| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Bodger

|

Posted - 09/08/2008 : 22:37 Posted - 09/08/2008 : 22:37

Chuck problem, a disc of metal drilled and machined at 120 deg, on the od , make small pistons to fit in each orifice, the bottom of each cylinder hole is drilled through to a central hole fitted with a grease nipple,, place at the rear of the jaws, pressurise via a grease gun, and tighten the jaws, the jaws are now located in their natural position, grind/ machine the front of the jaws, now depending on the size of the chuck, option 1, clamp an accurate ring in the front of the jaws, and if you can pass the internal grinding wheel / boring bar through the ring machine the rear of the jaws, option 2 if you cannot pass the wheel through th ring, remove the wheel, and mount the ring behind the stone on the wheel arbour, move the stone into position, clamp the ring and the grind to size, no problem

"You can only make as well as you can measure"

Joseph Whitworth

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 10/08/2008 : 06:08 Posted - 10/08/2008 : 06:08

Bodge, bloody good try if a bit complicated. There are a few problems though. First is that if you reckoned up the time it would take to make the fitting and costed it a new chuck would be cheaper. Newton and I came up with a similar solution but a lot simpler, Make a small plug out of a piece of bar, catch that deep in the jaws and tighten, skim out the empty part of the jaws with pressure on the plug, take the jaws out and scrifice the back end opf the jaws by grinding them below the treated section and you'd have a serviceable chuck. But..... the jaws would only be accurate for the diameter of the plug you used as wear on the scroll can't ge guaranteed to be uniform. Then there is the wear in the ways the jaws slide in, with pressure right at the back they would tilt slightly. We both came to the same conclusion in the end that the biggest problem of all is that scroll chucks are inherently inaccurate, the only dead accurate chuck is an independent four jaw with the workpiece centred by using a clock. Next most accurate is collets and the worst adjusted three jaw chuck can produce dead accurate work by starting with an oversize workpiece, turning it true and never taking it out of the chuck till it is finished. The bottom line as far as we were concened was that if a chuck is not accurate and you have no other, just live with it. As Newton said, there wasn't a chuck in the shop at Wellhouse Mill that was accurate to the standards we were looking for and it had never cost them any sleep. So we dropped the whole Idea and moved on. It was a nice little puzzle and educative but in the end it wasn't practical. When we'd arrived at this conclusion Newt told me that Johhny had posed the same problem to him when he was a lad and let him have a go. When he eventually failed, Johnny told him he had asked the men at Pratts the same question and they told him that in the early days of the industry Pratts had looked into the question of reconditioning scroll chucks and dropped the idea as being impossible.

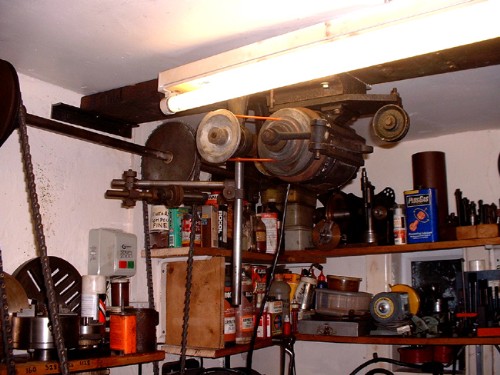

Ringo is right, the job is done but it wasn't easy. I'm very grateful to him because without him I couldn't have done it because of the weight. Anyway it's in place now and I can play about with it today getting it wired up, rotating the right way and set up to work. I need another lamp in that corner because it's blocking the light and in case anyone is wondering, being a shortarse, my head just clears the unit when I'm at the lathe! This is definitely my last territorial demand in the shed, any more would be counter-productive.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 10/08/2008 : 16:32 Posted - 10/08/2008 : 16:32

Right, here it is. The 1950 lathe now has a functioning and very versatile overhead drive. Not the one that Johnny used but I hadn't enough height or room to get his in. In truth, this drive wouldn't have done for Johnny because even though it is a half horse power motor in won't take enything heavier than a 1/4" cord drive which wouldn't have been heavy enough for the turret clock gear cutting he did on this lathe. Even so, I think he'd be pleased to see it complete for the first time in almost 30 years. As I mentioned before, the motor needed reversing but when I swapped the leads over it still ran the same way. I was muttering all sorts to myself about the man who put the sticker inside the terminal cover which said it could be reversed by reversing the mains leads and then I had a smoke and a thought. I opened up the cover and read the instructions again, but this time I really studied what it said. I had to apologise to the long dead man, whoever he was, what he had said was that the mains leads had to go to terminals 1&3 but to reverse the moor you had to swap the motor leads, not the mains leads...... As my old dad used to say, when all else fails, read the instructions! I swapped them over and when I pressed button B it rotated the right way. All that was left was the pull cord for the clutch on the unit. The motor runs light until you pull the cord to engage the drive. I found a lignum vitae carpet bowl and drilled it for the cord so it has a high class and comfortable pull on it. You can see it hung on a cup hook to keep it out of the way when not in use. As I suspected, my jead brushes against the bottom of the moyor occasionally but it's only a slight glancing blow so that's all right! A good clean up and now we box on with the next job. I'm going to use the set-up of the grinder on the H mill table to true up all my slitting saws, this time I shall use a tooth peg to make sure they are concentric.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 19/08/2008 : 07:39 Posted - 19/08/2008 : 07:39

My shed is too tidy and I'm getting the itch to make muck. I got the drawings out for the Hemingway version of the George Thomas kit I have but then realised that the last thing I want to do is make a dividing head for a Myford so if anyone wants to buy the kit, let me know. I have all the drawings and parts. A good project for someone. I bought it years ago off Neill when I was doing quite a bit of business with him.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 22/08/2008 : 11:26 Posted - 22/08/2008 : 11:26

You live and learn..... I've been having a problem with my £3000 super CH boiler and British Gas haven't solved it yet. So, as part of my investigation and diagnosis so I can give them the best information when I finally get them back to it I decided to fit a pressure valve in the CH circuit so I could pressure test it. Dead easy because there was a drain cock on it. So a good little gauge, a couple of hose clips and some flexible tube. Nowt to it. Problem was the drain cock leks when it is opened. Spotted the mistake? It took me a minute or two to realise that the fault was the fact that being a simple drain valve it had no seal on the gland...... Ah well! I went a different route and proved the circuit but during the process I had a bit of an accident. I dropped the gauge down behind the wooden casing that tidies the pipework up. Bad language and mental arse kicking. Then I got the magic wand out and fished it out.

This is one of those little tools that you often fall for and never use but this is invaluable and has saved my bacon many times. It's telescopic and has a small but extremely powerful magnet on the tip. Works like a charm!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

jgb7573

New Member

44 Posts

|

|

Posted - 12/09/2008 : 14:25 Posted - 12/09/2008 : 14:25

Having moved house last year I've been setting up the workshop in the garage, which is attached to the house. The size and position of that garage was a big factor in deciding which house to buy.

Between gardening, decorating, and the other joys of being a working parent of two sub-teenage children, I've made some progress with getting the workshop sorted. I've built a bench with vice and drilling machine on it, and last week was making some simple drawers to hold taps and dies. Having glued and screwed the drawers, I headed indoors, to find my wife had retired for the night somewhat earlier than usual. Her head was now a bare 6 inches from the bedroom wall, to the other side of which I'd screwed the bench. To be fair, her comments about the noise and vibration were not very pointed (nor even blunt ;-), but I now find the need to redesign the workshop layout almost irresitible. Deep joy!

JohnB,

Found that horn - gorn!  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 12/09/2008 : 15:52 Posted - 12/09/2008 : 15:52

Just shift the bench and make it better than you did the first time. Started thinking abit outside walls and remembered the gas fitter's story obout the DIY boiler installation where the bloke misunderstood the meaning of 'install on an outside wall'. Hed put it outside with a small roof over it.......

For any shed addicts. Reason for silence is they persuaded me to write a History of Barlick. I'm getting there......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 27/09/2008 : 10:58 Posted - 27/09/2008 : 10:58

History of Barlick finished and with Heather who is polishing it up. Choice this morning was vacuuming the carpets or into the shed......

So what's he up to now? One of those satisfying little maintenance jobs. Doc gave me his old swivel chair because it was better than mine. Only one problem with it, an annoying looseness in the connection to the base so a quick strip down and make a new washer for the attachment at the base which includes a shoulder to take the play out of where it locates. Still a bit of play in the hydraulic cylinder but possible better than it was when it was new. Now that's what I call satisfaction, doing something that couldn't be done without a shed. Can you just imagine going to an office furniture retailer and asking them if they repair swivel chairs? Lovely.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Bodger

|

Posted - 28/09/2008 : 10:04 Posted - 28/09/2008 : 10:04

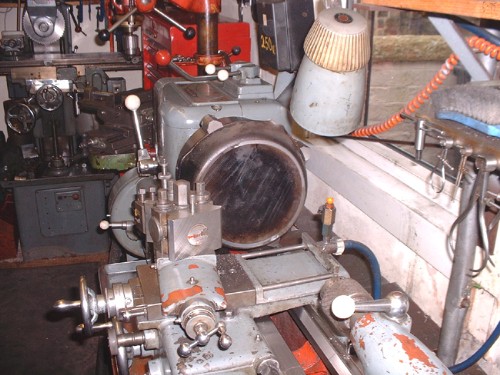

Stanley, an interesting tool holder, what is the purpose of the taper ended flat bar adjacent to the chuck ?, also what is the round bar that spans the bed ?. Tony

"You can only make as well as you can measure"

Joseph Whitworth

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/09/2008 : 17:48 Posted - 29/09/2008 : 17:48

The flat bar is the top guide that stops the parting tool dipping and digging in. I got it in a workshop clearance and have used it ever since. The bar takes all the downforce. The round bar is just one of two bolts that holds the bed guard in place on the saddle.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/03/2009 : 07:56 Posted - 01/03/2009 : 07:56

Five months since I posted anyting in the shed. I haven't been in there at all apart from splitting kindling. Been too busy writing and publishing books. However, all this sitting at the computer isn't doing me any good so I'm going to have a gentle tidy up and wipe down. Who knows, something may grab my fancy......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Gugger

|

Posted - 01/03/2009 : 14:43 Posted - 01/03/2009 : 14:43

Stanley, welcome back in the shed. The best place to let the mind wander.

Walter

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/03/2009 : 16:00 Posted - 01/03/2009 : 16:00

Hello Walter... not got in their yet, too busy writing for the BET so I can get them off my back. Back better for not sitting here too long....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 04/03/2009 : 09:05 Posted - 04/03/2009 : 09:05

You'll be glad to hear that I put on the barrier cream and me smock and went into the shed this morning where I had a good tidy and clean up. The advantages of a heated shed showed up. Despite the cost of gas, the shed has been kept at a constant 50F all winter and there is no sign of any condensation or rust, everything just tickety boo. Thoughts are stirring in the back of my mind...... We'll see if they get strong enough to get me in there in the near future. To be quite honest, I'm enjoying the rest and doing bits of things that have been neglected for too long, like vacuuming, dusting and generally tidying things up.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/03/2009 : 16:05 Posted - 30/03/2009 : 16:05

One of the dlights about having a shed is that if something crops up you can do something about it without spending money. So what's he doing with an old CI frying pan on the four-jaw? I've had this pan for years, it's one of those with ribs in the bottom for doing what you could call an indoor barbecue. I've never used it beyond the odd bit of steak and it's thoroughly impracticable because, like a barbecue, it fills the kitchen with smoke.

So I decided it was time it was either thrown out or made into a practical frying pan. I cut the handle off (it could soon be welded back on again) and started by skimming the base. It took two shallow cuts to get it dead true. Then I cut a chucking rim round the bottom so I could hold it to clean up the inside and get rid of the ribs. After I'd done that and taken it off the chuck I measured the thickness of the bottom. I didn't need to do this really because I knew the answer from the sound of it. The wily Oriental ironfounders had beaten me. There was enough meat to get a finish but it would have been paper thin so I ditched it. All right, I'd wasted my time but at least I'd had a go! It's no longer sat there reproaching me for not being used.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |