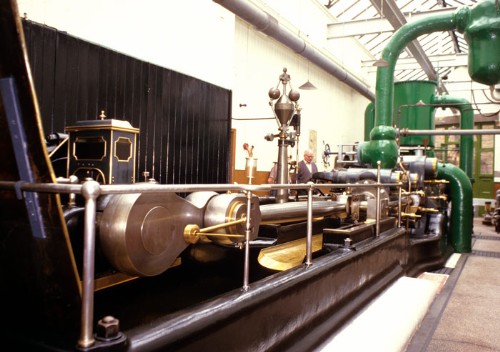

This is the lovely 500 hp Pollit tandem from Washpit Mills, latterly the weaving shed of James Watkinsons who made the first wool-dyed khaki for the British Army. When the engine finished in 1980, her last tenter, Herbert White, was allowed to run the engine for an hour every Friday Dinner for himself, the black cat that lived in the engine room, and anyone else who cared to drop in.

This lasted for 15 years until they had to change the boiler, the new one couldn't cope with the engine. After Herbert died in 1997, the owners gave the engine to Markham Grange Museum near Doncaster. All credit to them, she can still be seen running there, but I do treasure my photos and memories of her in her original setting.

Without Herbert's care and interest, I doubt this engine would have survived.

Incidentally, this mill was a slightly odd set up, the weaving shed and engine house were cantilevered over a stream which, Herbert thought, was probably why they chose this design of engine. The Pollit "3 rod" was a short engine, with an engine-room condensor and high framing which reached around the exhaust valves. The boarded flywheel and rope race were separated from the engine by the matchboard wall seen behind Herbert and his mate.

Malcolm

|

oldiron

New Member

9 Posts

|

|

Posted - 01/12/2007 : 05:42 Posted - 01/12/2007 : 05:42

Thanks for the info and pics Stanley. Would be interested in anything else the furtling unearths.

Another question: what would have been the average working day (i.e. how many hours) for this kind of engine in normal use? I'm trying to estimate the total running hours she has seen. Also, typically what would have been the running speed?

|

oldiron

New Member

9 Posts

|

|

Posted - 01/12/2007 : 05:48 Posted - 01/12/2007 : 05:48

Malcolm, I wasn't aware that she ran a generator at the end. Actually that's interesting as it would be a good way to put a bit of a load on if we get her running on steam. I would guess that something around 50 KW would be enough to make a difference.

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/12/2007 : 06:52 Posted - 01/12/2007 : 06:52

Alan, I mailed Ian at the museum last night and sent him some pics. I'll do a CD fore him when I've scanned them all in. I've done some digging for you in Arthur Robert's Black Book. [I was given a pcopy of this and Arthur and his mates travelled all over the North of England in the 1950s/60s collecting engine details. I must transcribe the hanwritten notes and inex them..... Generally very accurate. His address in the front of the book is A S Roberts, 15 Pasture Crescent, Chapel Allerton, Leeds 7.]

Here's his entry:

R Cudworth, Norden, Rochdale. Named Mary. Engineer W Dobson. 250hp tandem compound by SS Stott 1895. 12 1/2" HP. 24" LP. 3ft stroke. 140psi. Right hand. 68rpm. 14 ft plain flywheel. Corliss HP, Slide LP. Horizontal condenser behind rear LP cylinder. Rope drive, 6 ropes, outside engine room. Lumb Governor. [Lumbs of Elland]

Usual hours, no shift working, 7am to 5.30 pm with breakfast and dinner breaks, say 9 hours a day. Night shifts were very unusual but post WW2 when production was needed many small weaving sheds ran a 'moonlight' or 'housewive's' shift. 6pm to 10pm.

Alan, keep note of all this and convey it to Ian, I take it you have an interest ion the engine?

Malcolm, I looked up Washpit for you:

Washpit, Holmfirth. Engineer Mr Lodge. 600hp tandem compound engine. Pollitt and Wigzel, 1909. 18" HP. 35" LP. 4ft stroke. 180psi, all Corliss valves, 80rpm. 16ft flywheel, 18 ropes. Three piston rod type. Horizontal condenser behind LP cylinder. Also: ?hp F and Chalmers turbo-alternator. 6000rpm geared to 600rpm d/cd Alternator 3 phase. Exhausts to mill or LPcylinder on engine. Uses YEB supply on off-peak hours.

[SCG note. Washpit was a P&W three rodder, the LP cyl had two outside rods to front of HP. Newton called them 'weekend packing engines' because he reckoned you had to re-pack the stuffing boxes every weekend. I went there once to look at a boiler for REW and the manager took me into the engine house to see the old bloke who looked after it. He told me all about it and went on to say that I should go and see Ellenroad but he said that the bloke that ran it was an ignorant bugger because he wouldn't talk to people but just whistled and polished the engine. As he said this he recognised me and his face went bright red. When the manager realised I was the bloke he nearly died laughing. I told the old bloke I wasn't quite as bad as he thought, after starting at 4am in the morning to get the plant going, I was getting fed up of questions in the afternoon.]

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/12/2007 : 17:20 Posted - 01/12/2007 : 17:20

I've scanned all the Baitings pics. Here is the alternator in 2000. All I want to hear now is some word from the museum at Calgary and they can have their pics.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

oldiron

New Member

9 Posts

|

|

Posted - 01/12/2007 : 18:26 Posted - 01/12/2007 : 18:26

Stanley,

Thanks very much for the research. I'm sure Ian will be delighted to see the pictures. I am the curator of the machine tool collection at the MoM and have a great interest in the engine. What we are trying to do at the MoM is to build a comprehensive collection of machinery and manufacturing motive power from the mid-19th century through the inter-war period. Somewhat uniquely for a museum of this type , we are very fortunate to have a benefactor with the vision, enthusiasm and finacial wherewithal to make this achievable. The reasons for doing this are articulated very well by Ian on the web site. Basically there seems to be a growing neglect of this period of industrial history on the part of the major museums (e.g. London Science Museum, Smithsonian, Henry Ford Museum) in favour of more 'trendy' exhibits that are largely aimed at school-aged visitors with video games, superficial explanations. Although there are quite a number of specialized preservation groups with knowledgable and enthusiastic volunters, these are often woefully underfunded and frequently have to rely on politically-driven agencies for support, making longer-term plans very difficult.

Currently we have more than 50 machine tools (lathes, mills, planers, etc) in the MoM as well as several steam and gas engines, mostly from the UK but with some US and Canadian manufacturers represented, a mix typical of an early Canadian machine shop. We also have many small tools and a fairly comprehensive collection of books and documents. These are all housed in a purpose-built display space with extensive restoration facilities.

If you have any other information that you think might be useful, let me know. We would be pleased to cover any expenses related to reproduction, scanning, postage, etc.

Cheers, Alan Bays

|

softsuvner

|

Posted - 01/12/2007 : 23:31 Posted - 01/12/2007 : 23:31

Alan

You are not the only person who worries about the new trendy "interactive" ideas in the major science museums. In the UK there are a lot of engines tucked away in preservation, but many groups lack the resources to put them in context, to show exactly what their purpose was. You certainly seem to be ahead of us.

Stanley

Nearly choked on my breakfast when I read your account of meeting Herbert at Washpit. We've all had those moments (well I 'ave) when we realise that we have just opened our mouth and put our foot in it!

I was interested to read Newton's comments on the Pollit "3 rod" engine. Thinking about it, as soon as you get a bit of wear on the Low Pressure cylinder and the air pump barrel, you are going to get a bit of side thrust on the glands of the two outside rods. Both the "3 rod" engines that I have seen have all metallic packings, which may have been a consequence of that problem.

For anybody reading this who wonders what the Pollit "3 rod" patent was about, it is easier to show than describe. Couldn't find a good shot of the Washpit crosshead, so I have used this shot of the "other" working Pollit "3 rod". You can clearly see the two outside piston rods which go around the front (High pressure) cylinder to connect the Low Pressure cylinder directly to the crosshead.

|

frankwilk

|

Posted - 15/12/2007 : 10:52 Posted - 15/12/2007 : 10:52

Any reviews of this book ?? please

Frank Wilkinson Once Navy Always Navy  |

|

|

|

|