| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 06/05/2007 : 07:10 Posted - 06/05/2007 : 07:10

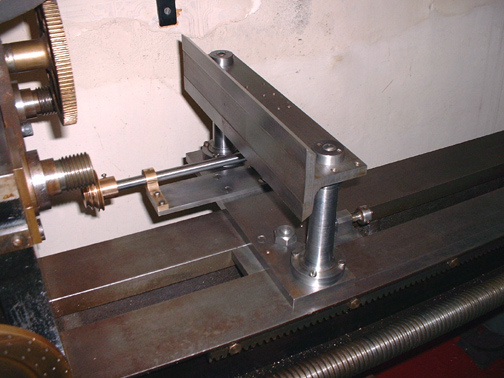

The motor problem on the 1927 lathe is kicked into touch until Delta deliver the ultimate solution so we move in on the 1950 lathe.

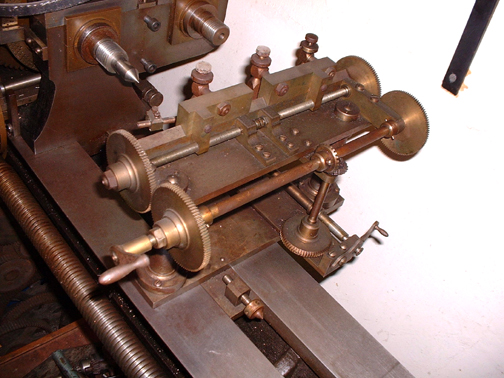

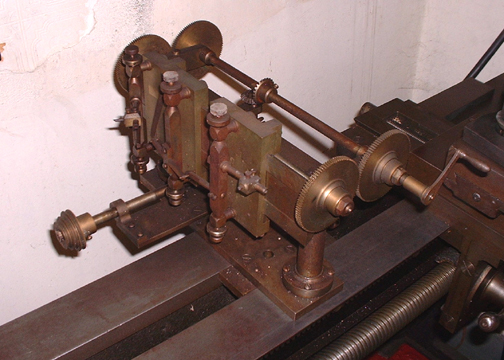

You'll go many a long weary mile before you see anything like this again. It's a medallion machine made some time in the 1950s by Johnny Pickles. I know it must be this date because it can only be used on the double spindle lathe. It's a copying machine for cameos, medallions or similar objects. Two identical chucks are mounted on the spindles and the far one carries the original, the near one carries the blank, usually ivory. The far tool holder carries a follower point and the near an identical cutting point. The theory is that as the lathe rotates the cutter follows the profile of the original and you end up with a copy. The first thing to do is get it all cleaned up and properly mounted, I'm making the holding down bolt at the moment. Then I need an identical chuck to match the one I have. I'll put a separate pic up of the geared chucks. One thing that strikes me is that flash photography makes everythin look rustier than it is. True, all this stuff had a hard life but is actually in better nick than the photo shows.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 06/05/2007 : 07:44 Posted - 06/05/2007 : 07:44

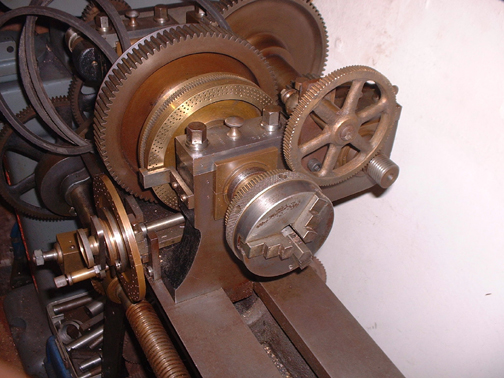

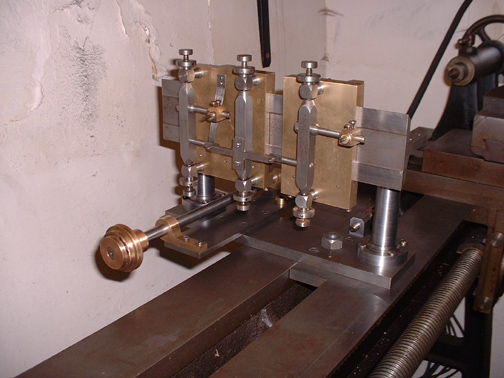

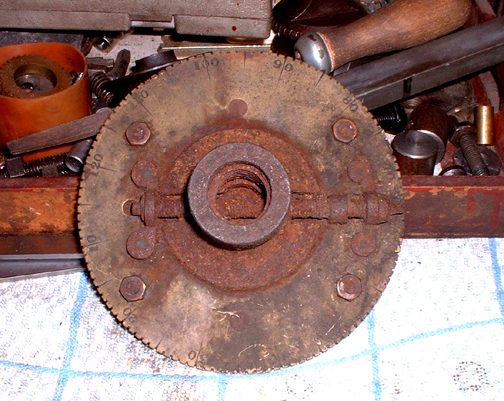

Hears the surviving geared chuck mounted on the lathe with its connecting gear wheel which keeps both spindles in synch. I am short of a 4" Burnerd scroll chuck identical to this one so if you've got one anywhere I'd be very pleased to hear from you.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 07/05/2007 : 17:10 Posted - 07/05/2007 : 17:10

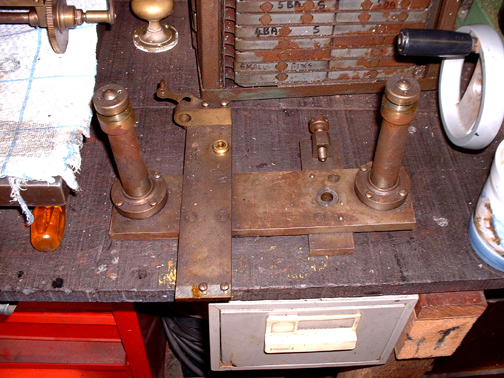

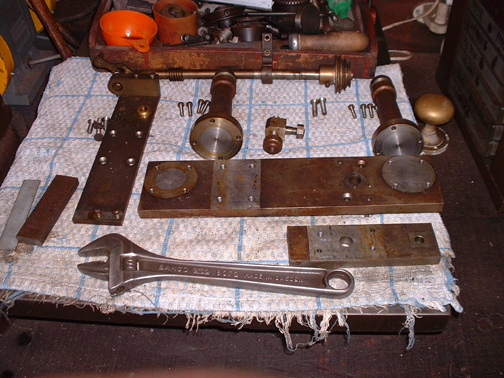

My dad always taught me that if someone could put something together, he could take it to pieces. He was right, however, when you're dealing with something which is quite complicated it's a good idea to procede carefully, do some record pics and be as methodical as you can. Here's the medallion machine partly stripped, I shall do the steel base and pillars first. The screws are laid out separately because even though some are the same size, they are all hand made and need to go back in the right place. Once again I'm learning about the way Johnny's mind worked. Like all good fitters, the finish is all on the top where it can be seen, the bottom is just as it was when it came off the shaping machine, no point filing that up and polishing it.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 10/05/2007 : 05:10 Posted - 10/05/2007 : 05:10

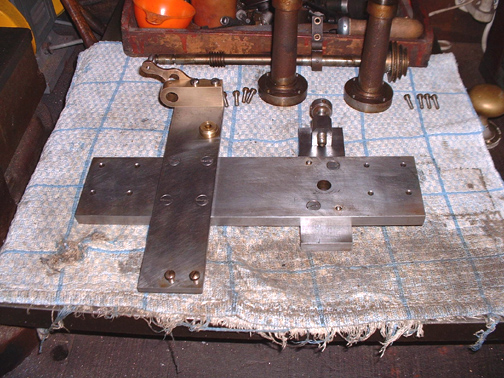

We've made a start, wonderful what a difference a bit of TLC can make. My way of recovering something like the original finish on steel is to start with an ordinary stainless steel pan scrub dipped in very thin oil followed by a polish using very fine, well used wet and dry paper soked in thin oil. Depending on the depth of rusting, in this case not bad, this gets you back close to the original finish without any scratching. For brass, just very fine wet and dry with oil. The trick is slow and steady and make sure you miss nothing because it stands out like a sore thumb when you have finished.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 10/05/2007 : 17:47 Posted - 10/05/2007 : 17:47

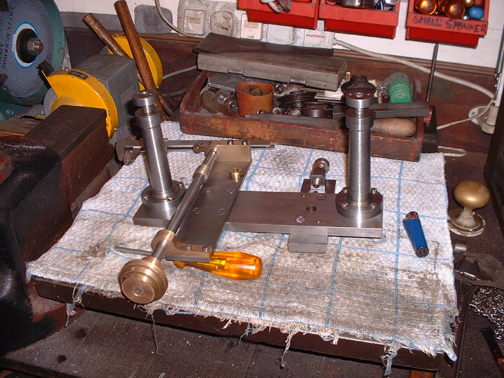

Bit further. The pillars were badly rusted and I had to put them in the lathe and give them a light skim and a polish. Not quite as good a finish as Johnny but definitely clean and shiny..... Now for the brass bits.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 11/05/2007 : 16:59 Posted - 11/05/2007 : 16:59

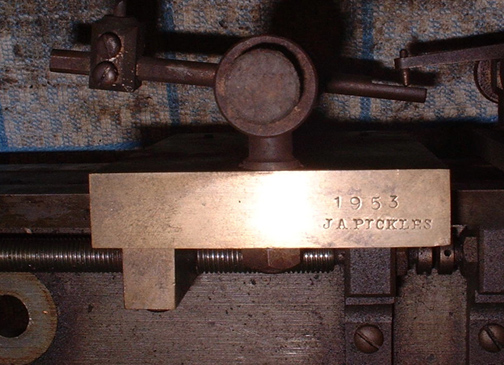

We press on..... First nice thing today was that after doing some reference pics and stripping the medallion machine down, hidden by the dirt, under one of the cutter slides, was this inscription. Quite imoprtant really in archaeological terms because whilst I was convinced Johnny had made it, here is the proof and the year as well. Nice thing about this is that it shows the 1950 lathe was indeed made about that year as he had to make the lathe before he could make the medallion machine.

The foundations are clean and on the lathe.

The bench is a litter of parts and screws..... Nice thing is that when I stripped the first slide I found that all the fulcrum blocks are numbered on the block and the back plate. Well done Johnny!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 12/05/2007 : 17:36 Posted - 12/05/2007 : 17:36

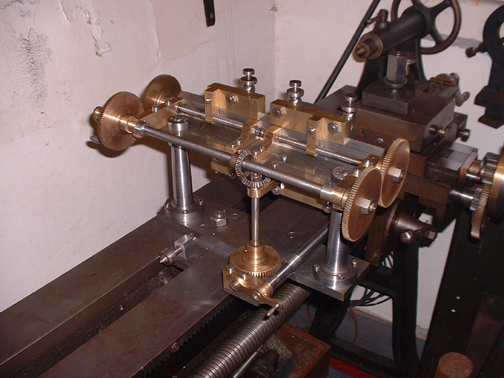

About half way there..... Looking a bit different!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 13/05/2007 : 17:28 Posted - 13/05/2007 : 17:28

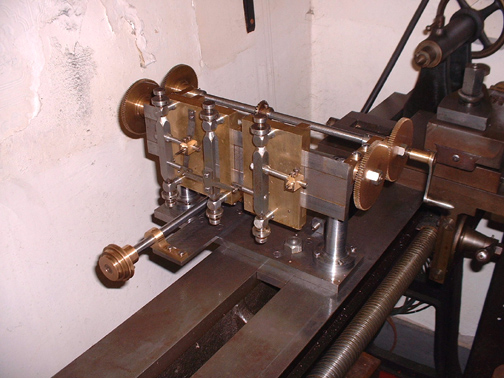

Back from the grave. The madallion machine is finished and in perfect working order. They say a thing of beuty is a joy forever. I reckon that beauty plus utility beats that...... I think Johnny would be pleased.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Ringo

Site Administrator

3793 Posts

|

|

Posted - 13/05/2007 : 19:08 Posted - 13/05/2007 : 19:08

Wonderful, it looks like it was made yesterday!

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 14/05/2007 : 05:54 Posted - 14/05/2007 : 05:54

Thanks Ric, I must admit I'm pleased with it. Here's the next one...

This elliptical chuck never fitted the 1927 lathe but as it's a re-make not a refurb I can make it to fit. It's so badly rusted that it can't be brought back but the brass bits are OK. I think it could be an old Holtzapfel chuck.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 14/05/2007 : 17:34 Posted - 14/05/2007 : 17:34

This gives an idea of the state of the chuck. It has been somewhere very wet for a very long time. Completely rusted up. This is a re-make not a refurb.

Taking it to bits without damaging the good bits was a bit of a challenge. The interesting thing is that the nose of the lathe it was made for was threaded one inch Whitworth and the lead screw is five sixteenths, 20TPI so it isn't a Holtzapfel chuck because as far as I know they were metric threads. Could be a Fenn or a Birch? It's very old.....

First thing we need is a new boss/chuck back. Here's the blank roughed out, some proper machining tomorrow.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 15/05/2007 : 06:07 Posted - 15/05/2007 : 06:07

I was sat watching TV last night and a thought struck me.... I grabbed some thread tables to check and a 3/8" BSF is 20tpi. I think the rust has thinned the leadscrew down, mine is going to be 20tpi and 3/8 because it means I can rough the thread on the lathe and then run the BSF die down it to get a better finish. Easier, quicker and a better job because I can use silver steel for it.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

belle

|

Posted - 15/05/2007 : 22:51 Posted - 15/05/2007 : 22:51

I have been popping in from time to time, Stanley, and admiring all the nice shiny things you are doing in the shed... and I really felt i should keep quiet because I know nothing of these things...but it has been thrust under my nose so often, with pics coming up all over the place... so I am bursting to ask you...what does a medallion machine make... i have visions of you now, bedecked with necklaces, each one sporting a big shiny disk that nestles in your chest hair,like a gong, as you murmer approvingly "My, am I glad I got this medallion machine up and running...."

Life is what you make it |

marilyn

|

Posted - 16/05/2007 : 01:05 Posted - 16/05/2007 : 01:05

Oooooo...I see it too!

And he has a bandana tied around his head....and he keeps saying "Yeah, Baby"....

get your people to phone my people and we will do lunch...MAZ  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 16/05/2007 : 06:38 Posted - 16/05/2007 : 06:38

You're right Belle. If you look through the pictures you'll see that the 1950 lathe has two spindles whereas a normal lathe has one. This means you can have two identical chucks on, one on each spindle and geared together so they rotate in synch. The medallion machine has two identical tool holders, one for each chuck. What you do is mount a madallion or cameo in one chuck and an ivory or blackwood blank in the other. A rouded pointer follows the contours of the original and the motion of the cutting head ios transferred by a system of levers to the other cutting head which has a sharp tool in it. As the heads are traversed across the face of the workpieces the shape of the original is cut into the blank piece and in theory you finish up with a perfect copy. I've never used it and I think there would be a lot of lost motion but where I can see it being very good would be if you had a hard wax blank which would cut easily. You could encase the wax copy in a plaster of Paris casing and then melt the wax out and cast a bronze replica. I might give this a go one day....... However, I won't be wearing it! Don't ever be frightened of commenting, I know people are watching because of the hit count but there are very few comments.... I welcome them. This chuck I am on with now is a bit of a task, I've never seen anything so rusted up. A shame it was allowed to get like that but by the time I am finished it will be a good tool again. Let's put it this way, it would fetch a good price on Ebay......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |