| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 31/07/2007 : 17:53 Posted - 31/07/2007 : 17:53

I had an easy day today.... didn't go near the shed until after I had taken Jack up to Letcliffe at dinnertime. I've made all the pedestal caps the right size and shape. Doesn't look much for an afternoon's work but it's a good illustration of how much work there is in the smallest bits. There are 96 finishing cuts in the eight caps not counting first passes. Of course I cheated.... i finished up doing four at once when I passed the magic rounding cutter down them but a lot of the cuts were individual. 4 hours milling in all. Now to make the bearings....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Steve48

New Member

19 Posts

|

|

Posted - 01/08/2007 : 11:11 Posted - 01/08/2007 : 11:11

Hi Folks,

Been absent, I lost my dog after a growing battle with his mental state, so this last week hasnt been an easy one.

Ian it looks like you need some help there, so please take a look on my website, I just knocked one up for you and put some photos there. I hope this helps.

http://www.workshopman.co.uk/uphill_and_son/pages/engineering/metalwork/spitfire.htm

Steve

|

panbiker

|

Posted - 01/08/2007 : 13:03 Posted - 01/08/2007 : 13:03

Sorry to hear about your dog Steve. We have cats and it's never easy when you lose one.

Regarding the Spit, easy when you know how, each to their own trade, (mine was originally electronics field and bench service engineer but been doing computers and networking for the last 20 years), I don't think I used enough welly on my first effort.

Why did I think it was Malcolm who got me started on this? Anyway, no matter as I said earlier in the thread I have about 10 quids worth of proper money to play about with so I'll get it right eventually. I quite like my mini, mini version, I might reduce it even further to give me more in the fuselage, I would then have more to play with for the tail. My problem with the first fold was that I had'nt bashed it thin enough, that's clear now. I spent 8d getting my effort right. I think I need a bigger hammer! I can see how you keep the date in place now, I'll have a go on MkII.

This simple little project just shows how good the early Bronze Age metalworkers must have been, some of the stuff I hope to turn up with my metal locator. Later Celtic jewelry is fantasticaly intricate and shows how advanced they really were with the forge and hammer and what we would probably regard as really basic tools. Thanks for the tips, I'll get one right eventually.

Ian  |

panbiker

|

Posted - 01/08/2007 : 13:31 Posted - 01/08/2007 : 13:31

Forgot to mention, I like your bike as well Steve, I ride a 1100 Pan for touring and fun, my first bike was a 1958 250 Enfield Crusader, now that thing could do damage when it kicked back! Built like a tank though. I once fell off it at 60mph on a newly surfaced proper chipping road, it hurt, lots, my mum told me I had to get rid of it "before you kill yourself", I did'nt take any notice (as is you right at 16) and I'm still here. Funny, I still feel like a kid when I get on the bike, but I don't ride like I used to when I was younger, with age comes wisdom.

Ian  |

Steve48

New Member

19 Posts

|

|

Posted - 01/08/2007 : 14:53 Posted - 01/08/2007 : 14:53

Hi,

I fell off a lot of bikes back in the sixties, survived all of them although I often wonder how. The Panther is now ready (ha ha) for an MOT, but I blew my pension on some more old iron, so next month gets the insurance going again.

A couple of things I didnt mention in my write up, best not to use a vice with serrated jaws, you can see why. The other that the tail wings are set higher than the front, so once again these can be spread with it upside down and the use of a punch.

To leave the date on it takes quite a bit of patience, as you obviously cant hit that part more than once, but it does work out, because if you think about it the fuselage is highly tapered from front to back anyway. A square punch or any old lump filed up gives you the means of knocking things where they need to be.

Have fun, Steve

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/08/2007 : 17:58 Posted - 01/08/2007 : 17:58

I'm getting intrigued with this Spitfire.......

First thing to do today was to get a flat face for the joint in the two halves of the bearings and a flat register on one end so I could stick them together somewhere near straight. I had a cutter that needed sharpening and after three goes I got the angle right. Nice chips....

A bit later and we have two faces on each half. If you're expecting pics of me soldering them together think again! I am probably the worst man at soldering in the world..... However, here is what I ended up with...

Not pretty but stuck together. Into the three jaw, get one end straight, reverse and do the other end.

