| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/07/2008 : 16:50 Posted - 28/07/2008 : 16:50

Iwas going to make an alternative toolholder for the ball-turning attachment that would take a piece of HSS but decided it was gilding the lily. I've done exactly what I set out to doso we move on. First thing was a good tidy up and clean-up including vacuuming the carpet. Newton always laughed at me for cleaning up so much but every now and again he admitted that it didn't waste any time and made working conditions better. Then I addressed a little problem I hit a couple of days ago. A good slitting saw that wasn't running concentric. I know the mandrel on the HM is very slightly bent but the saw was really bad so a bit of turning to make an adaptor, get the rotary table down and hey presto, a nice easy little set up for making sure all the teeth are the same height.

I haven't used this saw much and found it was a long way out, when I went round it some teeth were over a sixteenth of an inch wrong. So, a quick run round and then a manual back-off for each tooth and I tried it out. It's a lot better but can still be improved. I'll have a shufti tomorrow......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/07/2008 : 16:39 Posted - 29/07/2008 : 16:39

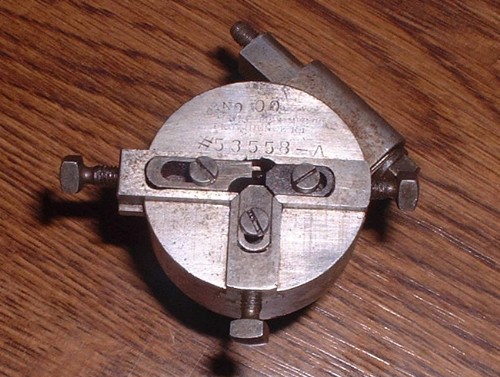

I have a bit of a puzzle. In my treasure chest are many weird and wonderful tools harvested over the years and I can put a name and a use to most of them but here's one that has me beat. It was made by Brown and Sharp, Providence, RI and has a number on it, I think the first part is the size 'No,. 00. Then 53558 - A. On the back is a parallel round spigot and there is a hole right through the middle of the tool. Anybody know what it is or what it's for?

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

frankwilk

|

Posted - 30/07/2008 : 09:20 Posted - 30/07/2008 : 09:20

Googled Brown and Sharp looks like an off set measuring device. Very good company by the look of the site.

Frank Wilkinson Once Navy Always Navy  |

TOM PHILLIPS

|

Posted - 30/07/2008 : 11:52 Posted - 30/07/2008 : 11:52

I looked at that site last night Frank,all types of measuring devices,ie vernias ,micrometers etc ,lots of different engineering gauges,,,,first thing i thought was some kind of die for threading or repairing a damaged thread,????

"Work,the curse of the drinking class"  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/07/2008 : 11:57 Posted - 30/07/2008 : 11:57

Brown and Sharpe were a wonderful firm and the name still exists. I think it's some sort of specialised small chuck. I have mailed a man who knows in the States.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 30/07/2008 : 15:57 Posted - 30/07/2008 : 15:57

Spent ages at home looking for an old B & S catalogue that I thought I had, now I've remembered that it was in Dad's collection!

Certainly a specialised piece of kit - for clockmaking perhaps?

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/07/2008 : 16:18 Posted - 30/07/2008 : 16:18

Thanks for taking the time. I have an old L S Starrett catalogue that is a gold mine. Wish I had a B&S.....

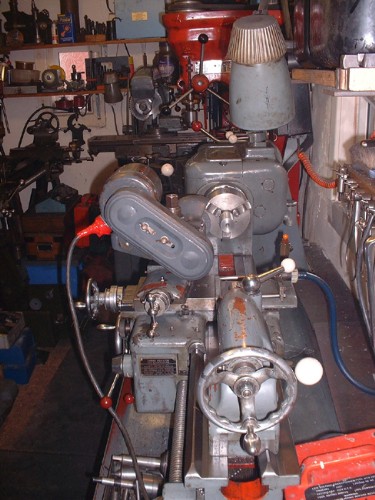

I started playing about this afternoon to improve the slitting saw. I set a little grinder up on the mill and backed off the teeth mounted on the mandrel it runs on. Big improvement. I shall do some more but use a slightly different set-up by shifting the grinder 90degrees and using a tooth stop for greater accuracy. Even so, big improvement just using rack of the eye.

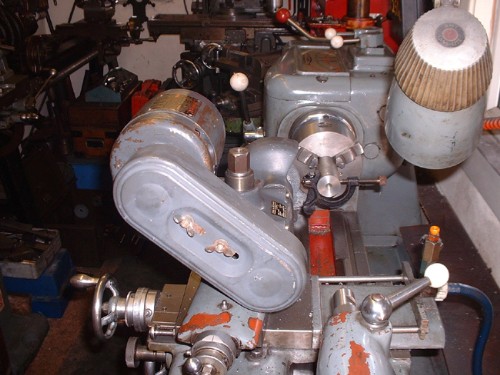

Here's a different kettle of fish. It's a Dumore toolpost grinder that dropped into my lap many years ago and I've never really looked at it. It's a bit of a goody, motor does 15,000rpm on 115V and spindle speeds vary from 45,500 to 4,500 rpm by different combinations of the 4 pulleys. The driven shaft was siezed by sticky oil so I've freed that and given it a good dose of oil, same for the motor bearings. I'll let the oil soak in for a few days and then go back to it. I have a 110volt transformer and so no probs with the voltage. A high class bit of kit for specialised jobs. Time I had a play with it!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/07/2008 : 16:59 Posted - 30/07/2008 : 16:59

I've found the Dumore website and the modern equivalent of what I have here is the 57/031 which with the accessories I have here comes to about $1800 plus tax. And I've been sitting on it for all these years! I knew it was quality but didn't really appreciate it. It needs fitting up properly so I can have a play with it.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Bodger

|

Posted - 30/07/2008 : 20:09 Posted - 30/07/2008 : 20:09

Stanley "rack a eye", i use it myself, but where does it come from?.

"You can only make as well as you can measure"

Joseph Whitworth

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 31/07/2008 : 07:51 Posted - 31/07/2008 : 07:51

Don't know Bodge but like me, it is old. It used to be accompanied by twist of the gob.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 02/08/2008 : 17:27 Posted - 02/08/2008 : 17:27

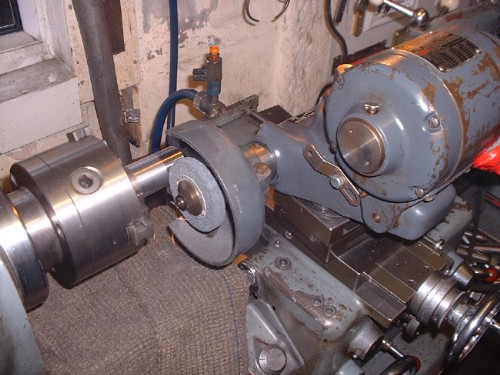

I've been busy. I had to make a retaining bolt to fit the tool post pillar, have a good strip and clean up and build the grinder back up and mount it.

Here it is almost finished. I was beginning to suspect it had seen hardly any work despite the scarring of the paint on the motor which I think has been caused during storage somewhere by parts floating round inside the box when it has been moved. The belt guard had never been fitted, I had to elongate the holes in it to get it to fit with the largest pulley mounted on the spindle to get a speedof 6,500rpm for a 3" wheel (speed range is 4,500 to 45,000 rpm with four interchangeable pulleys). The clamp on the workpiece is a tiddly little diamond wheel dresser which is part of the kit and had never been out of its box. This is used to dress the wheel dead parallel with the workpiece before use and of course comes off before any work is done. The only problem I hit was getting the pulley off the motor to fit the smallest one to gear the speed down for a 3" wheel. I got the grinding spindle nut off easily but the motor spindle was as fast as a thief. Penetrating oil, shocking it with a punch, heat, I tried every trick but no joy. Then I got my lupe out and examined the end of the thread that was showing...... You've guessed it, LH thread! No problem. Funnily enough the threads on the spindles are 1/2" UNF, 20tpi, not a thread I would have expected on an American machine.

Once all the mechanicals were set up all that is left is the electrics. I took the brushes out to inspect them and here they are, just about brand new, lots of work left in them. More evidence that the unit has seen no work. So a bit of fiddling in the sparks department to get a connection from an American powerplug to a standard 110V connector for the transformer. I think Imentioned before, the motor is 1/2HP universal type for DC and AC up to 60 cycles at 115V. The 110V supply from the transformer will run it OK.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 03/08/2008 : 17:22 Posted - 03/08/2008 : 17:22

Brushes cleaned up and inserted. Next job to make a safe and secure connection to the motor without damaging the original socket because I have sent an SOS to the States to get my mate to find me one so I can use it for authenticity. However, we can't wait for that so here's what I did.

I think it's fairly clear how I went about it. Not orthodox but secure. Once I had actually made the connections I embedded the whole lot in Plastic Padding and yes, I checked, it is a very good insulator. I checked the connections for continuity with the meter before I encapsulated it and it was OK. I don't think anyone could fault the connection on safety grounds. Tomorrow we'll see whether I have got it right!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 04/08/2008 : 06:31 Posted - 04/08/2008 : 06:31

I had mail about the grinder and one of the questions was 'What will you use it for?' A good question and of course there is no answer to it. I won't know until it is needed. A bit like any other machine, it sits there until there is a call for it and I suspect to TP grinder will sit for longer than most but that isn't really the point as far as I'm concerned. Like the 1950 lathe it was neglected and useless until it was breathed on and I get a lot of satisfaction out of bringing stuff like this back to life and learning new techniques. I have one use for it right away. I have two expanding mandrels in the cupboard under the lathe which have always sat there totally useless as the gripping surfaces aren't true and they are too long to go into the T&C grinder without making a new set-up and even then I doubt if the traverse is long enough to grind them in one pass. It will be a doddle to true them up in the lathe and on automatic traverse as well. Luxury grinding! One thing I have always shied away from is grinding in the lathe because of the dust but I suspect that with the very fine cuts which are possible with the lathe that the dust will be minimal and a strategically place cloth will shield the bed.

Theoretically I will be able to get down to less than a tenth of a thou by guess but I know I can get a tenth of a thou cut dead on by using the offset on the top slide set to 5.75 degrees and thus one thou on the register gives a tenth of that on the cut. I'm sure you all knew that trick. Apologies for teaching you to suck eggs.

So, time spent rescuing good tools is never wasted and whoever takes over the shed when I die will reap the benefit as well........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 04/08/2008 : 10:46 Posted - 04/08/2008 : 10:46

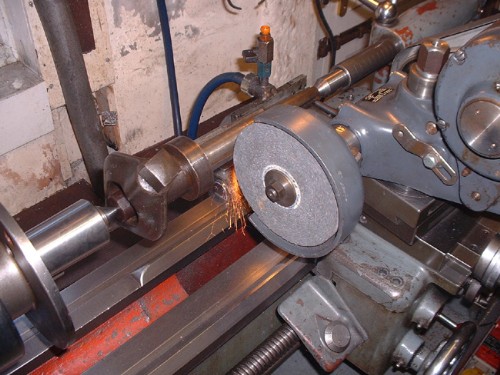

I deserve a sit down and a cup of tea! I have to admit to having a very small shake on. Last time I had such an exciting time was when Newton and I ran Ellenroad for the first time..... The tool post grinder has been tested.....

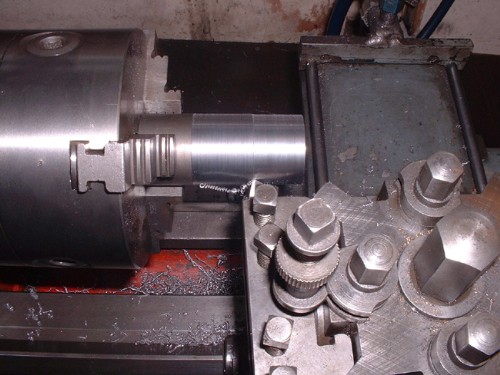

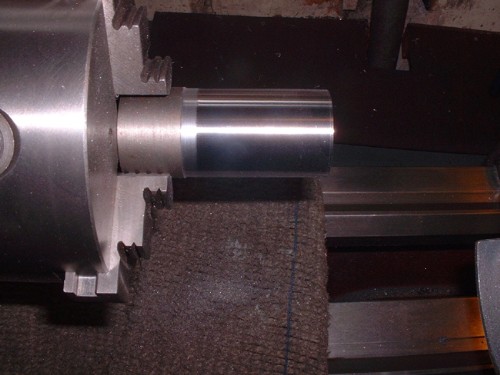

First thing to do was take a normal fine cut down the workpiece to ensure it was concentric. The best 3 jaw in the world can't be guaranteed, this one isn't bad but even so, no room for any mistakes here.

Next job was to mount the grinder on the toolpost, check all the adjustments for tightness, connect it up to the 110V transformer and then, making sure nothing was fouling, press button B. This is where I got my shake on, remember this thing hasn't run for at least thirty years! It lierally exploded into life. The motor does 10,000rpm and the spindle is geared for 6,500 for the 3" coarse wheel. I have to report that it's a savage little beast and quite frightening! However, all was well, I let it run for five minutes and nothing untoward happened. The only bearing that warmed up was the non-bearing end of the motor but this actually dropped in temperature later on as the cut progressed and it bedded in. I gave the motor the standard SG earth test, I spit on my finger and touched it. This isn't as daft as it sounds. It's 110V so not life threatening and I found out a long time ago that I am very sensitive to earth leakage. We had a top-loading washing machine and if I put my hand in it I could feel a tingle, just earth leakage due to humidity. Anyway, the motor passed the test.

Next phase was to get the wheel as near parallel as I could with the workpiece, fit the tiddly little diamond dresser and take a couple of very light passes over the face of the wheel to make sure it was dead parallel with the workpiece.

Couldn't put it off any longer. Set the lathe spindle speed to 48rpm, check that the traverse was correctly set to the finest I could get. Make a couple of trial passes by hand until I just had contact and then put a two thou cut on and put the traverse in gear. Absolutely no problems whatsoever. Hardly any spark or dust because of the light cut, I'd put a rag on the bed to catch any dust and that was probably not necessary. The cut took about 15 minutes at this slow speed and everything ran cool, in fact the motor bearing at the fan end actually cooled down while the cut was going on probably because of the very powerful little fan in the motor. I noticed when I got to the end of the cut and switched the motor off that the temperature rose slightly. Must have been the rotor giving its heat up.

Here's the result with one pass. I can't fault it. Probably the best finish I have ever achieved on a lathe. One thing that surprised me was the fact that even though the wheel is a coarse wheel, this doesn't affect the finish. I'm used to hand grinding where the finer the grit the finer the finish. Dumore say that in the larger sizes of wheel, anything over 3" they should always be coarse wheels as they have the strongest bond. Whatever..... So there you are, all is well and we have a functioning grinder with, as far as I can see, no faults whatsoever.

Seeing as how I know the grinder is perfectly set up after this cut, I shall get the expanding mandrels out and mount them between centres. Let's see if we can accomplish something practical!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 04/08/2008 : 18:10 Posted - 04/08/2008 : 18:10

A good walk with Jack, a bit of lunch, a two hour sleep and another short walk...... You've got to feel sorry for these pensioners, it's all go. Then a change of grinding wheel to the maximum size, 5", so I could get into the mandrel along its full length without altering the parallel setup. That meant a change of pulley on the motor to get the lowest spindle speed of 4,500rpm and that meant further adjustments to the fit of the belt guard. It's certainly never been used. Then away we went, same 48rpm spindle speed on the lathe but a lot faster traverse, I wasn't looking for a superfine finish just concentricity.

The blades on the mandrel were a long way out. The difference between the high spot and the low was almost .010". They were all parallel and the middle blade of the range was about .004" out. Twenty minutes later and they are all concentric.

So we now have a useful adjustable mandrel. I've never been able to weigh up how it came to be so far out. I have stripped it down several times to look at the beds and the fit of the shoulder in the collar but never came to any firm conclusion. For those of you who like old tool names it was made in Canada by the Rapid Machining Company. I love these old tool company names. It has a date on it, 1917- 1, and I have anidea that this isn't the patent date but the manufacturing date, probably January 1917. Did it come to the UK as part of the war effort in the Great War? Things like this fascinate me. Whatever its age, it is now a useful member of society again. I'll have a look at the other mandrel tomorrow.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |