| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 11/12/2007 : 17:14 Posted - 11/12/2007 : 17:14

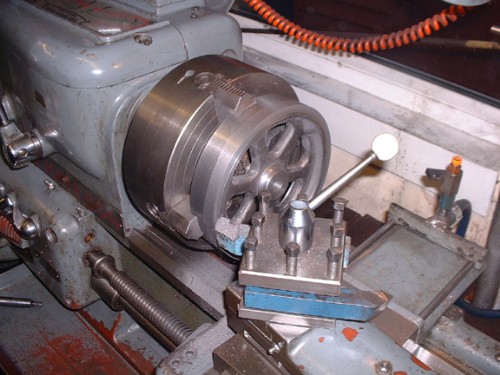

Getting serious about the truth of the re-chucked flywheel before I finished it off. If you notice I've taken the top slide off and given it a good clean and nipped the adjusting screws on the 'V' packing to tighten it up a bit. I did the same on the cross slide as well. They slacken slightly of course over the months and it isn't until you start looking at half thou cuts that you realise it would be a good idea to do a bit of maintenance.

Finishing the side of the flywheel after trueing the face. It was about 3 thou out of true. Part of this could have been chucking but I doubt it, always remember that as you cut metal off castings they alter shape because of the internal stresses coming out. This is true even with twenty year old castings like these. I first learned this when I was reconditioning valves for John Ingoe, there was a limit to how accurate you could get them because even a 50 year old casting would breathe as you turned it. I finished the day off by doing the facing cuts on one side of the last flywheel and poking a 3/16 drill through the centre. I'll turn it in the chuck tomorrow and finish it off apart from the final sizing of the bore. That's a hand job with the reamer and some gentle keyway filing and fitting.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 11/12/2007 : 18:37 Posted - 11/12/2007 : 18:37

Still playing with my new digi cam, don't think it is set up right yet. One of my test pictures was taken when the Triumph alternator business was in full fling:

Having seen views of the purposeful workshops of Stanley and our Swiss mill-engine builder Walter, I thought this shot might serve to show that non-professional engineers use space in a subtly different way!

Of course I know (more or less) where everything is, and I do clean the machines and put all the tools away between jobs. My shed sessions are snatched at odd hours so, while a "job" is running, things tend to get left so they are to hand (or at times underfoot!).

I obliterated the bike reg. in case the elfin safety want to trace me to discuss the electrics of my shed! All the juice from the house goes through a big Cut-Off switch, never fear!

I did ask a more organised friend if he could think of anything to improve the ergonomics of my workshop. After some thought the best he could come up with was "you could try and lose a bit of weight".

malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 12/12/2007 : 06:50 Posted - 12/12/2007 : 06:50

Nowt wrong with that Malcolm.... All the essentials, a pot of tea, radio, lathe and something to be getting on with. Workshops are very personal spaces and don't forget that I have had a lot of time to refine mine and three moves which concentrates the mind wonderfully. I've spent thirty years collecting the machinery as well and was very lucky at the time I was doing it. Bolton Tech had decided to go over to CAD machines so I got the H Mill and the Harrison lathe for about £2,000 delivered, a bargain if ever there was one. The Harrison is 11" swing and can cope with just about everything I do. I miss the big lathe I used to have but no room for it. I did consider putting it in the back yard 12 years ago but then ditched the idea..... As for electrics, there again I was lucky as the house was rewired when I came in. The workshop has a 60amp supply through its own dist board and includes a 25amp fused connection for the welder. Anyone who has tried welding on a three pin plug knows the problem. The sparks raised his eyebrows when I marked out 14 plug sockets....... you can never have too many!

As for size, I like small working spaces, more ergonomic. You soon get used to keeping your elbows in as you move past the hand wheels! The biggest bonus of corse is having it in the house with C heating. Newton always envied me my workshop, he was in huts all his life. Mind you, he liked it and loved the carpet.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Gugger

|

Posted - 12/12/2007 : 09:54 Posted - 12/12/2007 : 09:54

Malcome,

A purposeful workshop? What you can not see in the pictures is the washing machine and the washing line; I am only a tenant in my wife’s territory. The space I can use is 8’3” x 13’2”.

My problem is also that I am too lazy to search for things. So for me the easy way out of that dilemma is to keep the place tidy. Professional or non-professional engineer is in that case insignificant.

Walter

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 12/12/2007 : 15:26 Posted - 12/12/2007 : 15:26

I have the same problem as Walter..... I have so much stuff that if I don't keep it tidy I can't find anything. Mind you it's amazing what you can fet in a small space. I've never measured my shed, hang on a minute........ 6ft 6" X 14ft. So I have 91 square feet and Walter has 109 square feet so his is bigger than mine!

Here is today in the shed:

First pic is something that's so obvious that it never gets mentioned but it may be helpful to someone. Every time you put the vice back on the miller bed pop your favourite square in, or if 90 degrees round, a straight edge and just sight it up with the edge of the bed. That way you have a perfect right angle cut if you want one. I was just milling keys for the flywheels but it's automatic with me now to square the vice up. That way it's always ready if you need it.

The flywheels are finished and painted and partially fitted. I'm not satisfied with the keys and so I will refit them when the paint has dried. Enough for today...... They took another armful of blood out of me this morning...... I shall rest.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 13/12/2007 : 17:40 Posted - 13/12/2007 : 17:40

The flywheels have been sat on the radiator in the hall baking the paint.

Meanwhile...... I made eight oil cups for the flyshaft bearings. I might make the eight trunk slide lubricators tomorrow and leave the flywheel fitting a bit longer. Getting close.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 13/12/2007 : 18:34 Posted - 13/12/2007 : 18:34

Excellent tip on squaring the Machine Vice Stanley, another one I shall remember.

The single malt looks down a bit though, hope you've got some new supplies in for Christmas (treated myself today, I shall be communing with Mr Jameson over Christmas!)

Malcolm

|

Mercury

Regular Member

233 Posts

|

|

Posted - 13/12/2007 : 19:12 Posted - 13/12/2007 : 19:12

Malcolm, I've noticed recently that Jameson's has a slightly different taste - I had some in two different pubs, both were similar. I'd be interested to know what yours tastes like!

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 14/12/2007 : 06:50 Posted - 14/12/2007 : 06:50

There's no such thing as bad whisky. I have a Highland Spring and Lagavulin in reserve and Sue from BET will be delivering another bottle this week. Oh, and of course the McLeods 'As we get it', 106proof fishing boat whisky.

Malcolm, glad the pic was helpful. You can go to incredible lengths of course to get the vice square but rack of the eye with a big square is near enough for anything I do. I looked at the big engine this morning and it's amazing what a difference the four oil cups make to the looks of it. By the way, no lids on the cups because no matter what you do, condensate and muck gets everywhere when these little engines are running. The main thing is to be able to get the spout of the oilcan in while it is running. These are working engines intended to get a bit of hammer!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 14/12/2007 : 18:34 Posted - 14/12/2007 : 18:34

Mercury

Don't usually take my Jameson medicine in pubs over here, so can't say I have noticed a change. Mind you, there is the "Guinness" effect as in, "it always tastes better in Ireland". I've always put this down to the fact that Irish spirit measures are bigger than ours! (but enjoy it just the same).

Stanley

For a lazier man than yourself...the little grease cups with sprung lids are still about. They turn up at Autojumbles from time to time. I keep an eye out because nickel-plated ones were fitted to the front forks on early bikes. Invariably, the owners replaced them with grease nipples in the 1920's.

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 15/12/2007 : 08:07 Posted - 15/12/2007 : 08:07

Malcolm, I have a bunch of them in the treasure chest and would have used them but they are too big. Just had a look. Adams and Company, Coventry is the maker. Size is 1" diameter and almost two inches overall. A bit big for the bike I suspect! Just right for an old lathe headstock bearing.......

Did nothing yesterday except to make a threaded fixture in the Harrison to hold the slide lubricators for finishing. I'll makr the actual lubricators on Johnny's lathe in the front room. Luxurious surroundings for turning on a winter's day......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 15/12/2007 : 17:53 Posted - 15/12/2007 : 17:53

A day of little shiny bits. The lubricators for the trunk slides.

Every little helps, they get to look more like engines every day.

Now then, a question, any advice on how I get these two little engines out to Oz keeping them dry, safe and clean. All advice gladly accepted.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 15/12/2007 : 21:04 Posted - 15/12/2007 : 21:04

Stanley

A few tips:

A chap who exports bike parts all over the world, tells me that Parcelforce is as good, sometimes better, than the more expensive couriers.

Dont imagine that labels like "Fragile" or "This Way Up" have any meaning beyond the first reload. Assume that your stuff will be dropped, turned upside down, and travel along conveyors and be slid down things like helter skelters amongst a load of other parcels of varying weights (because it will, believe me).

I've seen a lot of freight/postal damage in my time. Customised wood or heavy plastic boxes can work, but tend to take damage badly if hit by the corner of another heavy package.

Very important to make sure that the engine is rigid within the container. Loose paper, cardboard etc can work, but an inner package of bubblewarp taped around the engine gives it a strong base. Inner packing needs to be something that won't compress too soon and allow the engine to move about..

The Chinese are, in my opinion, the experts on successful low-tech packing. They use cardboard boxes, with cardboard inner-packing, but lots of it, many, many, layers. They secure the outsides of the box with lots and lots of that cheap parcel tape (we use brown, theirs is yellow). You can't have too much tape on the outside (or too many labels).

Malcolm

|

softsuvner

|

Posted - 15/12/2007 : 21:09 Posted - 15/12/2007 : 21:09

Final thought

Don't even think about polystyrene sheet or those chips that get all over my clothes and in my hair when we are working on Freight! With a heavy object like an engine, they compress and allow movement too easily.

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 16/12/2007 : 06:18 Posted - 16/12/2007 : 06:18

You're mind works the same as mine. I'm thinking seriously about encapsulating in strong plastic, fastened on a baseboard, put in a wooden crate and steadied by injecting that foam they use for sealing cavities in the building industry. It's good stuff as long as it doesn't melt plastic. I need to think about customs inspection as well.

My mind is on eight small drain cocks......... Newton once told me that he made the plugs and handles in one piece out of bronze welding rod because when you'd made them you could just bend the handle to the shape required. Bit of experimenting needed I think.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |