| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

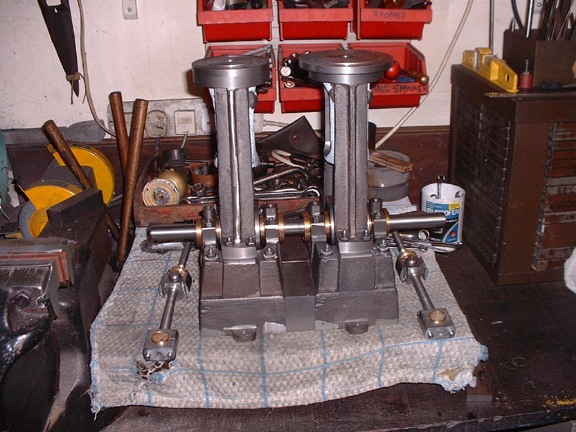

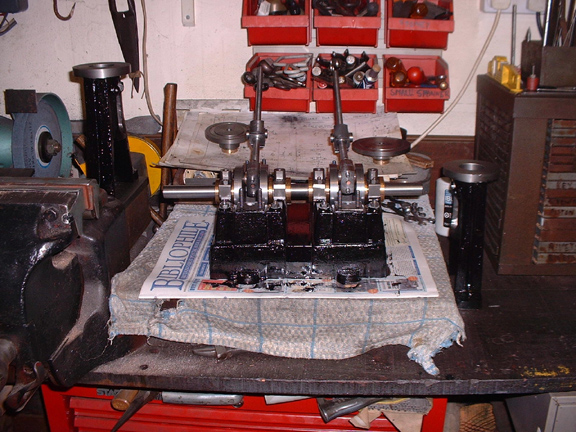

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 28/09/2007 : 17:24 Posted - 28/09/2007 : 17:24

Well, it took longer than I thought. Everythig fitted and lined up but I had to do a lot of easing and modifying to get it perfect. That being said, by dinnertime we had everything right, free running and play well within limits.

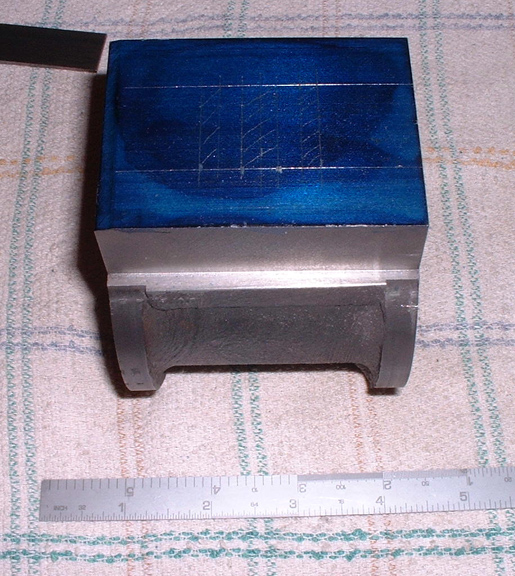

I've spent the afternoon on the next single engine. As with the other I had to mill out an aperture in the bed plate to give room for the bolt heads on the marine end. Then I sorted the shells out for the marine end, rivetted the bottom shell in place with a copper rivet and istalled it. Problem is it was a perfect fit and hence, a bit tight. What to do? I didn't want to pull it down again so I flooded it with T-cut, that's right, the stuff you use on your paintwork on the car to restore the colour. It's actually a very fine abrasive. Once the T-cut was in the shell I spent an hour working the bearing backwards and forwards and then finished off by flooding it with oil to wash the abrasive out. It's a lovely fit now, just a bit on the tight side but it will soon run in with some compressed air on it. Enough for the day, I'll finish it tomorrow. I think I was a bit optimistic with my one engine a day..... Never mind, time doesn't matter, just the quality of the fitting.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 29/09/2007 : 14:28 Posted - 29/09/2007 : 14:28

You won't find this one in the Boys Own Book of Steam-engine Building! I finished building the bottom end of the second engine this morning and when I got it knitted together it was too tight to run. This tightness wasn't down to any one cause, it was a combination of new surfaces and good fits so there was no point in taking it down and easing everything because when it was run in it would be too slack. So..... bolt it to the bench and fit my engine running in aid, a good size hanle that's comfortable to hold and turn it until the initial roughness wore off, aided with a dab of T-cut in the oil. An hour later all was well, turning so freely that when you let it find its own position the weight of the con rod and crosshead took the shaft to bottom centre.

By 13:00 this was the line-up. Two engines fitted up at the bottom end, two to go if you rate the compound as two. I've decided that's enough for the day, it's Saturday after all! So I think I'll have a shower and do a bit of slobbing. Jack agrees......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/09/2007 : 08:25 Posted - 30/09/2007 : 08:25

I've spent a lot of time thinking about piston fitting. The Stuart way is a taper on the rod and a nut.... I might even do it that way but I can't help thinking that instead of following full-size engine practice there might be a better way......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/09/2007 : 11:59 Posted - 30/09/2007 : 11:59

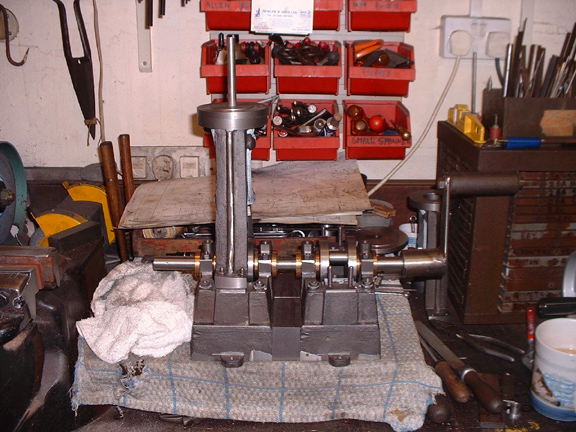

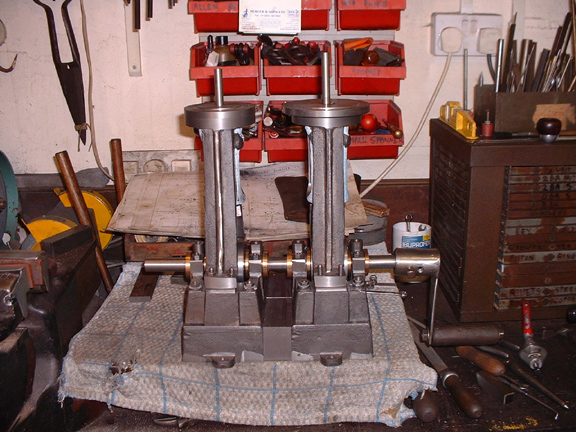

Funny morning. I was up early to watch the Grand Prix at Fuji and what an interesting race! All the chores done, Jack walked, a big breakfast and all I wanted to do was have a sleep so I nodded off in the armchair. By 11:30 I was back in the world of the living and decided to take Jack to Letcliffe and have the afternoon in the shed. So, I staggered in there with the double engine (it isn't half a weight!)

#

So, here's the size of the rabbit. Bit impressive isn't it. I had to step back to get it all in.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 30/09/2007 : 16:22 Posted - 30/09/2007 : 16:22

Never got in the shed, I started baking instead! That's one advantage of being managing director and labour of the Barlick Steam Engine Manufactory.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 30/09/2007 : 21:23 Posted - 30/09/2007 : 21:23

Stanley

I'm on early turns this coming week, so I had a lie in and watched a recording of the "live" Grand Prix coverage when I got up. As you say, turned into a pretty interesting race. Bet the "Highlights" viewers don't get treated to Mark Webber's views on rookie drivers though! Always amuses me when they stick a mike under a driver's nose and say something like: "you've just crashed out of your best ever race, how do you feel about that?" Trust an Aussie to tell 'em what he really thinks!

Malcolm

|

panbiker

|

Posted - 30/09/2007 : 23:32 Posted - 30/09/2007 : 23:32

I watched a couple of fascinating programs on UK Documentary channel on sat TV this afternoon, two british blokes, 3 including the electrical wiring guy refurbishing a 1945 Comet tank, fantastic stuff, heavy engineering and the like. They have been at it for 12 years and are refurbishing back to original spec. The second program (i think it's a series) showed an american guy who has sourced and recovered a German Panther tank. The tank was abandoned in a river in Poland where it was knocked out in 1945. They have taken it back to the States, it's one of only 5 known surviving examples in the world, pretty corroded after 60 odd years at the bottom of the river. The american guy is a billionaire and has one of the largest collections of heavy armoured hardware in the world, more than 200 tanks that he has financed restoration on. They reckoned the restoration costs for the Panther will run into the millions.

Same principals as you Stanley, just a bigger shed!

Ian  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/10/2007 : 05:24 Posted - 01/10/2007 : 05:24

Yes, Mark was quite direct wasn't he..... As for the blokes restoring tanks..... I wonder whether anyone ever did a JS3..... I always remember how surprised Guderian was outside Moscow when the Russian tanks came over the hill and it was too cold to start the engines on most of his.... When I was in Berlin with the 17pdrs we always reckoned we could knock out anything the Americans or French had but we knew we'd be in trouble with the T34s and the JS3. We decided that if ever they did come we'd go for the tracks.

Strawberry and apple pie was a disaster, now I know why people don't make them! Back into the shed......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

tripps

|

Posted - 01/10/2007 : 13:58 Posted - 01/10/2007 : 13:58

Thanks Stanley for the trouble you are going to in keeping us up to date with this project. They are starting to look like something I recognise now, but I still haven't worked out where the coal and the water go! The items in the background are interesting too, for instance, a bottle of Lamb's Navy Rum, and industrial quantities of Ibuprofen tablets. Are they by any chance related as they say in the 'eye'?

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/10/2007 : 17:23 Posted - 01/10/2007 : 17:23

Ahh, it's a window into my world David. I've taken a lot of Ibuprofen over the years for my back but of late have stopped taking both it and aspirin. I was taking them as a preventative measure but thought I'd try life without them. Turns out that many of the pains I was getting nust have been as a result of taking the pills. The rum is standing in for the single malt that usually stands there because Doc gave me a bottle of Pussers Rum and I thought I'd better drink the cheap stuff. I always start the day with a dose of Cod Liver Oil and a slug of whisky (rum at the moment) As fior the big packages of pain killers, my mate Martha brings them over for me from the States where they still trust someone to buy 350 tablets at a time for $6. They are a rip-off here in the UK.

Both beds milled out for the marine ends and the left hand engine is built up and eased off. Everything is a nice fit. RH engine is on the cards for tomorrow. David, these are just the steam engines, they need a separate supply of steam from an independent boiler. This engine would need a boiler about three feet high and 18" in diameter but could drive a 20foot launch on still water. The small ones for the kids will drive a 14ft boat.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 02/10/2007 : 16:07 Posted - 02/10/2007 : 16:07

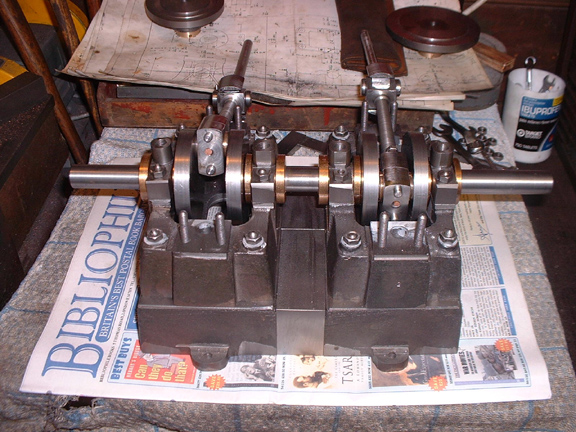

By 10:30 this morning the RH engine had flown together, no problems at all. I did all the tiddly bits, drilling and tapping the standards for the crosshead lubricators and making sure the gland nuts were fitting nicely and not fouling anywhere.

I thought I'd let anyone thinking of following me see the bottom end for the last time.... In case you're wondering, the copper studs in the bottom of the narine ends are the rivetted tops (or bottome!) of the copper rivets which locate the bottom brass and stop it moving. If it did the oil hole in the top brass wouldn't be in line.

By dinnertime I'd finished the painting, not my favourite job, but I know the engines will look better with the castings painted. There will be no more painting! We're getting near having three engines now, the bottom ends are fitted. The order of play from now on is make the valve ports in the cylinders, drill the steam passages, all the drilling and tapping for the holding bolts and make the actual valves and the valve gear. The finishing items will be making the tiddly bits, drain cocks, steam valve, lubricators and pipework. Plenty to do yet but I'm getting that nice feeling that there is less to do than I have done already.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 02/10/2007 : 16:46 Posted - 02/10/2007 : 16:46

Steam passages in small engines..... The Stuart castings usually have the steam passages in the walls of the cylinders cast in and I have never liked them, I'd rather drill my own and get them as big as possible. Assuming you have a boiler that can deliver all the steam you want, the bigger the steam passage between the valve seat and the cylinder, the better. I shall spend a lot of time working out just how big I can get away with. Another place where people often slip up is not making a big enough aperture at the end of the cylinder to connect the passage to the bore. I've seen them just filed out and far too small. Again, I shall give some thought to this. The bottom line is that the easier the live steam can get in and the easier the exhaust can get out, the better the engine will run. Newton was a master in this department and I shall be trying to see if I can get anywhere near him. To give you an idea. When Newt and I made two identical engines in tandem, on the same compressor, his did 500rpm and mine only 300rpm flat out..... I can see me hiring a compressor later.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 03/10/2007 : 07:42 Posted - 03/10/2007 : 07:42

Couldn't resist it.... When the paint had taken its initial set last light I shifted the double engine back in the kitchen with its mates. It's warmer in here and the paint will harden quicker. I've had this paint for over 30 years, Sanderson's Diamond Black polyurethane paint. Takes a week to harden but a very tough finish. It was used (in white of course) for repainting baths. You don't use any undercoat, just slap it on and if you want a better finish on a flat surface, rub it down and paint on top. I used to use it as chassis paint on wagons. Paint taking so long to set is no prob. All the work for the next couple of weeks is in the cylinders and valve gear.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

frankwilk

|

Posted - 03/10/2007 : 08:48 Posted - 03/10/2007 : 08:48

Stanley

You will have to start charging Lambs for advertising, you do know these pictures do go all around the World !!!

Frank Wilkinson Once Navy Always Navy  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 03/10/2007 : 17:44 Posted - 03/10/2007 : 17:44

I've nearly emptied the bottle Frank, we'll be back on single malt shortly!

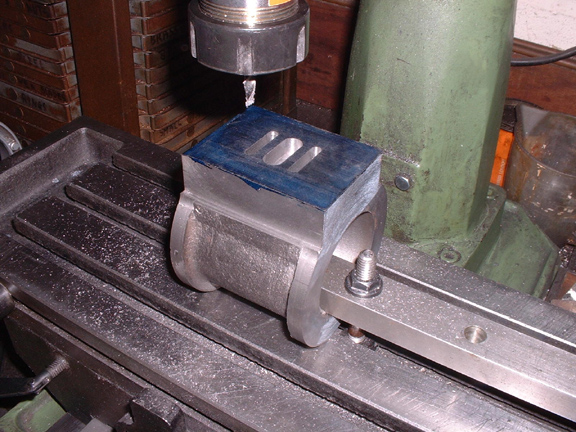

Today has been a good example of the savings in time doing 4 engines at once. It took me 3 hours this morning to design the valve ports (remember I have no drawings for these), check all my measurements, do a drawing and then get set up on the V miller, sharpening both cutters etc.

By Letcliffe time I had cut the ports in the first cylinder. By 17:00 I had done all the others, 3 cylinders in just over two hours, including the large one which is essantially the same as the small ones except that the ports are wider. Steam passages tomorrow.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |