| Author |

Topic Topic  |

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted -

25/11/2004

:

14:20 Posted -

25/11/2004

:

14:20

|

I've always been fascinated by the things people do in their spare time when they can do exactly what they want to do. Men and sheds are a particularly fertile field. Women tend to do their thing in the comfort of the house.

I was delighted to see Andy's picture of the clock movement he has made.

It struck me that we could perhaps start a new topic devoted to spare time skill. So Andy starts it off and my contribution is this:

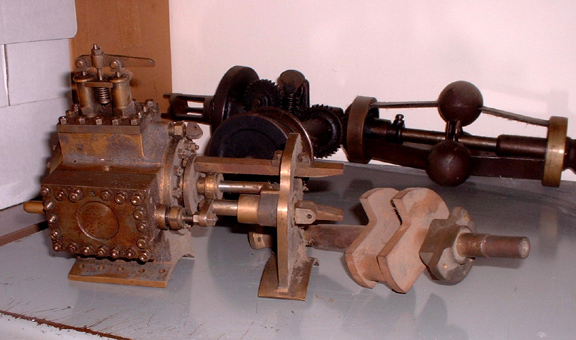

It's a small steam engine made from scratch and is based on the Stuart 5A but a longer stroke. One of these will drive a 14 foot boat with steam at 250psi. By the way, we don't like to call them models, it's exactly the same construction and materials as a full size engine, just smaller. So come on out there, let's hear about what you make in your spare time. I reckon we could be in for some surprises!

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk

|

|

| Replies |

| Author |

|

|

panbiker

|

Posted - 16/10/2007 : 19:33 Posted - 16/10/2007 : 19:33

Ringo, re the Penny Spitfire. It all started in this thread back on page 30 when I commented that I could never get on with a metal turning lathe, I always liked the forge at school and enjoyed bashing big bits of red hot metal about. I always wanted to make a Spitfire out of a solid lump of brass but was never allowed to have a go.

Steve48 posted that tinbashers like himself and some members of the armed forces during WWII used to make small Spitfire or other aeroplane brooches out of old pennies. I thought I would have a go at this but my first couple of efforts were a bit sad to say the least. If you follow the thread through you will see the various stages of manufacture (including the first attempt failures). Steve kindly bashed one up for me as an example and put the pictures and method up on his website here:

http://www.workshopman.co.uk/uphill_and_son/pages/engineering/metalwork/spitfire.htm

On the way to the finished spit we have discussed defacing coins of the realm and the potted history of the various metals and alloys used for coinage, anealing hints etc, quite educational.

My last effort was Penny Spitfire MkIII which finally emerged as the sweetheart brooch for my wife Sally. I had promised her the brooch in time for the Pickering 40's weekend that we recently attended. We go to quite a few of the 40's re-enactment events. I spent 10d in old money getting it somewhere near right. I think you missed it because you were engaged in discovering new members of your family.

Ian  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 17/10/2007 : 07:29 Posted - 17/10/2007 : 07:29

Today's task is deciding how much lap to give me slide valves...... I shall probably have a piston ring session while I calm my nerces. One thing is certain, the books on valve design come out today! A lot more complicated than it looks and I have decided to start from basics instead of just making them and chucking them in. Even if they are wrong, the engines will run but I want them to be right.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 17/10/2007 : 10:01 Posted - 17/10/2007 : 10:01

Well, I've done my reading, everything from Daniel Gooch onwards and have come to the same conclusion I arrived at 20 years ago, a dead simple equidistant valve with no inside lead and just a shade of lap on the outside. Not the most economical in terms of steam use but the one that gives the maximum of steam admission and the easiest exhaust. The only thing I did pick up from Daniel Gooch in the 1850s, which looks sensible to me, is to make the ends of the slide valve curved on the grounds that this gives a better lamination to the steam flow from the steam chest into the port. I don't suppose it will make much difference but I like it. The other thing is that I found the source of something I have always quoted as an example of how complicated the 'simple' slide valve really is.

SLIDE VALVE QUOTATION. CHURCHWARD.

'The action of the slide valve is not by any means an easy thing to explain simply; it is, in fact, a complicated and intricate matter to which many eminent engineers have had to devote years study. I believe it was the great G.W.R. locomotive superintendent, G. J. Churchward, who said that after 20 years close study of the subject he was just beginning to understand it. To those who are familiar with Churchward's work, that speaks volumes.'

[p. 24; Model Stationary and Marine Engines by K N Harris. Pub 1964 by MAP.]

The other conclusion I have come to is that my original preference for a threaded bridge piece to drive the valve was right and I shall repeat it in these engines. Using this means the valve floats free on its seat at all times no matter how it wears.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 17/10/2007 : 18:04 Posted - 17/10/2007 : 18:04

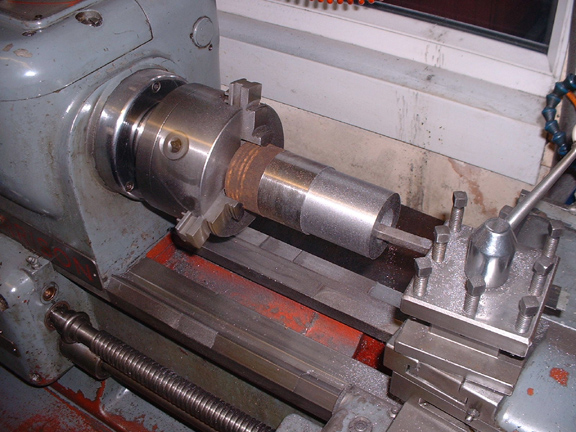

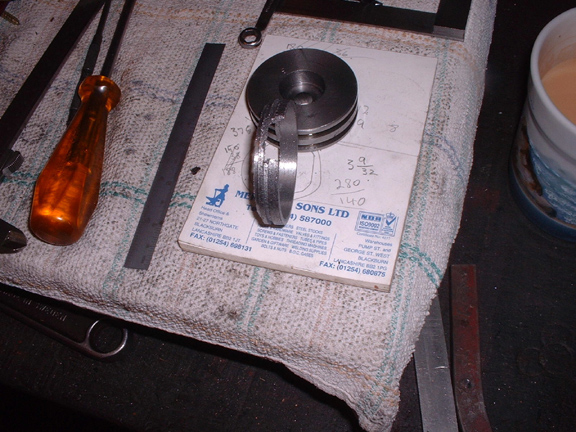

Piston ring making for the big cylinder from the casting that Newton made for me. Opinions vary about piston rings, I make them slightly bigger than the bore, these are about 1/32" greater diameter. By the time you cut the gap with a junior hacksaw it will squeeze down to less than the cylinder diameter but the act of springing the ring into the groove enlarges it so that when it is installed it presses against the wall of the bore but has a gap. Stagger the gaps 90 degrees and pop the piston in, never mind about the gaps, at the low temperature these engines work the rings will soon choke up with old oil and muck and the amount of leakage you get will be very small. We aren't driving 1000 looms! I've made the mistake in the past of trying to get the rings too tight and the result is too much internal friction until the bore gets quite badly worn. I prefer to have them running free and rely on the cylinder oil to complete the seal. Remember, at the speed this piston is running at 500rpm the air or steam hasn't much time to get past the piston!

Here's the big piston ready for popping in, dead easy just pressed it into the groove with my fingers and the engine still turns easily.

I went and had a furtle in the treasures for a bar of 2 1/2" bronze for the small rings and stumbled across this piece of CI bush which I had forgotten about. Just right for the small rings so here we are sizing it and boring the inside to just over 2" so at 1/8" square the rings just clear the bottom of the grooves. I'll finish the boring tomorrow and part six rings off. No dramas expected!

Ian, I had a look at your workshop today for the first time. Very clean! Isn't amazing how handy the tray under the mill is for temporary storage.....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 17/10/2007 : 23:07 Posted - 17/10/2007 : 23:07

Stanley

Studying valve design from basics, a brave man! I have a couple of reprints of American steam books from the turn of the 19th/20th century and they all seem to go for simple equidistant timing. Bit like "splitting the overlap" on valve timing for an IC engine with no available timing data, did it on several ancient sidevalves and it gave a good compromise.

I will be interested see your bridge piece valve-driver, my Yankee books show various types of sprung back plates for flat valves to accomodate wear and, allegedly, cope with water slugs, but no need for it with the duty that your engines will have.

Malcolm

|

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 18/10/2007 : 07:18 Posted - 18/10/2007 : 07:18

Slide valves are best left floating, the steam pressure will shove them down tight and if you get a slug it can blow the valve off the seat. It can give you problems though.... John's traction engine had a fault when you were just ticking over. It needed so little steam that the slide valve weight brought it off the seat and it just blew steam up the exhaust. Good for getting the fire going but lousy for slow running. I cured it by getting my mate Paul to braze a big lump of bronze on the inside of the lid and adjusted it to 3/32" clearance for the valve using lead wire crushed to measure it. Complete cure, it ticked over lovely and still left enough clearance to deal with water.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 18/10/2007 : 16:29 Posted - 18/10/2007 : 16:29

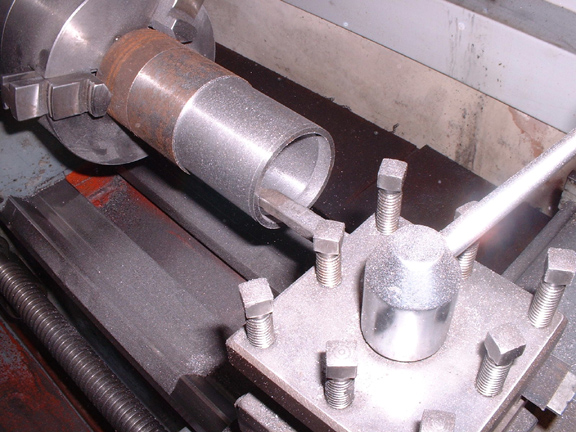

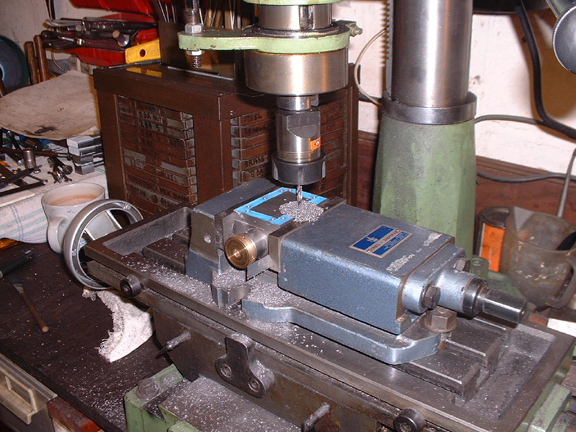

It's been a day of piston rings. Here we are taking the last cut in reverse to take the srring out of the tool. Then parting off.......

I hate parting off.... Here you see the combined results of a flaw in the casting and a parting tool that is cracked. A glorious bust up that lost me my centres and sent me back to square one.

Later...... 7 rings parted off and eventually two broke while fitting them. There is always a fine line between making the rings tight enough in their groove to seal properly and slack enough to fit easily. The bottom line is that all the cylinders have rings except for one small one. I shall turn two new rings tomorrow and then I'll have three to go at to finish the last piston. Rest of the afternoon spent shifting stuff so the decorator can start on the front room

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 19/10/2007 : 18:17 Posted - 19/10/2007 : 18:17

An upset day, decorators in and a new washing machine delivered. I had to take a door off as the new one is bigger than the old..... However, big does and little does the engines all have p[iston rings now and there are two spares. I have drilled one lid and steam chest and started a second one so we are still making progress....

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 23/10/2007 : 17:06 Posted - 23/10/2007 : 17:06

Nearly back to normal.... decorator is out and I have the front room to get back to normal tomorrow. I should be back in the shed by the end of the week......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 24/10/2007 : 07:29 Posted - 24/10/2007 : 07:29

I cracked and sorted the front room last night..... The return to the shed gets nearer......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 27/10/2007 : 05:18 Posted - 27/10/2007 : 05:18

Time for an update. I haven't been in the shed but today os flu jab day and once I have that over I am back to normal.... If you look at the pic of me drilling the lid and steam chest you'll see I drilled 2 holes on the narrow plane and 3 on the sides. The last one I made had two on each side and I thought it looked better with three. Then I realised that the middle hole interfered with central boring for the steam pipe! A bit of thought and I have enough room between the studs to bore for half inch steam so that's OK. One further point. If you look at many miniature engines, they have bored a hole on the corner of the lid for a stud. This was never done in main-stream practice, the corner was always left clear because of the danger of cracking the lid at this point. Only a small thing but people like me cringe when we see it. Bit like the positioning of stud holes on flanges. I have a traction engine cylinder upstairs that Newton made as a lad. His dad looked at it and told him he had too many studs in the lid and in the wrong place. Newton chucked it in the scrap box and never touched it again. I saw it and asked him for it so it got rescued......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 27/10/2007 : 05:31 Posted - 27/10/2007 : 05:31

All that work and one word from his dad knocked the steam out of Newton......

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

pluggy

|

Posted - 27/10/2007 : 10:02 Posted - 27/10/2007 : 10:02

The fact that you have kept it speaks volumes about you Stanley.....

Need computer work ?

"http://www.stsr.co.uk"

Pluggy's Household Monitor  |

Stanley

Local Historian & Old Fart

36804 Posts

|

|

Posted - 27/10/2007 : 11:48 Posted - 27/10/2007 : 11:48

It's part of Newton and his dad. They were such wonderful men. Johnny was the better engineer but Newton in full flow on a big lathe or round a steam engine was a sight to behold. No fear and total confidence in his own abilities. Some of the jobs they tackled were quite staggering. One thing Newton taught me above anything else is to weigh the job up and follow your own instincts. He was right, many of the practices which are taken as gospel because someone wrote about them somewhere years ago are totally wrong. We used to dit down and design steam engines and boilers that we'd like to make. I've told the sory before but in about 1980 we designed and built a combined heat and power plant for Vicarage Road and it cut his energy bills by 60%. We said then we should have patented it. I think Fiat did is a few years later. I reckon we had his diesel running at about 85% thermal efficiency, the best Rolls Royce ever managed with the Eagle was 50%.

Stanley Challenger Graham

Barlick View

stanley at barnoldswick.freeserve.co.uk  |

softsuvner

|

Posted - 27/10/2007 : 12:29 Posted - 27/10/2007 : 12:29

Stanley

The story about the cylinder is a fascinating insight into a father son relationship. Reading Newton's memories you can tell that he both respects his Dad, but is at times frustrated by his Dad's refusal to move away from the orthadox way of doing things. Although Newton discarded the cylinder, he never threw it away, he would have kept it as a reminder. At the risk of descending into psychobabble, the first man you measure up to in life is your own father. Nowadays they call it a "male role model".

Malcolm

|