| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

pluggy

|

Posted - 20/06/2008 : 20:08 Posted - 20/06/2008 : 20:08

Bit behind the times Stanley, the 'bloody useless' Sterling has been dusted down for the 21st Century. It has one or two saving graces that are becoming important in the age of expensive fuel. It will run on anything and can be the prime mover to generate power from waste heat that isn't high enough grade to run anything else, including steam engines. It doesn't need air or water so it will work in space. Southern California have signed up to generate 500MW of electricity from the Sun using Sterling Engines, its much more efficient than solar cells. Its also much more efficient than thermocouples used in Radioisotope Thermal Generators so they don't need to launch so much radioisotope fuel into space. The 19th century white elephant has found uses in the 21st century. You can even buy a central heating boiler that generates electricity as a sideline using the engine.

Need computer work ?

"http://www.stsr.co.uk"

Pluggy's Household Monitor  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 21/06/2008 : 05:54 Posted - 21/06/2008 : 05:54

Not the ones you can build in the workshop. I wouldn't bother building a solar cell either..... I only do things I understand and like.

Back to the real world. I think I'll have a day shelf-building and if I'm really good I'll allow myeslf to measure the RPM on the spindle in the lathe to see how clever Johnny was....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 21/06/2008 : 17:56 Posted - 21/06/2008 : 17:56

It's been a hard day...... All the goodies are back where they should be and I have won a space to stand in when running the lathe. I actually have spare space on the shelves even though nothing has been thrown away. You'll laugh at one of the reasons for this, when I was wiring the Harrison mill I put the junction box in the easiest place, on the shelf. It's been in the way ever since! 12 years later it is on the small window cill, a great improvement. That's enough for one day. The bathroom is tidy again, the hall empty, the carpets vacuumed and the engineer showered and dressed in clean clothes. Jack is exercised and fed, washing machine is working away, I think it's time for tea! I can have a proper play out on the lathe tomorrow without feeling guilty......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 21/06/2008 : 20:03 Posted - 21/06/2008 : 20:03

Well Done Stanley, it is always very satisfying to "win" a bit of space in the workshop without parting with any of those useful bits that you might need one day!

There seem to be a hard core of enthusiasts for the Sterling Engine

in Model Engineering Circles. There are books and articles galore about them. The ones that one sees at exhibitions, with bits made out of perspex, always remind me of something from a "Flash Gordon" movie of the 30's.

The original old-style Sterling Engines always seem to me like water rams - quaint old low power machines from another era.

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 22/06/2008 : 05:56 Posted - 22/06/2008 : 05:56

Malcolm, yes, you're right, very satisfying and by using my head I have actually got more room than before! However, (and this is a sign of age) I have decided that I have pushed the Tardis effect as far as is reasonable. Anything more will be ridiculous. I agree about Sterling engines. There is a hard core who spend their lives chasing greater efficiency by using exotic materials and even thinner materials to improve heat transfer. (have I got that right?) I'm not an engineer, just an old fitter and rough turner, I shall stick to CI, steel and heavy lumps of non-ferocious.

My thinking about the Mardrive unit was clarified this morning when I got mail.....

Hello Stanley,

Excuse the familiar but having enjoyed you column for so long I feel as if I know you.

Probably, it’s already been pointed out that the unit from your treasure chest of what the ill disposed are pleased to call ‘junk’ is a Pultra lathe Mardrive. A lot were three phase of course.

More info. at http://www.lathes.co.uk/pultra/index.html

Have accumulated several, it’s good to see someone else finding a new use for this beautifully made old kit. I am presently adapting an ex. cabinet version to drive my 1905 Pittler lathe.

I agree that lists of projects can stretch into several lifetimes so applying a bit of focus is no bad thing. However, that said I shall still be diving into your notes occasionally for a hint or two when building the Clarkson twin compound engine for which I recently acquired castings.

Keep writing and all the best to you.

Kindest regards, Bob Davis.

Morning Bob...... No, you're the first to enlighten me. By the way, no problem about using my forename, I'm always slightly suspicious of people who insist on formal appellations..... I've had a look at the drive on the lathes site (What an interesting source it is, I often delve into it) and I'm obliged to you for drawing my attention to it because I think you've explained something which was puzzling me. I couldn't see an obvious use for the spare three step pulley mounted in the middle of the second motion shaft. It looks as though this was intended to drive a small lathe making the whole 1/4hp unit a very compact combination drive unit for both Main and overhead drives. I'm pretty sure now that this is correct because the drive unit is mounted on the base plate via a sliding mount and of course this would be ideal for adjusting the tension on the main, fixed drive and wouldn't be needed for the o'head. This clarifies my thinking because I was giving thought to using it on the Pickles 1950 12" lathe like I did twenty years ago when I had plenty of headroom above the lathe. I'm not going to do that now for two reasons: First, it wasn't how Johnny designed his setup. I have the major parts of the original o'head drive he made for the lathe originating from the lineshaft and as his ghost is watching what I am doing over my shoulder I'd better not upset him! Second, it's a waste of a superb and hardly used combination drive. Far better to sell it to someone who can use it for it's original purpose. Now then, it's dusty, slightly rusted by age but otherwise in as new condition. The give-away is the lack of wear on the bearings, pulleys and in particular, the clutch and brake mechanism. So I have a question for you..... How much is it worth? Have you any advice as to how and where to sell it? There is another reason of course, my little workshop is now full! To the untutored eye it already looks overcrowded but as you will recognise I'm sure, not over-full but efficient, there is room to use every machine. However, even I will admit that sticking the Mardrive on the ceiling will be over the top! So any advice you can give will be appreciated. Best, S.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 22/06/2008 : 06:00 Posted - 22/06/2008 : 06:00

By the way Bob. I'm flattered by the fact you'll be looking for hints in Shed Culture but be warned, my chief attribute is the ability to produce king-sized cock-ups and I'm definitely not the best man in the world on finish! All I want them to do is to work when you put steam on them! More the Baldwin school than the Sulzer..........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

pluggy

|

Posted - 22/06/2008 : 10:12 Posted - 22/06/2008 : 10:12

You're right about modern sterlings, they use a lot of tricks to get the efficiency up. Using hrydogen or helium as a working gas and clever lightweight and thermally efficient materials. But since you made some 'conversation piece' steam engines, a small sterling you could run on the coffee table with a tea candle would wow your guests. Who cares if its only 1% efficient ?.

Lots of people have made working sterlings out of old tin cans and wire coat hangers. (look on youtube).

Need computer work ?

"http://www.stsr.co.uk"

Pluggy's Household Monitor  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 22/06/2008 : 16:39 Posted - 22/06/2008 : 16:39

Pluggy. No! I'm not interested. Make one for yourself.....

A day of small things..... Afew accessories sorted out and chuck keys found or made for all the chucks. The one on the nose at the moment is a bit of a goodie. A Taylor 3 jaw SC (I have the internal jaws as well) Regarded by many as one of the best chucks ever to come out of Birmingham. Made entirely differently than the normal scroll chuck and much stronger and less susceptible to wear because the slots for the jaws are sloping and the faces of this slot take outward shocks rather than the scroll.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

pluggy

|

Posted - 22/06/2008 : 17:28 Posted - 22/06/2008 : 17:28

I have a wife and no workshop.........

Might just run to to a kit though.

Need computer work ?

"http://www.stsr.co.uk"

Pluggy's Household Monitor  |

Bodger

|

Posted - 23/06/2008 : 09:51 Posted - 23/06/2008 : 09:51

Stanley, how many times did you have a go at getting the right no of links in the belt, brings back memories , trying to get the belts joined, the b-ggers were tight to fit when new, but not bad if they had run for a while

"You can only make as well as you can measure"

Joseph Whitworth

|

Bodger

|

Posted - 23/06/2008 : 17:11 Posted - 23/06/2008 : 17:11

Stanley, i wonder what Nelson would have made of this steam engine http://www.dself.dsl.pipex.com/MUSEUM/POWER/tower/tower.htm

"You can only make as well as you can measure"

Joseph Whitworth

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 23/06/2008 : 18:08 Posted - 23/06/2008 : 18:08

Interesting, I hadn't come across that one before. I suspect Newton would have asked how to rebore a sphere when it gets worn..... Like everyone else I had three tries before I got the headstock belt right because removing links is the only adjustment. When it's run a bit it will need another link out of it. I looked at the price of Brammer Belting on the tinternetwebthingy and goit a shock, £40 a metre! Good job I have a big treasure chest.

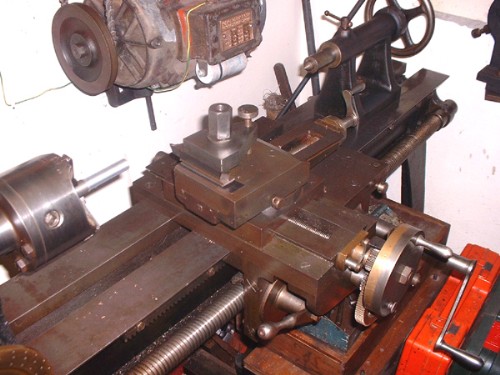

I've spent the day making a chuck key for the Taylor chuck, stripping the saddle down and cleaning and adjusting the slides. Putting the biggest train of gears on I could find to bring the auto feed down to a reasonable speed and taking the first cut on the lathe for twenty years.

Nice to see some swarf rolling off and I was reminded how well a belt driven lathe cuts, far better than any geared head lathe except for the most expansive modern lathes. The other thing that struck me was the weight of metal in the saddle, cross slide and compound slide. Good to tell it was designed and built by a turner. You can put a tenth of a thou cut on easily with the big dial on the top slide.

I found this letter this morning while I was reminding my self of the lathe's origins....

J Pickles’ letter to the Society of Ornamental Turners c.1956? Dear Mr. . . . . . . . . . . . . . To write of the difficulties in making my equipment I don’t know where to start as it goes back such a long way. I am 71 years of age, and took the English Mechanic from the age of 9, and the Model Engineer from No. 4. I served my time in a small mechanics shop in a village on top of the Pennines [Earby], with a master and his son [Henry Brown and son] who were craftsmen of the old school. They could do anything in that shop, and do it right, and they taught me to do the same. I was privileged to use the tools in my spare time if I wanted to, and paid 3d per hour for the cost of running the engine. Taking advantage of this, I and a cabinet maker friend of mine made a 4” centre S.C. lathe. He made the patterns I did the machining. In the shop we had a 12” centre lathe with a 30 ft. bed, two hand lathes, 10” centres on a wooden bed faced with iron plates 28 feet long, and a 42” foot lathe made by my master and used as a pattern lathe. We had no twist drills, and used home-made reamers, no chucks as we know them nowadays. We also had a small side planer, made by the master which was capable of planing 2’ 10”, this was the length of the bed of the lathe we made. Early in my apprenticeship I was taught pattern making, this enabled me to cut a lot of the gear which I used. At this time I owned a round-bed Drummond lathe which was used for making models, an electric clock ,and a microscope. In 1906 I saw for the first time a Holtzapfel lathe, it never left my mind, then I saw some of the lathes in South Kensington Museum, so in 1917 as my position had altered (I had been made foreman) and more tools had come into the shop, I thought I would make a lathe I could do something on. I then set about making the patterns for a 6” centre single geared lathe (treadle) with a worm wheel and tangent screw, a metal turning slide-rest. With this lathe I did an enormous amount of work, making a planing machine to plane 2’ 2”x8”x6”. The patterns were made by hand at the works, but all turning, drilling, some cutting and fitting was done at home. At this time I parted with a round-bed Drummond lathe, but after it had gone I found out it was nice to have two lathes so I started to make a plain lathe just for polishing, drilling etc. It was about this time my wife said to me “Why don’t you make something and send it to the exhibition the same as other men do?” I had at this time seen a notice in the English Mechanics referring to the Turners’ Exhibition so I finished the fast headstock and sent it to the Mansion House in 1927, and was awarded a bronze medal. This inspired me to make a “posh” lathe, so after a little bit of studying, I decided to make it into a front slide S.C. lathe on the lines of Birch of Manchester. The lathe was made by the aid of the aforementioned planing machine and the foot lathe to which had been added screw cutting gear to the slide rest. When the lathe was finished I sent it to the Model Engineers Exhibition in 1927, and was awarded their Silver Medal. The ornamental slide rest, and the Epicycloidal Cutting Frame shown in the photographs, were then made for this lathe, and afterwards forwarded to the Turners Exhibition in 1929. For these items I was awarded a money prize, and in the same year was awarded a silver medal at the Mode1 Engineers Exhibition, also a Bronze Medal at another exhibition in Bradford. With the tools I then possessed, I made a turret clock movement, cutting all the wheels, some of 12 D.P. in cast iron and gunmetal on the treadle lathe. For this I was awarded a Silver Medal in the Model Engineers Exhibition in 1931. This clock has been running in a church about 100 yards from my home [Roman Catholic Church, Gisburn Road], for 25 years, and has never been stopped for any fault of its own I then made another clock which was installed in another church [Riley Street Earby, later installed in Wellhouse Machine Shop and today on Gissing and Lonsdale’s office on Wellhouse Road] as a monument to my old master. In addition to these I have made 4 regulators [Astronomical regulator clocks]. Returning to the subject of the lathe shown in the photograph, it was in about 1922 that I saw described in the Model Engineer a lathe for ornamental turning etc., which had 3 spindles, and was a S.C. and Medallion lathe. It had been made by or belonged to William Hartley of the geometric chuck fame. I thought I would like to make a lathe on these lines, so started with the patterns for the fast headstock. This was just before the last war broke out. In the meantime I found a 6” centre Milne’s lathe in a brokers shop, it was a plain lathe, fitted with a compound slide-rest, so I bought it for the bed and legs. It was fitted up as seen in the photographs, with a new tail stock and slide-rest, and eventually with Screw Cutting Gear. I then thought I would go the whole “hog” and make it into a proper S.C. lathe, having made the screw in the meantime on the old 12” lathe referred to earlier in the letter. In the meantime the Geometric Chuck, Universal Cutting Frame, Eccentric Frame, and Drill Spindle, Heavy Milling attachment, and a Vertical Slide had been fitted. You want to know about the snags, well I don’t think I have had any, but I have had all the pleasure in the world doing this work and would like to go on with it still. I don’t seem to have done much in connection with Holtzapfel Vol. 5. The enclosed photographs show some of the parts of the lathe, also a clock made recently, and a microscope, I have just finished an 8” telescope. I will say again I don’t remember any snags, and also I have never made any drawings for any of the things I have made. Regarding what I do for a living, I am Managing Director of Henry Brown, Sons and Pickles, Ltd., Barnoldswick. We are Engineers Millwrights and Machinists. We do all kinds of work on engines and mill gearing for the Lancashire cotton mills, and also a large amount of machining for outside firms. We can turn up to 9 feet in diameter, shafts up to 28 feet long, screwcutting up to 26 feet long. We employ 30 men, and follow about 100 cotton mills, so you can appreciate that I have plenty on my plate at times. Yours . . . . . . . What a man, the Milne's lathe he refers to is the bed and legs of the 1950 lathe. We need blokes like Johnny today, surely they must be out there somewhere?

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Bodger

|

Posted - 23/06/2008 : 23:35 Posted - 23/06/2008 : 23:35

Stanley, i was 3 years into my apprenticeship when Nelson wrote that epistle, i started in a steam power, belt driven shop, doing the usual, turning, milling, grinding, shaping, planing, i ended up as machine tool fitter, the foreman fitter was Bill Lomas, his 1ft. steel rule stopped us from misbehaving, a twelt across your backside would be felt for hours, my final post before entering the "new" plastics industry was, doing service and installation, i rated myself pretty good, but reading the letter and your appraisal in the Lancs. Textile article humbles me, as you say ,are there any truly hands on , head thinking craftsmen of is ilk out there in this modern world, i'm afraid only a few, the loss of the UKs machine tool industry saw to that, now no one wants a job where you get your hands dirty, but down the line, there was someone who made the moulds and machines that made your computer bits and pieces, probably in China

"You can only make as well as you can measure"

Joseph Whitworth

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 24/06/2008 : 07:09 Posted - 24/06/2008 : 07:09

It was Johnny Pickles who wrote the letter Bodge, shortly before he died and Newton (Not Nelson) was his son. Some of the jobs they did were amazing. During WW2 they were consulted about machining some big turntables, not sure what they were for. The country was short of big lathes. So Johnny took the order if he could be allowed a large quantity of metal which was rationed. He built a break lathe into the fabric of the shop, it was 4' 6" centre height and could take about 12ft between centres. They used that lathe from 1940 until it was eventually scrapped a few years ago by Gissing and Lonsdale.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 24/06/2008 : 08:26 Posted - 24/06/2008 : 08:26

The more I dig into Johnny and his works the more impressed I get. If you go searching for Milnes and Birch lathes and study the designs and pictures you begin to realise that Johnny was very well read and informed about lathe types. The Silver Medal lathe of 1927 is a good example. By the way, Newton told me that if Johnny hadn't been a professional engineer the lathe would have got the gold medal, they automatically dropped professionals down one place. It's almost a direct copy of the Birch, I know this because I once owned one of the nine Birch OT lathes known to exist and sold it to a bloke near Hebden Bridge. However, there are subtle differences where Johnny has used his own ideas. The 1950 lathe is even more a Pickles lathe. He chose the Milnes bed because he knew it was cast with quality metal and it is a classic English flat bed with outside 'V' guides, massively built with no gap and therefore maximum strength and resistance to torsion. The headstock he built has Milne features but nods towards Birch as well. Like many lathes of the period it has a solid mandrel for maximum strength. On the 1927 lathe Johnny used hardened steel on CI bearings, the front one being tapered for adjustment. When he built the 1950 lathe he used the solid mandrel and taper adjustable bearing but running in bronze bearings. Milnes favoured mounting the tangential dividing gear on the tail bearing side of the drive but Johnny put his on the chuck side. He also incorporated a thrust bearing between the tail bearing and the adjusting bars. Overlaying the design is the detail and the lovely tool finish. The whole thing shouts utility and excellence. I know I'm going over the top but it's as near perfection as you could get, no wonder it won a 'money prize'!

The saddle is as heavy as it could be made without cramping the capacity. The Harrison is a genuine 11" swing as compared to the 12" of the 1950 lathe but when you look at the weight of construction in the saddle there is twice as much metal in Jonny's. Just one example, the tee bolts that clamp the compound slide onto the cross slide are 5/16" on the Harrison and 1/2" BSF on Johnny's. The register dial on the Harrison cross slide feed screw is 2 1/2" diam., on Johnny's it is 5". Only a small thing but it means the thou divisions are big enough to be easily split by the eye. That's a turner's touch.

I'd better stop, I could go on all day..... One final thing, I've never seen a geared SC lathe with as many change wheels. I think there are about 50! I don't think there would be any problem cutting any thread you wanted on this lathe!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

|

|

|

|