I just shoved an 11/16 drill through the first four, they are going onto the small engines and will be plenty good enough. The other four are for the compound and I shall bore these properly because I have to get four bearings lined up. The metal in these bearings is the same as BR used to use for their bronze bearings. As I found out to my cost with Harry's death, bronze bearing technology is a mystery to many 'modern engineers'. These will be OK.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/08/2007 : 18:01 Posted - 01/08/2007 : 18:01

I forgat to say, I shall cut the gutter in the middle for the pedestal cap when they are all bored, a job for Johnny's 1927 lathe I think because the chuck is small enough to grab the assemblies by one flange so all the gutter can be cut at one go.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

moh

|

Posted - 01/08/2007 : 20:26 Posted - 01/08/2007 : 20:26

How many 'Stanley's engines are there?

Say only a little but say it well  |

softsuvner

|

Posted - 02/08/2007 : 06:42 Posted - 02/08/2007 : 06:42

Glad to see that I'm no longer getting the blame for Ian's Spitfire caper! When I was a kid I was taught that messing with the coins was called "defacing the coinage" and you could be sent to the Tower for it.

Mind you I was tempted by relative's tales of bending pennies by putting them in the grooves of the tram track and waiting for a car to come along. Alas, before I was old enough, London Transport removed the temptation (and the trams)!

Steve and Ian, I can tell you from bitter recent experience, that you are never too old to get caught out on a bike (by some fool in a car). If I ever doubted the wisdom of a good modern crash helmet, I don't doubt it now. Some things don't change - nearly 3 months on, the insurance company still haven't agreed a price. At least I walked away from it, and the Norton will be repaired somehow, does dent your confidence a bit though. Hasn't stopped me though, early on this week I managed to get the big Matchless through an MOT at my local scooter shop (the only 2 wheel MOT station in town) I always feel like some kind of dinosaur when I turn up there!

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 02/08/2007 : 06:59 Posted - 02/08/2007 : 06:59

Moh, there are four engines on the go at the moment. I need three to give my daughters one each. I already have one finished that I did 20 years ago. So out of the four I am doing, two are for the kids and I shall stick the other two together with a bigger cylinder on one and make them into a single compound engine twice as big as the others.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

panbiker

|

Posted - 02/08/2007 : 10:20 Posted - 02/08/2007 : 10:20

Malcolm, don't know what it was that made me think that it was you that seeded the Spit thing anyway glad you OK from your spill. That's always been the main problem with bikes, making sure your'e seen. I dropped mine, fully loaded for 2weeks touring at a temporay junction in the middle of road works on the outskirts of Orlean in France. That was a driver who could'nt make her mind up at the junction, set of and then rammed full on as I was following her out of the junction, only doing about 10mph but it does dent your pride a bit. Sally hopped of the back as it went down. I ended up on my side in the middle of the road still astride the bike. A bit of a lump to pick up when it's on it's side as well.

Back to shed things, hedging my bets with my first go at the Spitfire, I will continue with the one I've done but do think it's a bit small. I heated up a few more pennies last night and I've brought them into school with me, going to take them down into the DT dept and give them a bashing with a big hammer on the anvil. Steves instructions that he put up for me on his site has shown me the errors of my ways. A picture's worth a thousand words.

With regard to defacing coinage Steve, youre right it is essentially illegal to tamper or attempt to alter the coinage of the realm. As I am playing with coins that are no longer legal tender I don't think I'll end up in the tower. Historically in olden times you could be hung or worse for tampering with coins, the practice was widespread though, it must have been really tempting to clip coins when they were made out of solid gold and silver. Merchants would accept bits of coins as payments for goods and services, it was quite common to chop a coin in half if that was the amount of cash you needed, if it was a smaller amount you just clipped off a portion of the coin as payment. You could always melt down the bits and make them into something else.

Anyway, onward and upward with the Spit bashing.

Ian  |

pluggy

|

Posted - 02/08/2007 : 13:16 Posted - 02/08/2007 : 13:16

I learned something today  reading panbikers post and did a little experiment with a fridge magnet. Old 1p pieces aren't magnetic, new ones are...... reading panbikers post and did a little experiment with a fridge magnet. Old 1p pieces aren't magnetic, new ones are......

I'm interested in the machining of the crankshafts from the big lumps of steel bar when it comes around.

Need computer work ?

"http://www.stsr.co.uk"

Pluggy's Household Monitor  |

panbiker

|

Posted - 02/08/2007 : 15:33 Posted - 02/08/2007 : 15:33

Pluggy, have you read my post at the top of this page, potted history of metal alloys used for english coinage, (well at least since they started making them from base metals instead of pure silver and gold)? The modern "bronze" coins are copper coated steel. See also the post in the spitfire thread re defacing coins of the realm.

Ian  |

panbiker

|

Posted - 02/08/2007 : 15:34 Posted - 02/08/2007 : 15:34

Whoops, sorry it's just prior to your post in THIS thread, must be losing my marbles!

Ian  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 02/08/2007 : 18:10 Posted - 02/08/2007 : 18:10

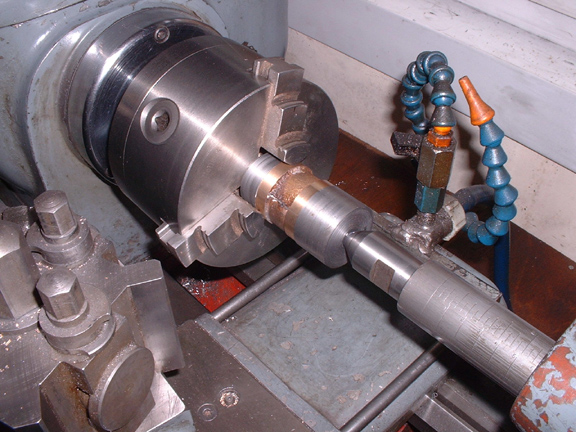

I had an attack of conscience last night and decided to do a proper job of the crankshaft bearings by boring them instead of cheating by poking a drill through. I've upped the size to 3/4", I never could understand why Stuarts specified 11/16".

Here's a pic with a story behind it. The article stuck up the bore is the 3/4" standard out of a nice boxed set I reclaimed out of a skip many years ago. Never pass up an opportunity.... These things always come in handy in the end.

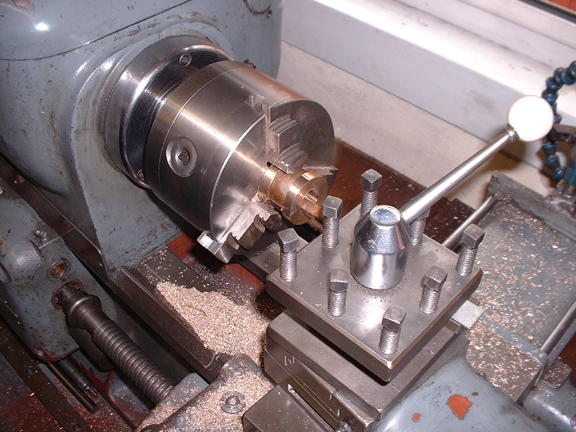

Next job was to cut the gutter out for the pedestal cap to sit on and location on the soleplate. This looks like a complicated setup but isn't actually, just a spacer behind the workpiece in the chuck to bring the bearing forward and a centered block with a 3/4 register on the front of it. Makes it a lot easier to set the bearing up central and gives it support whilst cutting the gutter. You can't use a mandrel because the bearing is split and only held together with solder, alright, it should be strong enough but I don't trust my soldering and why take chances? There is too much work in these little lads.... The setup makes it solid and you'd be surprised what heavy cuts you can take once you've got through the skin.

Here are the bearings, all bored and finished and numbered so that if they fall apart I know which bits match! Actually, I never bother to separate them because in effect they are bushes and the only time you need the split is if at some point later in the engine's life you need to adjust the fit of the bearings. Notice the lead block on which the bearings were rested to be marked. Handy thing to have about, soon made by melting scrap lead and casting in a dish. It gets used mainly as the backing for cutting leather or packings with a wad punch but is very good for jobs like numbering small items with punches because it gives a dead blow because being soft, there is no bounce. Looks as though I'll have to start fitting the pedestals to the soleplates and boring them 1 1/16" now.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |