| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

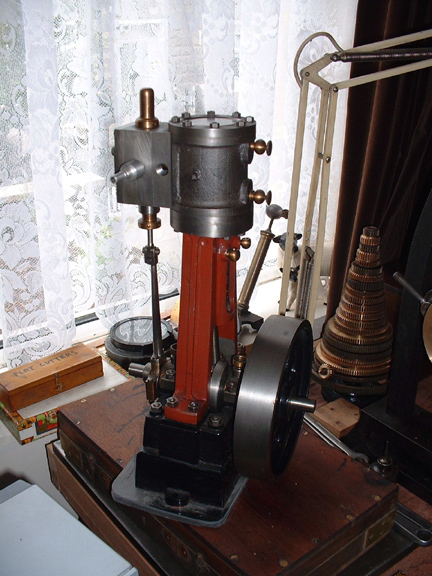

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 06/07/2007 : 15:44 Posted - 06/07/2007 : 15:44

Here's one I made earlier..... It stands about 18" high and if you've ever seen a Stuart 5A you'll see the family resemblance. The con rod is two and a half times the length of the stroke, the usual proportion for a mill engine and somehow it looks better to my eye.... The castings for this engine are about £850 now from Stuarts......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 07/07/2007 : 15:34 Posted - 07/07/2007 : 15:34

I wrote my article for the BET and walked Jack.... So I decided to get some castings out and let the dog see the rabbit....

The more perceptive amongst you will realise that I lied, I haven't got three sets of castings, I've got four! (Remember the Stuart price for these is £850 a time) These are just the box bed and the engine bed, there are plenty more in the drawer upstairs. So, we are really into mass production here..... Now this is good because I only need three for the kids so I have one spare and there's something else...

#

You may remember me mentioning once that I told Newton that the 2 1/4 inch bore cylinder looked a bit small on the engine and he agreed with me. He made a pattern and got castings made for a 3 1/4 bore Cylinder the same stroke (2") as the original. He had a set of castings made for me at the same time and I stowed them away in the old oak chest. So.... we can make it really interesting and fit the bigger cylinder to one of the engines. Not as big a modification as it looks because the only alteration to the basic design is the foundation ring for the actual cylinder and a bit more overhang on the crankshaft because the eccentric will be further away from the centre line. The difference in the bore makes a big change to the power. The standard cylinder gives about one and a half horsepower but the larger one will give much more. The area of the standard piston is 1.23 sqare inches, the larger one is 4 square inches so in theory this will give three times the power. Newton made quite a few engines with the larger cylinder and they seemed to perform OK. Problem is I don't know whether he beefed the crankshaft up. I'll have to give that a bit of thought. Plenty of muck shifting to do before we get there! First thing to do is clean all the castings up, get them machined to size with square faces.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 08/07/2007 : 17:34 Posted - 08/07/2007 : 17:34

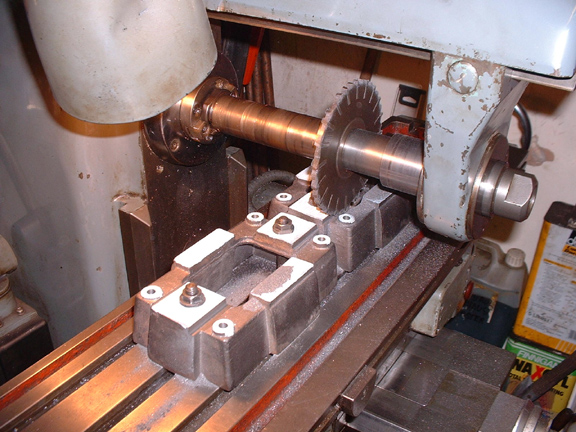

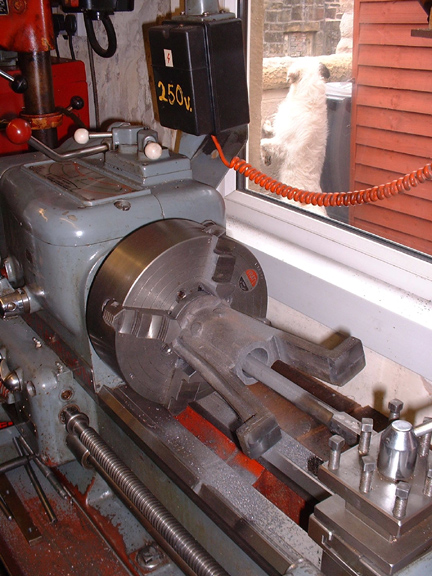

Did another article for the paper, walked Jack and then got stuck into some muck-shifting.... Here's the score, 4 box beds squared up, edges found and lugs machined. 2 foundation blocks ditto. Lots of CI dust and chippings vacuumed up, I think of Newton every time I clean up after dealing with one casting, if it was him he'd be up to his oxters in CI chips! Mind you, he did admiot that my way made it easier to work..... Lots of machining to do yet on the beds but the first thing to do is get some square faces so that some proper measuring can be done.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 09/07/2007 : 00:49 Posted - 09/07/2007 : 00:49

Stanley

I'm pleased to see that the sheds of Barlick have had a productive week: Ian is now sorted for his MOT, and the steam 'ammer is up and running! An awkward shift-pattern, and a frustrating hold up with "supplies", has meant that the only tool in action in my shed last week was the mastic-gun plugging up the holes that the monsoon had penetrated! Why is it that I can buy 1920's style beaded-edge tyres from stock; (choice of 3 suppliers) but the tyre for my 9 year old bike is on back order?

I was rather looking forward to some wisdom on painting the 'ammer, but I see that you have decided to move quickly onward to the 5a(s). Painting any miniature engine can be a tricky business. I don't know if you ever saw any of LBSC's own engines in the flesh....very interesting they were, but his paint jobs (with one exception) were nothing special. But then of course he would have argued that "'handsome is, as handsome does" and quite right too.

No Stuart images yet. I've tried to post a couple of things, but have come to the conclusion that my "dial up" connection is just too slow for the site to upload this side of Christmas - pulled the plug on the last attempt after 35 minutes (for 98k). I suspect "dial up" is being slowly eased out in the same way as analogue radio will be. A "dial up" connection also makes downloading any "picture-heavy" page a prolonged business. I have decided to bite the bullet and go for Broadband - so I may get to post some relevant pictures yet!

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 09/07/2007 : 06:54 Posted - 09/07/2007 : 06:54

Malcolm, getting BB will be like heaven for you. Send me pics if you want them loading on the site. There's only one way to paint a small engine or a hammer for that matter, take the thing to pieces and paint it, then re-assemble. Cherry Hinton used to do that and never run them again, it was all exhibition work. I am in this game for the pleasure of making things and given the choice between milling and painting..... Besides, the lack of paint means that my mistakes are more obvious, a good incentive for doing better. Your query about delivery times reminds me of the time I had a thump on the engine at Bancroft that I couldn't fathom. I rang Newton and he was with me in ten minutes. The MD asked me why it took three days to repair his car and I got instant response on an engine that was sixty years old (we found the fault and cured it the same evening). More milling today, no great accuracy or measuring, all I am doing is looking for parallels and squares, these castings aren't as accurate as Stuart's. I'll go through all the castings like that and then start again from the beginning with some marking up and proper dimensions. The trick first time round is to get to the right shape whilst removing the minimum of metal, you can always take more off but it's a hell of a job putting it back on! Besides, it gets a lot of the muck out of the way.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 09/07/2007 : 18:27 Posted - 09/07/2007 : 18:27

I finished facing the last two sole plates this morning and the afternoon has been spent marking the castings up for the location and size of the pads for the pillars and the bearing caps. I'd forgotten that all those measurements had to be adjusted from the Stuart drawings as our castings are different. I've drilled all the holes for the mounting bolts and also two holes on each casting to take the holding down bolts for milling the pads to size. These are covered up by the pillar feet when assembled so no problem there. Biggest asset has been the Clarkson tool and cutter grinder.... I can remember asking the bloke who persuaded me to part with £400 for it what the hell I needed a T&C grinder for. Am I glad I got it, it makes all the difference when you can whip a cutter out and touch it up. Dead easy of course if you are using the same cutter for a lot of cuts as the settings are already there. I always knew when I was buying tackle and machinery that it would all come in but I think that over the years a lot of people thought I was going over the top. Not so, you can't have too much good tackle, makes the job so much easier.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 10/07/2007 : 00:42 Posted - 10/07/2007 : 00:42

Stanley

Many thanks for the offer re posting, I will take you up on it. Would you believe that after all their pestering me for Broadband, Orange haven't managed to register me for an upgrade? I couldn't manage to do it through the net, so nipped into the Orange shop on the way to work. They couldn't sort if either, something about me being a hangover from Freeserve, now I will have to ring a call centre goodness knows where.

When you say Cherry Hinton, do you mean Cherry Hill (nee Hinds) who has made all those amazing award-winning steam models?. If BELLE is watching we should emphasise that it is MRS Cherry Hill, a lady model engineer! I've had it easy on bike paintwork for some time courtesy of a smashing chap who ran a stove-enamelling shop at Long Eaton. Now he has retired nobody seems to do stove enamelling any more (Health and Safety no doubt).

Over the years I have seen several Stuart 5a engines in steam launches, always described as "modified". Presumably with beefed-up bearings, lubrication and maybe Newton's "big bore" conversion?

I've just remembered, Cherry Hinton was the sight of a famous boiler explosion, was that a Freudian slip Stanley?

Now I wonder if Orange at Mumbai are answering their phone at this hour...........

Cheers!

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 10/07/2007 : 05:30 Posted - 10/07/2007 : 05:30

You could be right..... I'll have to have a dig! I got mail from Malcolm this morning....

Stanley

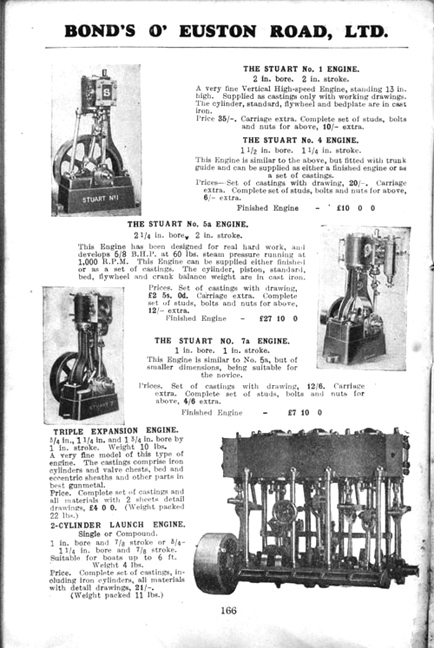

As per your kind offer, would you post the attached, if the scan is good enough please? I had planned to insert if in the Shed Culture thread as a "Stuart Price Guide" with the proviso that the prices might be slightly out of date!

Re my latest post on Cherry Hinton and the boiler explosion. Funny the way one's memory works. I have just found the reference in my first steam engine book, from 1960. In 1904 a Fowler Ploughing engine belonging to Pamplin Brothers of Cherry Hinton, Cambs, suffered a boiler failure at Linton, a few miles away. There is an iconic photo of the remains that has been used many times since. Perhaps you remember the place from delivering beasts in the area. If it was my Dad I would suspect a good Transport Cafe there!

Many Thanks

Malcolm

Thanks for that Malcolm, it will go up this morning. Funnily enough, I wrote to Woman's hour a few days ago. There is an exhibition on sheds and they were talking about it. I pointed out that it was a mistake to differentiate between women's sheds and men's as the best miniature engineer we ever had was a lady, Cherry Hinton. Her models were superb but once built she never ran them.

S.

[He's right.... I suppose this would be about 1930, prices were different then. Getting the admin out of the way, then walk Jack and into the milling again! Isn't it nice when the Crumblies keep themselves occupied......)

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 10/07/2007 : 05:35 Posted - 10/07/2007 : 05:35

You are right Malcolm, It is Cherry Hill. I wonder where I got Hinton from?

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 11/07/2007 : 00:48 Posted - 11/07/2007 : 00:48

Stanley

You were on the right track with the date. The Stuart page comes from "Bond's Model and Experimental Engineering Handbook for 1939-1940", price 6d (that's 5p to you youngsters). It is a thick little book listing an amazing variety of stuff from parts for model ships, planes, and railways, right up to bespoke locomotives in 5ins gauge.

I am not sure how the relative wage values compare for the time, but £27 - 10s for a completed Stuart 5a would represent about 25% of the cost of the cheapest car at the time - the Ford "Y". Interestingly that would make the Stuart 17/6d cheaper than the most expensive lathe in the Bonds book - the American 5ins Southbend. On the other hand if you wanted a flat-bed Drummond complete with stand and treadle, you would have paid £32!

If we equate those prices to a Ford Fiesta or a new Myford Super 7B lathe today, your completed engines will be worth.......................a fair bit!

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 11/07/2007 : 05:59 Posted - 11/07/2007 : 05:59

When you think about it, it's quite amazing how much time you spend making those expensive castings lighter! The horizontal mill came into its own yesterday. I set the beds up two at a time and squared up all the edges of the pads for the pillars and bearings and then turned the sole plates upside down and started on facing the sides under the bearing pads. I've done one, I'll do the other three today and post a pic. I'm doing eight hour days.... I suppose by the time I've finished these beds and soleplates there will be about 40 hours in them, call it £10 an hour for labour and add the on costs and you begine to see why engineering companies spend so much time tooling up to cut down on machining time. There was a bloke in Barlick once who had a little workshop like mine who got an order for I think it was twenty 5" gauge locos. Newton told me he got set up and started on them but had enough sense to give up shortly after starting, he realised that he couldn't make a wage. As I've said before, it amazes me how little these things fetch when you see them on something like Antiques Roadshow, they have no idea of the time that goes into them. Still, this is a labour of love...... Onwards and upwards!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 11/07/2007 : 11:54 Posted - 11/07/2007 : 11:54

Well here we are.... all the bed castings and sole plates machined and ready for the last bits of cleaning up. I finished the last three this morning. The nice thing about the Harrison is that it has automatic feed and while I was leaning on it watching it do all the work for me I got to thinking..... If you remember, the objective was to make three engines, one each apiece for my daughters and use the last set of castings to make another engine for myself with the bigger cylinder. Now I already have one engine that I made twenty years ago and all of a sudden I remembered a conversation with Newton. I happened to say to him that if he put two engines together on the same crankshaft and a bigger bed he'd have a serious launch engine. Next time he went to the foundry he got a bigger bed cast and made one, a serious bit of kit! The gears started to grind in the back of my head.....

Get the idea? I'm going to make two engines and add them to the one I already have and that's the kids taken care of. I am going to use the other two sets of castings to make a compound. I can join the two beds together using a spacer if necessary and mount one normal cylinder and one large one. That way I can have en engine to play with and add things like reversing gear, air pump and condenser if I feel like improving it. The result will be a serious lump that could easily drive a twenty foot boat......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 11/07/2007 : 18:09 Posted - 11/07/2007 : 18:09

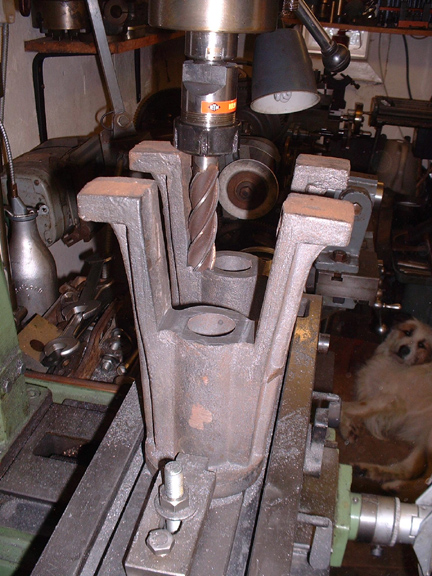

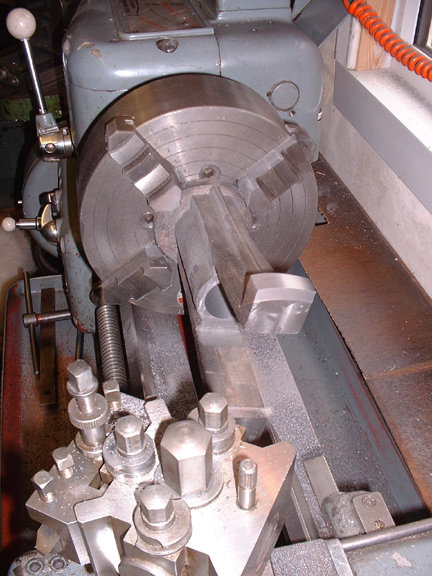

When I made my first engine all those years ago I didn't have a vertical miller and I can still remember the dodgy set-up I needed on the face plate of my big lathe (a Wilson 14" in those days) to machine the feet and other surfaces on the standards, They are little sods. Today it was fairly easy but still needed sharp cutters and fine feeds especially for the feet, too much extension and chance of a smash. kuckily I had a long milling cutter which I picked up somewhere and it was ideal for this cut down between the legs on the bottom face of the cross head slide.

Gently soes it on the feet, especially since one of them had a hard shop, the casting must have taken a chill.

All the standards have had the difficult cuts. I have taken the two beds and soleplates for the big engine upstairs out of the way. I shall machine all the castings together to get the advantage of one set up for four castings but after that I'll concentrate on the two small engines to make up the three for the kids. Good progress but lots to do yet!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 12/07/2007 : 05:35 Posted - 12/07/2007 : 05:35

I went to sleep last night trying to remember how I dealt with the standards twenty years ago. I've got a surface on the feet and so I'll fasten them down solid on the V miller table and then I can get a parallel surface on the top face. Then I'll put them in the four jaw on the lathe and find a centre. Then bore the crosshead slide, that should make it right angles to the top face and the feet. I think I'll make a mandrel to fit the bore and then I can do some cleaning up in the lathe on edges and faces. Then I have to face the underside of the top flange, that will be in the miller. Next the big slots in the cross head slide and one or two little faces for the lubricators etc to be faced. They are awkward sods and complicated but of course if the standard isn't perfectly central to the bed and the shaft the engine will never run properly. The joys of steam engine manufacture...... I've always said, if you want to really learn about engines, make one! These are exactly the problems the old fitters faced but on a larger scale.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 12/07/2007 : 17:46 Posted - 12/07/2007 : 17:46

I started the day by milling the top surface of the standards so that they were parallel with the feet. Then out with the most accurate chuck any turner has, the four jaw independent. The flat top meant that I could get the standard firmly and squarely bedded in the chuck and then I found the centre of the pilot bore.

The bore is finished and I am now turning the feet while I am sure the standard is perfectly central. This means that I have something to work off when mounting the standard which has to be perfectly square to the crankshaft.

Right, one standard bored, centred and perfectly square on the sole plate. The other three standards are ready for boring. When I have them all bored and centred I'll make a mandrel to fit the bore so I can mount them in the lathe and get to the other end to face it off to length and get a good register for the bottom cylinder cover....... But that's for another day. Slow work but no mistakes as yet......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |