| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

29/07/2011

:

06:27 Posted -

29/07/2011

:

06:27

|

New start as old topic was getting too big. Here's the LINK for the original topic.

Sheds are centres of honest endeavour and sanity, rare things these days. Please join in and tell us what you are doing in your shed. All are welcome!

[By the way, if I occasionally seem to be stating the bleeding obvious, it's because I'm aware of the fact that not everybody has the same experience so please forgive me.]

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 16/12/2011 : 06:25 Posted - 16/12/2011 : 06:25

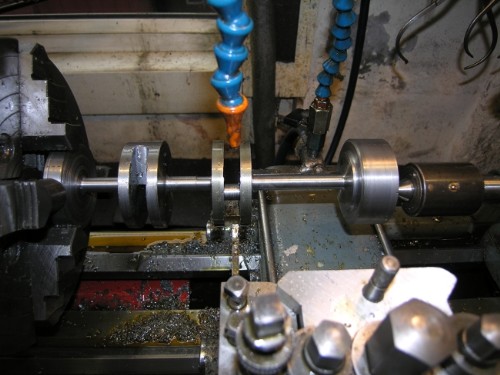

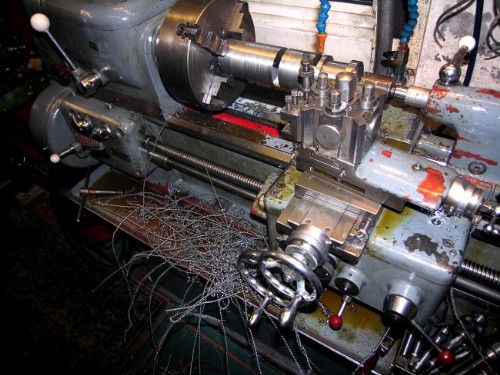

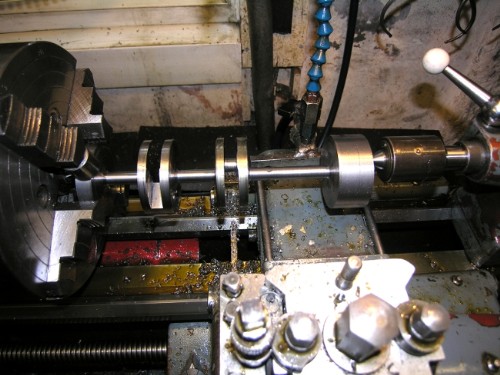

Back on track and ready to start serious, very careful, cutting. 75rpm, started with 5thou cut until settled down and then on to 10thou advance each time. Bags of oil!

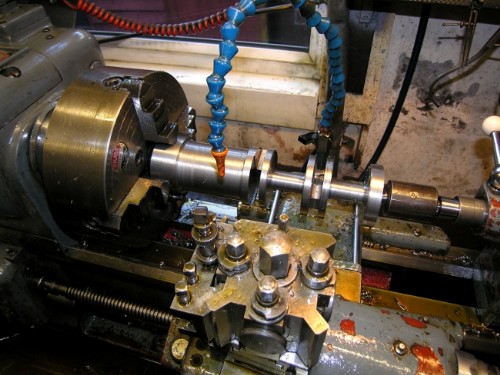

Here you are Brad! This is what you've been waiting for. The first jounal cut to finish at 1/2" diameter. Next for shaving....

Set up for next one. Tool touched up and first few cuts done. Stick to the programme and quietly away, we have it cracked now. First job this morning will be to drain the oils sump and reurn to the header tank then I can have an uninterrupted morning.

Happier now I am sorted. Programme now is to finish both crankshafts before any playing out fitting them. That will be a pleasure after all this high stress cutting.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Bradders

|

Posted - 16/12/2011 : 11:04 Posted - 16/12/2011 : 11:04

Thanks Stanley ....Exciting stuff....and I understand how it's done now !!....When you mentioned "cut to finish at 1/2" diameter" , it made me realise that the components you are making are not as large as they seem in the photos ......In fact they seem to assumed larger proportions as the project has progressed !

How long does it take to cut a journal at 75 RPM ?

BRADDERS BLUESINGER  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 17/12/2011 : 05:53 Posted - 17/12/2011 : 05:53

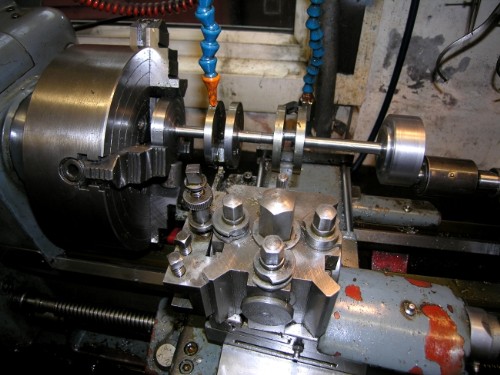

About an hour Brad but very light cuts. If anyone is doing a shaft the important part is kepping the shoulders cleaned out. If you don't you gradually develop a vee shape and have to cut the shoulders later. I clean out as I am going on, that's the difficult bit. Friday is always a short session due to shopping etc but here's close of play yesterday.

The two journals are finished and for the moment this shaft can lie fallow while I do the same process on the second billet. I'm going this way because the next operations on this shaft will be using the three-jaw SC chuck so I might as well do the other while the lathe is set up for it.

So, a couple of days of muck-shifting!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 18/12/2011 : 06:11 Posted - 18/12/2011 : 06:11

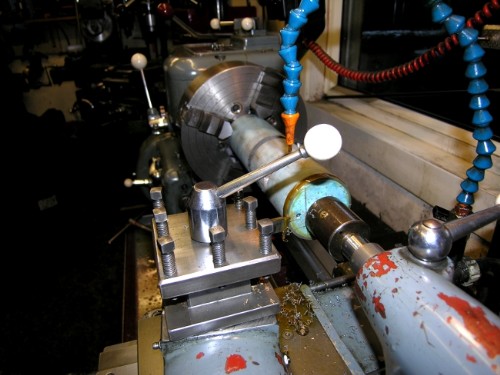

Number two billet set up and first facing cut across the end with a parting tool.

An hour later and the billet is faced at both ends, same diameter and true the whole length and webs of cranks marked with the corner of the parting tool. Ready for serious muck shifting!

Close of play at 11:00. I've started looking for the 1/2" shaft embedded in the HP end of the Billet. A good clean up of swarf, brush the carpet and we are ready for tomorrow. I shall drain the oil sump now ready for a start after the early morning walk.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 18/12/2011 : 07:41 Posted - 18/12/2011 : 07:41

Oil drained, swarf bits shifted and a quick vacuum. I'm ready to get back into muck-shifting as soon as I get back from our morning walk!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 19/12/2011 : 04:41 Posted - 19/12/2011 : 04:41

Close of play yesterday. A good morning's muck shifting with no excitement , just how we like it.... A good clean up and we are ready for more of the same this morning.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 20/12/2011 : 05:59 Posted - 20/12/2011 : 05:59

Close of play yesterday. All shaft sections taken down to a uniform level. Ready for sharpening the cutter. extending it so I can cut down to 1/2" finish, best to do the heavy cutting with a short overhang.

Swarf bin full, so rang Terry and arranged for me to dump in his scrap bin. I've rung Doc and he's going to call in today to give me a lift down to Gissing's yard. All going well.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 21/12/2011 : 05:42 Posted - 21/12/2011 : 05:42

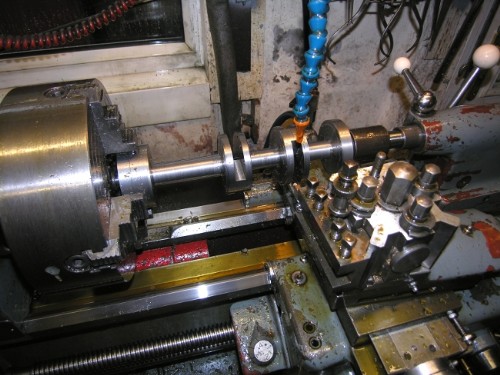

An hour into yesterday morning and I'm cutting the last section of the main shaft to finished size.

Looking healthy. Ready for crank journal cutting, just one or two hosehold tasks to do....

I work best when things are tidy so last job yesterday was to drain cutting oil and return to header tank, clean up the main of the swarf and bin it. You can see the swarf bin in the background. Doc called in after my walk and we took the bin down to Gissing and Lonsdale's and chucked it in the scrap skip. We were accosted for fly-tipping but then they realised who it was so we were OK!

All ready now for setting up to cut the two remaining journals. At that point the 4 jaw can come off the lathe and we'll finish off using the 3 jaw SC. We're getting there!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Bradders

|

Posted - 21/12/2011 : 23:40 Posted - 21/12/2011 : 23:40

Stanley ....Maybe I've missed something by not reading back to the start of this thread properly , but what are you going to do with these engines , when they are finished ?...

BRADDERS BLUESINGER  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 22/12/2011 : 05:30 Posted - 22/12/2011 : 05:30

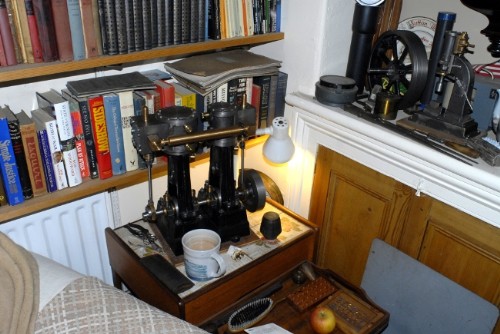

Just sit and look at them. Might sell the big compound in the front room to make room. It would drive a 15ft launch easily. I think when I've finished these two I shall breathe on the big one and then get Doc to sell it on Ebay for me. Question is, what is a big compound worth? The castings alone would cost about £1300 today......

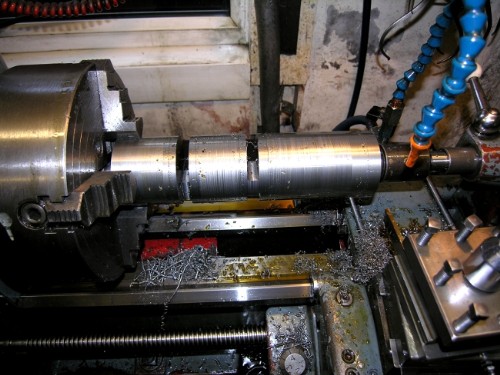

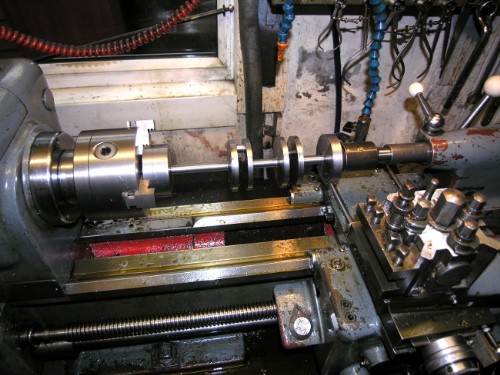

Number 2 shaft set up for journal cutting and we are working steadily and quietly.

An hour later one jounal is finished. 45 minutes later the other was done and the shaft taken out of the lathe. Clean up, 4 jaw off and 3 jaw SC back on.

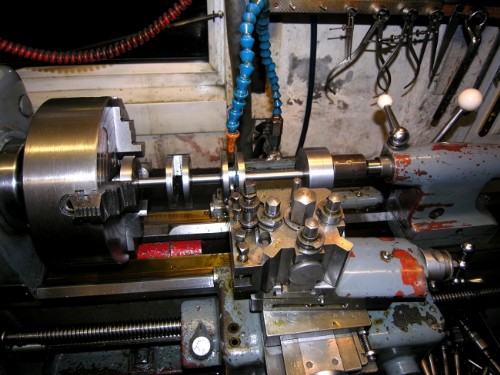

Close of play. Shaft back in the lathe centred for finishing. Nice to have the journals out of the way, always high stress cutting. The trap now is to get too confident and make a mistake in the finishing so some careful measuring this morning before I do anything and then finish each shaft.

I shall polish the journals with emery strip while they are solid in the lathe, break all the edges and finish up with a shaft with a small flange on the LP end for connection to the propellor shaft. Bahrett has a flywheel but this isn't needed with a compound and I think he built his to power a workshop. That's right, in 1920 you needed a prime mover in most workshops, no mains electricity. I think a keyway on the front end just in case anyone needs it. I shall leave the cranks as disc cranks. In commercial practice many makers did this especially if they were not having forged crankshafts made.

Nice to finish the difficult turning, it's a big step forward. Mind you, I had got into the swing of it and the last two were quick and uneventful. So, some straightforward finish turning this morning!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 22/12/2011 : 05:41 Posted - 22/12/2011 : 05:41

The big compound I made out of two modified Stuart 5A engines. Newton got the bigger cylinder castings made after I said the engine looked daft with the smaller cylinder on it. He got a special bed cast and made the same engine. I couldn't afford a new bed so I modified the box beds and put a block of steel in to join them up. It's a big lump and Doc and I ran it off his big compressor, a frightening beast at full chat!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 22/12/2011 : 07:56 Posted - 22/12/2011 : 07:56

I got diverted.... Doc and I were talking about the videos of the 5As when we ran them. The files have disappeared from the OG database but I remembered that Pluggy had posted them on Youtube for us so I went looking in the old Shed Topic. Here's what I found:

Single Stuart 5A LINK

Big compound LINK

If these don't work the title is stanleys engine I think.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 22/12/2011 : 08:02 Posted - 22/12/2011 : 08:02

Didn'r work so try this for the single: LINK

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 22/12/2011 : 08:07 Posted - 22/12/2011 : 08:07

That one works, heres the LINK for the compound running.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Bradders

|

Posted - 22/12/2011 : 22:49 Posted - 22/12/2011 : 22:49

Both Brilliant .....! Doc's use of the "hand throttle" most impressive .!

Now all you have to do, is get the shaftings in, and the whole street could have steam powered stair lifts .......

(I'll get me coat.... )

BRADDERS BLUESINGER  |