| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

softsuvner

|

Posted - 04/08/2008 : 21:45 Posted - 04/08/2008 : 21:45

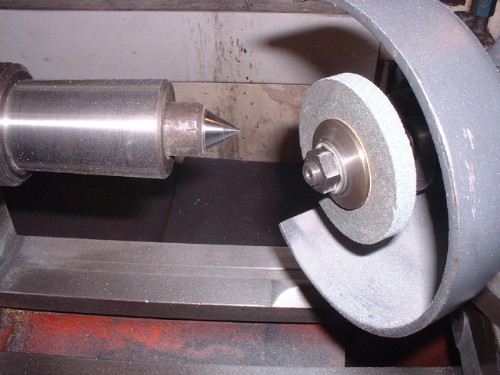

Stanley

Fascinating piece of kit, a tool post grinder was one of the perennial "make it yourself" projects in Model Engineering books. Must admit, like you, I was always wary of getting grinding wheel dust on the lathe slideways. Certainly puts a fantastic finish on. I could never think of anything to use one on myself, but the racers I knew who liked to play with cam shapes would have welcomed one, if you saw some of the lash-ups that people used!

Malcolm

|

Bodger

|

Posted - 04/08/2008 : 23:12 Posted - 04/08/2008 : 23:12

Stanley, curiosity, was the wheel and the work piece rotating in the same direction ?, ie, the far side of the wheel cutting against the rotation of the work piece?.

"You can only make as well as you can measure"

Joseph Whitworth

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 05/08/2008 : 07:27 Posted - 05/08/2008 : 07:27

Good question Bodge. The lathe is turning the normal wat and if you look at the sparks you'll see that the wheel rotates in the same direction at the point of contact. Of course the peripheral speed of the wheel is so high that the net effect is to grind the workpiece. Malcolm, I love this grinder, I wish I'd sorted it out a long time ago. I haqve to say that the Dumore Company produced a goody, it's a beautifully built piece of kit and the balancing of the various components must be spot on, no vibration and it just whines at you! Fearsome speeds though. I'm glad it is a high quality wheel enclosure. Can you imagine what would happen if the wheel burst? Just worked the peripheral speed of the 5" wheel out, it's just short of 6,000 ft per minute. I used a higher traverse speed on the mandrel and the finish is still good. I shall do the other this morning...... I have to admit that I have been working out other uses for it. One that came to mind is reducing the shanks of large drills do they will fit a 3/4" chuck. Cleaning drill shanks up after a slippage. There is of course the small matter of internal grinding. I have all the mandrels and stones and the ability to go up to 45.000rpm.......

Many years ago Newton looked on indulgently as I wrestled with the problem of a badly worn scroll chuck, 3 jaw SC of course, that was badly out of truth. If any of you have ever thought about this, it's a minefield and I believe, impossible to rectify with any accuracy. However, if I had a bad chuck I'd be tempted to have a crack at it, I'll bet I could make an improvement with this tool...... Ideal of course for cleaning up scarred jaws on 4 jaw independent chucks and I suspect a goodie for drill chucks as well. Cleaning up scarred internal tapers on Morse adaptors? I have a set of Morse Taper reamers but there is a limit to what they can do.

A thought has just struck me..... At the moment my dead centre is a Morse taper adaptor that takes a no.3 cntre. Perfectly accurate of course but potrudes a long way. The dead centre doesn't need to be pot hard and so I could make a centre, geind it to a good finish and thread it for a drawbar and then turn the cone in situ on the lathe. It would give me another 3" between centres and be perfectly accurate.....

Isn't fitting and shed work wonderful. Always something to tease your mind...

Just for a laugh, give me your suggestions for setting up a defective three jaw for grinding. Let's have some fun. Who knows, someone out there might have an answer. Newton and I never found it.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Bodger

|

Posted - 05/08/2008 : 12:54 Posted - 05/08/2008 : 12:54

Stanley, how about a flexible loop of srong cable around one of the outside step of the jaws, this would allow the jaws to reach their individual out position, then grind one of the external step range to give an accurate OD, afterwards use an accurate ring to hold the jaws in the open position, and grind the internal clamping faces?

"You can only make as well as you can measure"

Joseph Whitworth

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 05/08/2008 : 18:07 Posted - 05/08/2008 : 18:07

You're on the right lines for the external faces but it's the internal faces that are the problem. If you use a hoop on the outside the scroll face that is exerting the pressure is not the one that is doing it when you are gripping internally and it is the position and profile of that opposite face that governs the concentricity of the jaws. Keep thinking, who knows, you might crack and age-old problem.

More of the same today, I did the big expanding mandrel and it was miles out, even worse than the other. Not only was it not concentric but the faces weren't parallel. It is better now! While I was on with it I was thinking and the only scenario that can explain the fact that on both mandrels one blade was completely out of sync with the other two is that the blade has been swapped from another, identical mandrel. I can imagine a situation is a dhop about to be closed and auctioned off where two turners with identical kits could get together and swap a blade so making sure that whoever got their tackle would have a problem. This isn't as far fetched as it sounds. I have come across industrial sabotage once or twice in my career. At the dairy at West Marton, the bloke in charge of the bottling and capping plant had the flap which actually pressed the foil cap on before it went under the sealer weighted with a couple of rubber bands to make it work smoothly. When he had a day off he used to take the rubber bands off so the capper would miss and give trouble. My mate Ted Lawson soon twigged this and fitted his own rubber bands but the idea was for the management to notice that the plant ran better when the regular man was on it. Crafty bugger eh?

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 05/08/2008 : 18:13 Posted - 05/08/2008 : 18:13

PS. Another old name for you. This mandrel was made by W G Le Count, Norviak, Connecticut, USA. The Le Count expanding mandrel is still made by Gleason Asia Co. in Tokyo. I wonder if Le Count invented it and held the patent?

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Furry mad kat

|

Posted - 06/08/2008 : 08:32 Posted - 06/08/2008 : 08:32

I always wondered what men do in their sheds. We have his and hers sheds. His is large and prominantly placed. Mine is tiny and hidden in the corner. His is called the Cave and is full of mystery, mine's falling down and houses everything he can't fit in his shed........I think he's building two tone horns for his MGY he's restoring! Mmmmmm

FMK

FMK

Count your garden by the flowers, never by the leaves that fall.

Count your days by the golden hours, don't remember clouds at all.

Count your life by smiles, not tears, and with joy on every birthday.

Count your age by friends, not years.  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 06/08/2008 : 10:37 Posted - 06/08/2008 : 10:37

Pussy, have a furtle round, you never know what he might be up to in there!

You'll all be pleased to know that I have worked the grinder out of my system. I've got fed up with the muck and the dust! So the grinder is packed away in its box and stowed out of the way under the 1950 lathe. The transformer is back in the reserve store in the little shed in the back yard and I have accurate expanding mandrels. I have to own up that my last job this morning was to regrind my centres. They weren't bad, I'v never used them as centre punches..... but it was nice to set the grinder up properly at 30 degrees and do a tool room job on them. There was one more....

This centre has defeated me for over 30 years. If you look carefully you'll see it has darker metal on the tip. This is quite a rare beast, a carbide tipped centre and I have never had a green grit wheel for the Clarkson grinder so it has just sat there. I had a furtle in the treasues and found I had a green grit wheel that came with a set of masonry drills that had enough lead packing in the centre to bore out to 3/8". So I bored it, checked that it was OK for the speed (up to 7,500rpm and it was running at 4,500 so that was alright), dressed it until it was true and concentric and attacked the carbide centre. We now have the hardest centre in Barlick, ground true to 60degrees included. Thing that I've often wondered about is how it got worn out of centre and why have one in the first place? I would have theought that anything hard enough to demand a tipped centre would be too hard to turn. Anyway, it's a useful addition now. The next job is to walk Jack and then have a shower to get rid of the dust, amazing how it clings.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 07/08/2008 : 06:16 Posted - 07/08/2008 : 06:16

Public Service Announcement. Stanley had his shower and has washed his clothes. I think we have got rid of the grinding dust...... Useful process but not very healthy without a powerful extraction system.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 07/08/2008 : 07:48 Posted - 07/08/2008 : 07:48

Stanley

Now we can see why your toolpost grinder was in such good nick, it only needs to be used once every decade!

All my fixed centres need truing again, never seemed to be able to stop them "picking up" a little. Years ago I bought a "live" centre which is a blooming useful piece of tack for most between-centre jobs. Made by another old name, one I am now very used to seeing every day .... Skoda!

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 07/08/2008 : 17:30 Posted - 07/08/2008 : 17:30

Malcolm, Skoda is a very old name and a good manufacturer. The biggest horizontal borer I ever saw was made by them and a nice bit of kit.

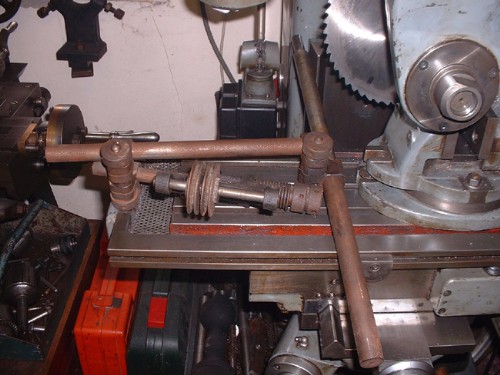

It'sa time I did something about the overhead drive for the 1950 lathe. Here's the rig up for the tension arm and the pulleys.

Here's the unit itself. First thing is a good clean up. No stripping down as it is in basically good nick. My biggest problem is to find a sky-hook for it. A plasterboard cieling isn't strong enough. Much midnight oil will be burned on this one!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 08/08/2008 : 07:30 Posted - 08/08/2008 : 07:30

I think I might have come up with a solution to the sky hook problem. A bit of investigation and ingenuity is called for...... This problem is going to be solved! More later .........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 08/08/2008 : 17:41 Posted - 08/08/2008 : 17:41

Not the most eyr-catching pic I have ever posted but it's a small triumph for an old bloke that couldn't find a handy sky-hook. I cut a hole in the ceiling and had a look and lo and behold I found some 3X2 studding I didn't know was there. So, a bit of angle iron plugged to the wall with 3/8 rawlbolts and 4 4"X10 screws driven up into the studs and we have a solid base to hang the Mardrive on. Now I have to do a bit of studying to get it up in a place that will give me a drive but not one where I'll bang my head on it every five minutes! I'll admit we're a bit short of headroom and this is, as they say, pushing the envelope a bit. One thing is certain, this is the last piece of machinery that can go in this space!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 09/08/2008 : 16:54 Posted - 09/08/2008 : 16:54

The older I get the more I appreciate the value of a slitting saw on the H Mill when you need to cut a piece of 1/4 plate. This is the base for the Mardrive and will be bolted onto the beam when it's done.

By 4pm the plate is finished and fastened onto the beam. All I need to do now is find someone daft enough to hold it up for me while I pop the bolts in. Luckily there's a big young lad called Ringo lives nearby........ Watch this space. Oh, and before you say anything, you're right it's not straight and level. Neither is the ceiling, but it doesn't have to be perfect as apart from the cord drive, it doesn't have to have any relationship with the lathe as long as the unit is in roughly the right place. Good job actually......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Ringo

Site Administrator

3793 Posts

|

|

Posted - 09/08/2008 : 20:45 Posted - 09/08/2008 : 20:45

Job done

|