| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

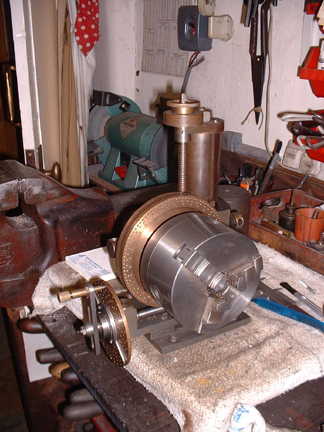

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

Invernahaille

|

Posted - 30/11/2006 : 18:55 Posted - 30/11/2006 : 18:55

Heyy Stanley. I like the lathe. Is it a twyford?

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/12/2006 : 06:14 Posted - 01/12/2006 : 06:14

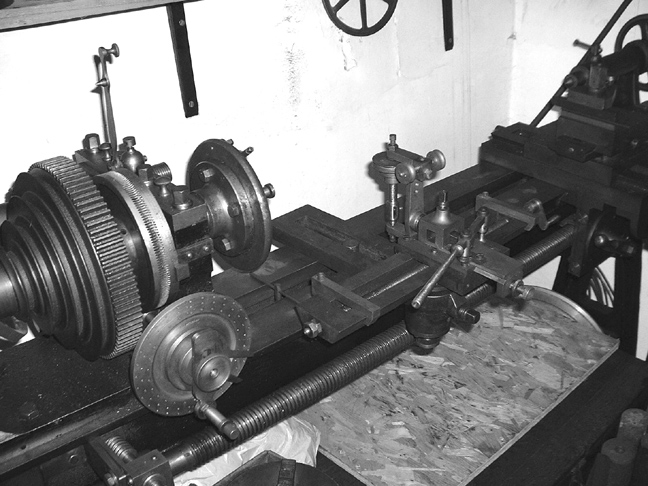

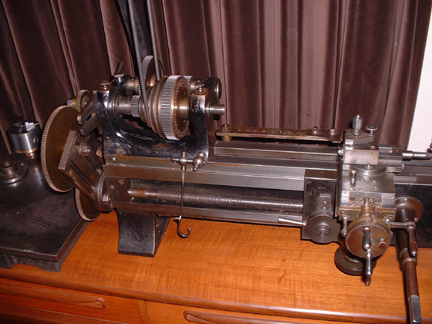

No Robert, see above. Johnny Pickles 1927 half size copy of a Birch Lathe from Manchester. Unique design, saddle is mounted on the front of the bed so you can have rise and fall on the slide rest tool holder. Dividing head in the headstock gearing. Very heavy bed for the spindle size made them very accurate. I've found more bits that fit it including a taper turning attachment for the back which can be fitted with shaped templates for turning curvilinear shapes. More about this later.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/12/2006 : 06:29 Posted - 01/12/2006 : 06:29

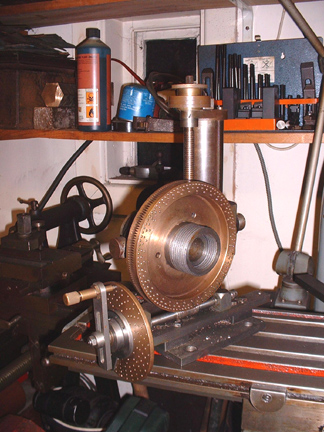

The search through the treasures to find lost parts for the 1927 lathe has persuaded me that it would be efficient to sort out the accessories for the 1956 lathe as well. This is probably the biggest Ornamental (or Complex) turning lathe in the world. Johnny built it in 1956 because the 1927 Birch which he had been using to mill clock gears was too small for the gearing of turret clocks and he was limited with the dividing gear in the head and had to use complex chucks. He built this lathe which is also a copy of a Birch Design basically. It is a normal geared screw cutting lathe but has tangential dividing gear in the head and an extra spindle which can be used with a medallion machine, more about that later. On the bed here you can see the Ornamental slide turning rest. When using this rest the work is held stationary in the chuck and is registered by the dividing gear in the headstock. Because it is tangential gear there is virtually no limit to the number of divisions you can use. As set up the OSTR has a horizontal milling head mounted on it. This carried a shaped fly cutter and was driven from overhead gear enabling you to make accurately divided horizontal cuts of any profile, this was dictated by the shape of the cutter. The depth of cut is limited by stops and the milling head advanced (equivalent of the cross slide on a normal saddle) by lever instead of screw giving a very good feel for the cut. This is the basic ornamental turning tool and using different milling heads and angles can produce a variety of work.

More later..... it gets even more complicated!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/12/2006 : 08:49 Posted - 01/12/2006 : 08:49

If you look carefully at the back of the bed you can see the latest addition to the Birch. It's a taper turning attachment that at the moment has a curved profile on it for cutting an incurve, say on a small vase.

The surface plate is one that I gave Newton about twenty years ago when I won two from Tommy Robinson's sale in Rochdale. I kept the 18"X24", this one is 12"X18", handy things to have around. Yhe lathe came with the Polish chuck of the left, in my treasures I found a Burnerd 3 jaw, a pin chuck, the pillar chuck for gear-cutting, you can see that it's been used for cutting a small gear and the cutter has overun into the body, quite intentional. In front is a chuck back which I'll have to find a four-jaw for..... All these were made for this lathe (3/4 inch Whitworth thread) and turned on it so they are dead central with the spindle. Onward and upward! I'm giving a lot of thought to driving it........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/01/2007 : 06:36 Posted - 01/01/2007 : 06:36

I've sorted through all the treasures now and found everything that I have that obviously goes with the Birch lathe. Johnny and Newton used it a lot on gear-cutting by using milling cutters driven by the overhead drive. Without the drive in use it is a very useful plain turning lathe for small stuff, almost down to watchmaking scale. I am going to fit it up with a motor in the front room and, horror of horrors, will use it for very small turning which makes hardly any mess. I shall make a tray for it out of 3/4 ply so I can contain the swarf and mount the electric motor sensibly. I doubt if I shall ever need a four-jaw chuck but I'm going to get one anyway so that the lathe is fully equipped.

Whilst digging I found some more accessories that fit the big 1956 ornamental turning lathe. These have been cleaned up and are easily accessible now. It's time I rigged up the drive to this lathe. I have an advantage over Johhny here as in another context entirely I found a separate overhead drive with its own motor and clutch. I shall fit this up to drive the milling spindle and find a way of mounting the drive motor for the lathe mandrel from below or at the back. Not as easy as it sounds because the lathe was designed to be driven from a lineshaft. I shall wait until the workshop has been re-roofed before I attempts this.

One good find was a Pickles variation on a Potts milling head. It had been converted into a universal dividing head with tangential gear and mounts nicely on the Harrison horizontal milling machine. It can be used either with a tailstock and mandrel or with a chuck mounted direct. I shall make a new threaded nose for it which takes the chucks off the Harrison lathe and that will fit me up for gear cutting on the miller. Doubtful if I will ever do a lot with it but it will be there for whoever inherits the workshop when I die! Time I did more pics........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 01/01/2007 : 06:53 Posted - 01/01/2007 : 06:53

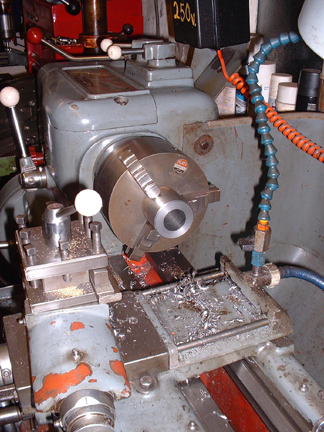

The dividing head. Because it has tangential gear in addition to a simple dividing plate it can be used for dividing a circle into any number of parts. Needs a bit of work as the dividing peg for the plate is missing but a very useful tool for gear-cutting or fluting.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

moh

|

Posted - 01/01/2007 : 11:08 Posted - 01/01/2007 : 11:08

Come on girls - let's have some photos of your sewing/knitting machines and other hobby paraphenalia

Say only a little but say it well  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 02/01/2007 : 06:06 Posted - 02/01/2007 : 06:06

It's time someone else posted on here, it's turning into Stanley's Shed Blog!

This tale comes under 'mugs for luck' I think..... There was nothing on TV last night so I went into the workshop to make a bit of muck. I decided to make a screwed bush for the Pickles dividing head that would accept chucks from the Harrison L5A lathe. First job was to take the original fitting off, measure up and identify the threads. No problem, my new bush needed to be threaded for inch and three quarters 8 threads per inch internal and two and a quarter at 6TPI external. So I sliced a piece of 2" stock off, banged it in the lathe and bored it.....

Quick and professionally done..... impressive eh?

I woke up this morning and the first thought that came into my head was 'Oh Shit!' I knew I had made the begginer's mistake of boring the bush for the overall diameter instead of allowing for thread depth. Deep Joy..... I decided to forget it, throw the bush into the stock pile and start again. I also decided to come clean and post a description of how stupid I had been. I mean, how could I have done that? I went in to do the pics for the post and after I had snapped the evidence I thought 'hang on a minute', that hole doesn't look like inch and three quarters! I measured up and happy day! I had made two mistakes, I had decided on the wrong diameter but I had also picked out the wrong drill, inch and a quarter instead of inch and three quarters. So I'm OK, all I need to do is bore a bit more out of the bush for threading size and then carry on in a professional manner! My Dad always said there was a providence that looked after drunken men and idiots.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Another

Traycle Mine Overseer

6250 Posts

|

|

Posted - 02/01/2007 : 06:10 Posted - 02/01/2007 : 06:10

Comrade, they say that confession is good for the soul but I'm sure that none of us would have spotted the error. I'll cleanse you of your sins and applaud your perfectionism.Nolic

" I'm a self made man who worships his creator"   |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 02/01/2007 : 06:31 Posted - 02/01/2007 : 06:31

I think it's funny when you make a mistake like this and even funnier when you find out you've made two and they cancel each other out! I've done it befoire, i HAVE ALWAYS HAD A PROBLEM GRASPING [bugger caps lock!] reversals like this, I think I've mentioned before that I am hopeless at translating the pattern for a casting to the mould because everything is reversed. Hard to explain but it's a blind spot I have to live with..... Having said all that, the mugs have won in the end, the bush will be OK! Thank you for the absolution........

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 02/01/2007 : 17:35 Posted - 02/01/2007 : 17:35

Now you can see what I have been on about.... The new bush is fitted and now I can use any of the chucks from the Harrison L5a on the dividing head for work holding. Imagine a bar of metal in the chuck (a mandrel) with a blank gear mounted on it. Dead easy to cut any number of teeth on it. The clockmaker's friend Andy! Big enough to cut gears for a turret clock as well. Now, where are my drawings of the clock in the Houses of Parliament.......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 04/01/2007 : 08:13 Posted - 04/01/2007 : 08:13

A long time ago Newton Pickles gave me a pair of dividers made by a relation of his, J A Wilkinson, who migrated to the US in the 19th century but then came back. They are beautifully made and big, 18" overall. I used them regularly when I was working on boilers, mostly for casting out the hole locations on ver big blank ends. I never had to sharpen the points, they are glass hard. When I got the Birch lathe I found a large blued square made by the same man in the box of bits that went with it. It's hand-made by the same man and dead accurate. Whoever he was he had a pride in his job and was a good craftsman. I wish I knew more about him.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Another

Traycle Mine Overseer

6250 Posts

|

|

Posted - 04/01/2007 : 08:37 Posted - 04/01/2007 : 08:37

They look beautiful instruments. Would the Science and Industry Museum in Manchester be able to help with information on him? Nolic

" I'm a self made man who worships his creator"   |

TOM PHILLIPS

|

Posted - 04/01/2007 : 09:11 Posted - 04/01/2007 : 09:11

I love old tools Stanley,I used to spend hours on car boot sales rooting through the boxes that used to turn up,all were much better than the disposable rubbish they sell at B&Q.

"Work,the curse of the drinking class"  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 04/01/2007 : 12:42 Posted - 04/01/2007 : 12:42

Comrade, If I really dug I think I could find out something about him but at the moment I am satisfied with what I know about him from his work. The dividers are a joy to use, they fall into your hand and are perfectly rigid.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |