| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Another

Traycle Mine Overseer

6250 Posts

|

|

Posted - 26/01/2005 : 09:58 Posted - 26/01/2005 : 09:58

Nandy, whoooa - no-one said you were a proper Yorkshireman, unfortunately you will never be able to achieve such hallowed status. Make do with the honorary bit and get your hand in your pocket. Nolic

" I'm a self made man who worships his creator"   |

andydiamond

Hairy Horologist

424 Posts

|

|

Posted - 26/01/2005 : 12:15 Posted - 26/01/2005 : 12:15

Bugger off, I have never yet seen a proper Yorkshireman get his hand in his pocket,(apart from to pull out a rather grubby hanky)so I'm not doing it either.

Andy.

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 26/01/2005 : 18:07 Posted - 26/01/2005 : 18:07

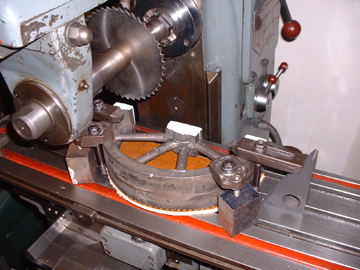

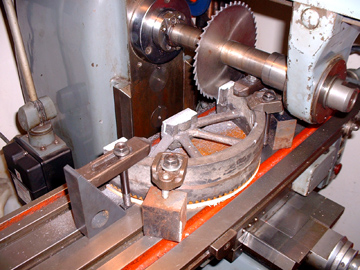

Time we raised the tone a bit. Here's a nice little setup on the horizontal mill for you to criticise...

No, I'm not going to make a mill engine but years ago I saw this pattern at a foundry and asked them to cast me two as well. I have a fancy just to make it up on a shaft with eccentrics and proper steps.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

andydiamond

Hairy Horologist

424 Posts

|

|

Posted - 26/01/2005 : 19:33 Posted - 26/01/2005 : 19:33

Very nice Stanley, where is all the swarf ? It looks like a picture out of "Model Engineer".

Still, I wish that miller was in my workshop......

Andy.

|

Ringo

Site Administrator

3793 Posts

|

|

Posted - 26/01/2005 : 22:28 Posted - 26/01/2005 : 22:28

Is the cutter on backwards?

|

Stevie

Mad Woman of Thornton

834 Posts

|

|

Posted - 27/01/2005 : 00:37 Posted - 27/01/2005 : 00:37

Is it a butchers bacon slicer? |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 27/01/2005 : 06:44 Posted - 27/01/2005 : 06:44

Andy, haven't atrted cutting, just spending a lot of time setting up. If you think about it it's a tickle job because you cant measure accurately as it is a rough casting and yet the joint between the two halves has to be perfect.

Ringo, nice try but no, the shaft runs counter-clockwise.

Stevie, it's exactly the same principle but instead of cutting bacon it cuts metal. I could set it up to slice anything......

On a wider note, I find that time spent setting up and thinking about sequence can save a lot of grief further down the track, this is just as interesting to me as doing the job.the joint has to almost invisible by the time I start turning the wheel so I spent a lot of time thinking about it.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 20/02/2005 : 18:52 Posted - 20/02/2005 : 18:52

Well, things have lain fallow for a while because I've been writing Arthur Entwistle up but I found a moment or two today between another article and walking with Jack. Here's the first cut completed. And BJ, no swarf, just castiron dust.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

bazshar

|

Posted - 20/02/2005 : 21:21 Posted - 20/02/2005 : 21:21

My father was a R.R. engineer and once told me a true story (Many moons ago so it is ok to repeat it publicly – I hope?) which was along the lines of:

A turbine blade had gone missing in the latter stages of production. Apparently, each process, of many, was logged on an accompanying job sheet. (Sorry don’t know the appropriate terminology) I cannot recall what the accumulative value of the workpiece was at each stage, but it was staggering.

When the discrepancy came to light, the logsheet quickly revealed the last stage completed and therefore only two possible scenario’s.

Security was to discover that the culprit engineer had ruined the workpiece, panicked, wrapped it up in newspaper and smuggled it home to throw in the dustbin.

As an aside as kids we used to be so impressed to see handguns in holders hanging in the gatehouses at Bankfield and Gill – now everybody’s got one!

When your work speaks for itself, don’t interrupt! |

Ringo

Site Administrator

3793 Posts

|

|

Posted - 20/02/2005 : 22:12 Posted - 20/02/2005 : 22:12

Last time they drained the canal at the back of Rolls there were plenty of componants to be found, that was many years ago, so no doubt it will be the same again.

When I worked there a large turbine shaft approx 6 feet long disappeard one day, after a few weeks of hunting management decided the only thing to do was to start machining another. This would take months to do but was the only option. After the first couple of operations were complete on the new shaft a specialist transportation box was required so the labourers were sent to find one. They somehow knew just where to look, in fact the box they comandered to use as a coffee table would be perfect, and guess what.....inside it was the original finished shaft.

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 21/02/2005 : 03:50 Posted - 21/02/2005 : 03:50

Newton Pickles son in law Philip worked at Rolls as a turner. They had a new and very expensive Italian lathe delivered and Philip was put on it with the techician who was setting it up. After all was prepared they put a blank in and set the machine on. Philip said there must have been a bug in the programme, it sent the cutter straight into the chuck and stopped the lathe dead. It had to go back to Italy and a new lathe substituted. Red faces and penalty clauses all round....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 11/08/2005 : 18:14 Posted - 11/08/2005 : 18:14

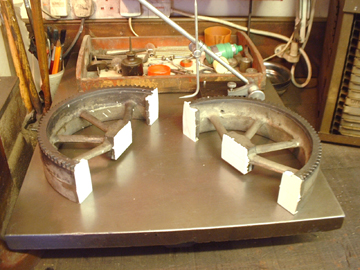

I hadn't realised that it was so long since I posted, perhaps we have lost some replies in the hacker attack. I've been busy this summer with other things and the workshop has suffered. If you remember I was playing with the castings for a flywheel like the one on Bancroft engine and last time I posted I was moaning about how hard it was to decide on a datum to measure the cuts for the mating surfaces. I did my best, milled them off and I'm pleased to report that I think I got it somewhere near. The casting must have warped a bit so it's not perfect but near enough.

As you can see the surfaces are finished, checked, ground together and ready for marking for the bolt holes. Hard to see on the pic but I've marked a notional centre line and will lay out the bolt holes from there. It doesn't matter if they are slightly asymmetrical as long as they mate. Next job is to drill the holes and make 8 fitted bolts to mate with them. Bolt it together and then I can have fun on the lathe. More later........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 11/08/2005 : 18:19 Posted - 11/08/2005 : 18:19

I've just looked back through the topic. No replies missing, it was February when I started on the casting, where does the time go?

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 14/08/2005 : 17:34 Posted - 14/08/2005 : 17:34

Another stage forward. One face on rim milled flat ready for mounting on the faceplate on the lathe and main mating surfaces milled and ready for drilling for the fitted bolts. It looks as these will be three sixteenths but I'll decide on that when I have looked to see if I have any precision bolts in stock. If not I shall make them.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Ringo

Site Administrator

3793 Posts

|

|

Posted - 15/08/2005 : 22:16 Posted - 15/08/2005 : 22:16

Glad to see that the new technology hasnt invaded your engineering and you are still working in gold old imperial measurements.

Where I work all drawings are in metric but people still say 'Can you take a couple of thou off there' so in reality people convert back to imperial without knowing about it.

|